Become a Creator today!Start creating today - Share your story with the world!

Start for free

00:00:00

00:00:01

3 Joey Gonzales of Steelblade Woodworks

A fun conversation with Joey about designing 3d products, upgrading his shop office, and lasering leather. We also discussed the benefits of buying the premium brand tools, and whether it's easier to upgrade to new software or keep the old.

https://www.instagram.com/joey.steelblade/

https://www.youtube.com/c/SteelBladeWoodworks

Things of the week:

Joey: Atlas roll up track saw https://www.instagram.com/atlasmachinery/reel/C_4QWKdJrhz/

Al: Annie Van Orman VW restorer https://www.instagram.com/annies_vw/

Jeff: Hueforge software https://shop.thehueforge.com/

and models https://makerworld.com/en/search/models?keyword=hueforge

Patreon: http://patreon.com/digifabricators

Discord: https://discord.gg/hHp8Sv7vt4

Recommended

Transcript

Introduction to the Show and Guests

00:00:12

Speaker

damn Hello, and welcome to DigiFabricators, the show where we learn how makers and artists use their computer-driven tools for fun, art, and profit. I'm your host, Jeff Stein, AKA a weird guy, and with me is my talented but humble co-host, Al Schultz of New York Woodworks. How are you doing tonight, Al? I am doing wonderful, Jeff. If I was doing any better, I'd probably have to sell tickets.

00:00:42

Speaker

Selling tickets again. Well, we got to make money one way or the other. yeahp That sounds like a good enough start. Let's throw in the disclaimer here and then we'll get started. Okay. Even though we pretend to be experts on the internet, I would like to point out that neither of us have any actual training and are just guys winging it in our shops and learning as we go.

00:01:07

Speaker

All advice provided is based on our personal experience and possibly inaccurate assumptions and is worth exactly what you pay for it. If listening to this show causes you to take out a loan to buy new and expensive digital tools, you may tell your spouse that it was our fault, but do so at your own risk.

00:01:27

Speaker

Okay.

Joey Gonzalez's Background and Journey

00:01:28

Speaker

So tonight we have a guest who uses his CNC to make fancy epoxy inlays. He likes to give his laser a digitally designed lift kit and designs 3d printed battery holders. So warm welcome to Joey Gonzalez from steel blade woodworks. How are you doing tonight? Doing good guys. Thank y'all for having me on. Uh, that was quite an introduction there.

00:01:56

Speaker

Hopefully I can live up to the hype. Well, i think you'll do just fine. well I believe it was all accurate, wasn't it? Oh yeah. i well Let's just say I've tried to do that stuff. I don't know how good it is, but you know, I've tried.

00:02:18

Speaker

Well, i yeah you're you're very humble, sir. You're very, very humble.

00:02:25

Speaker

ah You've obviously had some level of success, or we wouldn't have had any interest in talking to you tonight. So that must be some sort of an endorsement on its own.

00:02:37

Speaker

So in yeah other than the blurb that I threw out, why don't why don't you give us a quick rundown on, uh, uh, who you are, uh, what kinds of stuff you make and, uh, definitely what kinds of tools you got and what you like to do with them. Okay. Well, uh,

00:02:58

Speaker

quick rundown, I'm going to give you the long story versus a short story. So we've got, uh, this is long form content. You go as long as you want. Back in the day when I was a twinkle in my dad's eye, I'm just kidding. I'm going to, I'm going to start. Uh, I kind of got the, uh,

00:03:21

Speaker

The urge to do this back in grade school, uh, like most, you know, uh, everybody thought I was going to pursue what my dad did. My dad was a master fabricator, uh, metal and, um, everybody pretty much thought I was going to follow in his footsteps,

Transition to Woodworking and Shop Setup

00:03:39

Speaker

which, you know, I did help him a lot. Uh, a lot of the maker stuff that I get is from him. Uh,

00:03:46

Speaker

He basically one of those jack of all trades. He was a master of what he did. ah and And I learned a lot you know walking beside him and him showing me a lot of things. Now it wasn't woodworking, but ah the background kind of comes from ah my mother's side of the family. Her dad was you know a carpenter and whatnot. So I kind of like ah got the,

00:04:12

Speaker

got the urge to do that back in grade school. And then, you know, of course went off to college, did my deals, started my career, and then slowly back probably around 2007,

00:04:25

Speaker

eight-ish in there. My wife comes in and says, Hey, I saw this on Pinterest. Can you make it for me? And I was like, well, Sure, I can, but I need to buy some tools. I don't have some of those tools. You know, that website has sold so many damn tools. ah Yes, it has. Yes, it has. And she's like, OK, well, you know, we can we can do that. And so that's kind of how the shop started. My shop was mainly

00:05:00

Speaker

kind of like ah we used to do drag racing back in the day. So I was a motorhead, but we did drag racing with boats. We did the liquid quarter mile. So my shop was kind of set up. I had a TIG welders, stuff of that nature in there. ah You know, ah CNC, um CNC lathe, those kind of things that kind of were for that. So I kind of like switched. I was kind of out of that, getting out of that phase.

00:05:30

Speaker

And I started incorporating woodworking tools and that's where, you know, started building some stuff. And then ah we opened a boutique and she was selling, you know, women's stuff, but also I was making rustic furniture. And that's when I really, really got into it and we started doing that. And, and then it,

00:05:56

Speaker

Then I kind of got away from it because other things that I was doing in my life at the time, I had other businesses that were going on kind of like like Al, I had my side hustles that were ah bigger businesses, but also trying to keep my career going. So we had a lot of irons in the fire, as you can say. And then we, you know, fast paced life going missing a lot of the kids things. So we kind of like pumped the brakes and I kind of slowed down on the woodworking side.

00:06:25

Speaker

and paid more attention to other things that were going on. And then really back, up I was still kind of doing it, but I ah i would say from about 2015 to about 2017, I kind of slowed down. And then that's when I was able to, we moved to this new place and I built this shop and then it really,

00:06:50

Speaker

really went back into the full swing of things where I was like acquiring more things and and it's

Exploring 3D Printing and Online Sales

00:06:59

Speaker

really a hobby. I do i do sell some things online, 3D printing things. I'm all about trying to organize, building my new shop. So I'm always having that mentality of coming up with unique things to store your tools um and just clever ways to do things. That's what I'm about, I do have some items that I do put up for sale as far as like some silicone coaster moles, things like that. But the the main thing that I do do is on 3D printers. That's like track saw holders, battery holders.

00:07:39

Speaker

ah and And those have really been kind of what I have stayed with. Every time I get something different, I got to figure out how can I hang this thing up? How can I store it?

00:07:51

Speaker

to where it's just not sitting on your tabletop. And i do um I do do some laser stuff. Some of the main things that I do with the laser, I have made ah displays for businesses. So I know some people out in the in the maker world that they own businesses and I have made them ah items to display their products that they sell at trade shows.

00:08:17

Speaker

Uh, there's a few things that I make, like for Jake, I, I came up with those cup holders. Cause he was having Jake Thompson, Northside custom crafts. He, he does resin a show every week, uh, weekend on Saturdays. And he mixes a lot of resin, multiple colors at one time. So he's like, man, we need to make something so I can put all these cups. Cause he's mixing 15, 16 colors at a time. So.

00:08:47

Speaker

I was like, well, you know, I jumped into Lightburn and designed that thing for him. And then, of course, you know, advertisement for his show and and everything else on there. And those are kind of the, you know, solving problems. You know, I like to come up with things like that.

00:09:04

Speaker

Um, that's a good, I was just gonna say you're a problem solver. So though that kind of what really, uh, gets me going is trying to figure out things like that as I'm building my shop and, and coming up with unique ways to store things. Uh, you know, I'll, I'll look around and see what other people are doing and then maybe put my twist on it. Um.

00:09:28

Speaker

and And I've slowly been acquiring tools over the years. And, and you know, as far as out in the shop, ah I do, I have ah Avid CNC 4x4. We have the Omtec 80 watt laser.

00:09:46

Speaker

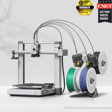

I have a bunch of 3d printers over there that I use, uh, recently changing over to the bamboo, which is, I think the best thing that has hit the market yet. Uh, you know, going from the old manual level 3d printers to.

00:10:03

Speaker

now where I don't even have to look at it. I just hit a button and it goes. I mean, yeah I would spend hours, Jake, Jamie, all those guys, they would sit there and just like, I would be why we were hanging out, you know, getting ready for either Jake show or, or the podcast, whatever. I'd be sitting there running runs cause I selling things and I'm having to sit there and manually level.

00:10:30

Speaker

those 3D printers out and and those sometimes it'll take. I got really good with them, Tori. would Pretty much I had that thing down to a science where I could make it print every time, all of them. um But with the bamboos, I mean, it takes the guessing out of everything. Super simple. It was really a game changer.

00:10:52

Speaker

um They're starting to come out with some clones of it now. There's some some of the other brands of starting to come out with stuff that they they print really fast. They do the self-leveling and there's some that are even doing the multicolor now. so yeah and But Bamboo broke that wall and pushed things forward in a huge way in several directions, and it was absolute game changing. And I'm glad I waited to buy a filament printer until they were on the market.

Investing in Quality Tools

00:11:28

Speaker

Yeah, it really opened open the 3D printing world up to a lot of people that that didn't that were scared to do it. Let's just say because of all the bad

00:11:42

Speaker

things that they have heard, you know, the trouble people have gone through ah trying to get one to print, you know, et cetera, et cetera. We go on and on about it. And when they came out with those printers, I was like, so many people bought them and are just loving it because it's so easy to use. They really took the thinking out of it. Really, you know, you just hit go and and and it prints. They work, you know, the success rate.

00:12:11

Speaker

is through the roof on those printers you know so ah moving out into the shop ah ah you know i have some of the tools you wanted me to explain i've got ah One of my first table saws was an old Powermatic 66. Love the saw. um it's It's a solid cast iron. I think it's like 52 inch ah cut capacity on that thing. It's a tank. I actually totally restored that saw about two years ago. um And a funny thing with that saw, you know, it it was hard down here where I'm at. I was trying to find the right yellow paint.

00:12:54

Speaker

And I finally I finally had ah enough trying to find it. So I just went over to one of the big box stores and I picked out some paint and I'm part of a powermatic group. And and when I put that song there, I knew I was going to get some slack for it. They're like. That looks like Ronald McDonald.

00:13:18

Speaker

color cat pat a pill yellow they They murdered me on that saw and I laughed. I, you know, it was, it was funny. I knew I was going to get, you know, those serious powermatic people.

00:13:30

Speaker

They were going to get after me. ah But that was ah that was fun to do that. I still use a saw. It's a five horsepower. It's an animal. um But I wanted to try to get the boys, my boys into here. So I do have a saw stop. I ended up buying that just for the safety feature. um we I have that saw as well.

00:13:52

Speaker

Um, and a lot of the other tools, I'm a, I'm a grizzly fan. So I have a grizzly 17 inch band saw, a grizzly eight inch joiner. I just recently got two pieces of equipment in. I bought the 20 inch spiral head planer. Uh, and I recently got a 24 inch double drum sander.

00:14:16

Speaker

which I'm probably gonna shoot some YouTube videos on those. um And then, um you know, I'm a big Festool. festival guys. So I got I got some fest tool in the shop along with the other ones, other other tools that I started with. But you know, people people will give you some some hell over those tools, right? And I'm like, look, guys, I I started back in the day where when I first started, I started with Harbor Freight tools and I still have some of my first saws.

00:14:52

Speaker

that I started with and and some stuff from Sears. I have the old Sears table saw and then I got a newer Sears table saw and it's just over the years, I believe you start you know at a certain I don't want to sound but bad with this, but you start at a certain level and then over the years you work yourself up, you start finding better tools at work that do the job better and you start investing in those tools. And that's what I've done over the years with that. That's really the most sensible way to do it. Um, I don't know if you, uh, either you guys read the Adam Savage book. no Every tool it's every tool is a hammer is his book.

00:15:38

Speaker

And in there, he he describes that the smart way to do the tool thing is if you just want to try something out and you don't really know what you're going to do with it. You don't know how the tool works. You don't know what the fancy advanced features are, let alone which ones you might want. And you might just be buying a tool and you might need to cut one board and you might not need a circular saw again for six months.

00:16:08

Speaker

In which case, do you need to go by the Festool? circular saw, no, that would be stupid. So you start out with a cheap basic model and then you can do the one project, you know, you need to do with it. And if you decide that you need to do more projects with it, then at some point you will start to realize that there are pain points with using the cheap tool and you'll know.

00:16:40

Speaker

at that point, you go look at the more advanced models and you can look at them and you say, okay, well, this one does this automatically and this one adds this feature. And now that you've actually used the tool and gotten a head start and have some basic understanding of it, you actually comprehend what those advanced features are, what they do, and you can make an educated decision as to which ones of those you want to upgrade for and which ones are just a waste of money.

00:17:09

Speaker

And if you're only going to use it a couple of times, you never need to upgrade it. But then if you find out you're just using it all the time, then that's when you go buy the more expensive tool is when you've used the cheap one enough to feel those pain points. And you've realized that there are crappy features on the cheap cheap model and they're holding you back.

00:17:33

Speaker

And that's when you go buy the good one. Anybody that starts out buying a Festool, if they don't know they want to do woodwork is an idiot. So yeah yeah all of us have got tools in the back drawer. And I don't think anybody should be shamed. I don't care what color your tools are. I care.

00:17:52

Speaker

what you managed to do with it. And I mean, that, that goes with whether, you know, it's like, I've got a handful of Ryobi's around here, but I don't do a whole lot of contractor kind of work. I don't need to use anything but a drill and a driver more than occasionally. So it's not worth the cost to upgrade for better quality because I don't need it. You know,

00:18:18

Speaker

I mean, I will, I will tell you, I, you know, sanding, right? Everybody loves to sand. Um, yeah and, yeah and, uh, for forever I use DeWalt products, right? And, um, it was finally on a work bench top that I built. I did a, uh, uh, epoxy inlay on it.

00:18:46

Speaker

And I sanded, I burned up a DeWalt sander. And I finally, that day I was out here, it was probably a hundred plus degrees in the shop. And when it burnt up, I finally, okay, I've had enough. I'm not gonna go buy another one. And instead of, I could i could have ordered, that was the first Festool product I bought was a sander, right?

00:19:11

Speaker

And, uh, I didn't want to buy it online. I've heard people talk about them and there's, you know, you got festival, you got Merka, you got surf prep and, but got in the truck. We were going to take a trip up to San Antone. So that's about two hours away for me. So I went up to Woodcraft and I touched it, felt it, looked at it. And I said, okay, I'm going to try this center. They're all compared Lee price, really. It's just what color do you want? So.

00:19:41

Speaker

um I bought it, best decision I ever made. I mean, my hand was not getting numb. How quick it sanded, I was like, why did I wait this long? The pain that my you know that you would go through and you use one of those sanders and it's like night and day difference. it's like i'll um you know That sold me.

00:20:09

Speaker

right then and there. yeah I was like, you know. um It was a different project, but my story is almost exactly the same. It was tabletops, but no, not epoxy. And I was a Makita guy. And because to all I did have problems with the vibration in my hands and stuff like that. And I burned up a Makita, which was my third one. And we.

00:20:33

Speaker

Fortunately slashed. Unfortunately, I have a Festool dealer 20 minutes from me, which is not meant necessarily a good thing, but I went down there and I was like, listen, this is a problem I'm having. You know, what do you got? You know, yada, yada, yada. And he put me in a, um, he put me in a 125 and, uh, he said, take it home. He goes, I want you to use it for 15 minutes and then tell me if you want to buy it. And I was like.

00:21:01

Speaker

This is the most ridiculous sales pitch I've ever heard. Yeah. So I went home and I plugged that thing in and I used it for five or six minutes and I called him and I said, I'll be back tomorrow. I need these grits and sandpaper, yada, yada, yada. And we, he kind of, he's a really good guy, not just a good salesman, but he kind of explained it to me. He goes, go to a big back store and, and price a quality Sander, a DeWalt or a Makita, or, you know, I don't want to bash any other brands, but those are probably the better quality one, Milwaukee even maybe. right um He goes, you're going to get this particular sander is going to last to five of those sanders. He goes, now, how much does five of those sanders cost? Almost twice what this one cost.

00:21:54

Speaker

You know, so it actually for longevity and and and all that kind of stuff. It's almost I'm not going to say it's cheaper, but it's. Financially or fiscally, it's you're actually saving money in the long run by going with a higher with a better quality tool. And that green Kool-Aid tastes really good. You know, you're saving yourself a lot of headache and frustration along the way, too. Yeah. See, I haven't. I haven't got to the third level yet. I'm still on, I guess that the the lower end of level two at this point. You know, I, I went through my Ryobi Sander, which was the most God awful, horrible piece of junk I've ever owned. And I was happy to put that down. And I think I've got a Bosch.

00:22:58

Speaker

So I think I went with a Bosch, which yeah I count, you know, sort of kind of the low end to mid grade. It's a little bit down from the Milwaukee's and the DeWalt, but it's still not at the bottom end of the Harbor Freight and Ryobi end. So I just, I just haven't put enough use into sanding or anything to really hit that third level yet, but It's all about buying the tools you need. And it would be silly for me to spend $1,000 on a sander that I use 10 minutes a month. you know yeah Well, ah i'll give you I'll give you a little insight on it. If you ever want to get one, go on to Festool Recon one and done.

00:23:49

Speaker

Okay. That's their discounted tools. Now it's not because they were used. Somebody may have taken it, but majority of the time it may have a blemish.

00:24:02

Speaker

or something and they send it back, Festool goes through it and then they sell it at a discount, right? And you can get a lot of their products, $100, $200 off. Now, I will always tell me if somebody wants a sander, I say go get the, go get the ETS 125, which is their five inch orbital sander and you try that sander, which is going to be comparable to your DeWalt orbital sander. And you tell me which one is best and that makes you a believer because that little sander is phenomenal.

00:24:39

Speaker

and and and you could i think it's on recon right now they have one and it's hundred and ninety nine bucks for that sanders yeah um and it's hell of a sanders it's a damn good sander you're you're not goingnna you're not goingnna clear go ahead No, I'm sorry. I was going to say they're just bumping 300 full price or not. They're yeah not a grant. Yeah. And and and it's a good quality, Sandra. I tell them, go try that. And then you tell me what you think. ah yeah and and And a lot of people, it's like, I have some DeWalt.

00:25:12

Speaker

cordless sanders and those things are so um they're unbalanced and if you don't watch it because that battery's hanging off of one side you end up putting divots in your material and stuff so you got to be really careful and then they start getting real hot and the vibration it just kills you that little sander uh that 125 it's a dream like for laser stuff I mean, that's what I use it for. I pull that thing out and stuff coming off the laser. I hit it real quick. Perfect sander for that. It's nice. Very nice center.

00:25:50

Speaker

now i think the one i would actually get some mileage out of is because your're you're talking it yours is just the the the flat bottom random orbital right is that the one we're talking about okay and i see i've got a lot less use for the sand it flat than i do for the uh sand the grooves out of a 3d carve so these little i see like i think surf prep has one of these little ones that's got the like the sponge the sanding sponge on the end that vibrates and that that kind of thing is supposed to do just the same kind of wonderful stuff except for small like detailed curves to do like reliefs or 3d

00:26:39

Speaker

that I would see some I would get some use out of that one a lot more than I would see any value out of a random orbital. I don't do a significant amount of flat things compared to the percentage of of curved surfaces that I need to sand seems to be a lot higher. Yeah, that's. Well, Festo has a not that small. That's the ray that surf prep has. And I've been eyeing that standard because that is a nice little sander. It looks like it's very compact, it looks. And with that sponge on there to get into grooves and profiles,

00:27:21

Speaker

it's good now you can uh i have one of the fest tool uh i think it's a three by five which is kind of sort of like it but it's a lot bigger uh and you can use surf prep yeah surf prep actually sells a conversion of a sanding sponge that'll go on that sander and i believe you can get them through festool and probably some third party companies as well but That sander is a lot bigger than the rate. And if you want a small from what I seen, I haven't been up close to one. It's very small and easy to to use. So for like what you're trying to do, yeah, that's probably that surf prep is probably the way to go, you know, for your application. What's that one going to run me?

00:28:13

Speaker

I want to say that that's sander with the whole kit is you're probably looking at about 700 bucks, 700. Don't quote me on that. You know, if you get the whole container and pads and sanding paper and all that stuff.

00:28:29

Speaker

for For that much money, I'm gonna spend an extra 45 minutes using the normal handheld sanding sponges. yeah because i've got I've got a few boxes of those. i just that's That's what I do a lot of my work with is sanding sponges right now. um wait you make a real You make a really good point and you kind of and you brought it up in the comment a few minutes ago.

00:28:59

Speaker

Jeff, sorry. Wow. Let me try that again. You made a good point a few minutes ago, Jeff, and that was that like you should enter at your level. You know, you're not going to give a 16 year old an $80,000 pickup. You know, you're going to give them a, you know, a 74 Chevy and let them take care of it and learn how to drive it and all that kind of stuff. But.

00:29:22

Speaker

um To your point, you're not at a place where you need to have a $700 sander because you're only sanding five or 10 minutes or 15, 20 minutes, whatever. you know So you can't justify justify that cost yet. But when when you get to that point,

00:29:41

Speaker

You know, then it's, then it's almost cheap to, or I and don't like to use word cheap. It's inexpensive

Art Pricing Challenges

00:29:48

Speaker

to do. Cause it just makes sense. You know, right that also presupposes that you actually make money in your shop at all.

00:30:00

Speaker

Which at this point, I'm simply funding my hobby and having a good time down here. And i I'm apparently 95% artist and about 1% salesman.

00:30:19

Speaker

um aye I couldn't sell water to a fish in the desert. I don't know what it is. I just I haven't got the mentality to find a product, find a market and find somebody that'll actually give me their goddamn money. That's that's apparently not in my skill set. I can make the coolest shit. But see, the other part of the problem for me, though, is that I'm making shit that

00:30:51

Speaker

doesn't have a sensible price point. Because if you make art that takes, say, 20 hours of CNC carving time to create a piece, and you've got two and a half or three weeks of work into this project end to end,

00:31:12

Speaker

But you come out with them you come out with a gorgeous piece of art, but the thing's less than six inches tall and how much is somebody going to realistically pay for that? And the answer is not enough to justify what I went through to create it.

00:31:28

Speaker

Now at some point I may hit this artist point where people will just pay money just to have something that I made, but I'm not going to hold my breath and it's certainly not happening this year. And I mean, if, if I make something that's cool and it looks like a $60 object, but I've got 20 hours of labor into it.

00:31:53

Speaker

that isn't a sensible business prospect for me, you know, at that point, if I have to put that much effort into it, I'm either going to want to sell it for 500 bucks or a thousand bucks, or I'd rather give the damn thing away to somebody and say that I gave away a thousand dollar piece of art because I think that's what it's worth. And I was happy to give it away versus It cheapened myself, my work and my art by taking 60 bucks for something that has way more value and input to it than that. So the the problem is, is that I make. $60 pieces of art that take me weeks and weeks to do, and there's just no way to pull that into a business model. I can't.

00:32:50

Speaker

I mean, I can make dumb crap to sell, but I wouldn't like it. Well, you know, and and if it's a CNC file, you can go at it a different way. if it If you make it and it's a cool carve and people like it, then you just turn around and you load the digital file and that's there forever. And that's making you money all the time where they can just buy it, you know, the file, you know, ah at that aspect. And then then that's a way you use your carve to market that file and sell the file.

Designing Battery Holders

00:33:24

Speaker

That makes sense. Let me ask you a question, Joey. The understanding that you're from Texas, and i've I've seen you pan your camera around there. One, how big is this shop you're in? Because I'm assuming there's a, it looks like bigger than a double wide trailer inside your shop.

00:33:45

Speaker

but but but the main question is I'm just curious about those dimensions but the main question is this this room that you're sitting in is beautiful we should really be recording video but explain how if you can Easily and into a simple-minded person like myself like like you say you make you use your 3d printers and your lasers to make To problem solve things hang a festival battery or hang a saw track or hang a thing. How once you see a need What's what's the what's the steps these like? What do you do you sketch it out on a napkin and then take it right to a ah printer? Like how does this work?

00:34:26

Speaker

Okay, so ah like the battery holders, for instance, right? I'll jump in a 3D design software. And I- You're allowed to say what? It's called 3D Builder. It's a very, basically the simplest version of 3D design that I think anybody can use. I don't use any kind of special software like Fusion or of shape our Shaper I have tried, I just don't have enough time to sit there and try to learn it.

00:35:04

Speaker

this thing is a very simple simple software and i have been using it for years it's free and i just get a set of mics or a set of calipers digital calipers and i start measuring the battery and it's basically a simple design software where you're taking blocks and circles and you're merging them, subtracting them, and I build the design. If you were to sit there and watch, there's probably a very more simple way, but it would take probably weeks upon weeks to master a different software that would get me to the same endpoint

00:35:49

Speaker

where I can do it in probably a few hours, because I already just know how to do it. I know the steps. and And I always, when I design something, I challenge myself to get it on the first try. That thing better fit when I get the first print off the printer. And I've only had one that I've not been able to do it with, and that was the Milwaukee M12 batteries.

00:36:17

Speaker

And the only reason that I did not fit that is be because it didn't fit properly because I didn't take on that battery, it has a little nose on the end and I forgot to subtract that part. That was the only reason it didn't fit. The actual fit of the battery was perfect. It just didn't go far enough to reach the locking mechanism. And when I looked at it, I was pissed at myself because I forgot to take that out.

00:36:45

Speaker

And that really hit the wall that ruined my it just didn't go in enough to lock in it. Yeah, it hit the wall. It did hit the wall. I was going to say you missed that one. Yeah, no, I did. I got it. I got it. I got it. I got it. My failed prints go off that direction somewhere. You know, that's I think that's the standard thing to do with failed 3D prints, whether it's just not good enough or whether it was actually failed or yeah, that way.

00:37:14

Speaker

i I screw all my, if I mess something up on a CNC, I get screwed to the ceiling. So every time I lean back from the desk, I go, oh yeah, yeah. but but so So the one I failed on, I rode in black Sharpie.

00:37:27

Speaker

don't, it was other words, but basically don't do that again. You stupid ass on there, you know, and, uh, and it sits right there when I'm, when I'm doing it. Uh, and, and but I mean, that's when I get like, I get a new tool and I look at it and I'm like, okay. And I'm in the right state of mind. I come and jump on the computer and I sit there and I started hacking away and, and I get the design.

00:37:54

Speaker

And once I print it, it fits. I try it like the track saw holders. Those were things that I went through test and test. And I have some that I've.

00:38:06

Speaker

only showed one reel a long time ago, but I have not put out. And I think it's a, it would probably, well, every time I think it's something good, it's like, eh, you know, it doesn't it doesn't move. But um I designed one that's basically, it holds your tracks vertically, but they clip in, right? And I did it last year and I never pulled, I never brought it out to the public.

00:38:33

Speaker

Basically, it's still sitting in the shop and i've let it sit there to see I test my stuff at the texas heat because I don't it's not um climate controlled yet. I have the damn ACs and the insulation sitting out there. I just never have done it. Uh, and I want to see how that filament is going to hold out there because if it's going to fail, it's going to fail out there when we start getting up into those 105 degree days, you know? So if I'm going to sell somebody something to put a $400 track, saw track on there,

00:39:08

Speaker

You know, it better damn well hold it, you know, so those I test them. I test the hell out of them. I test them to see if somebody just grabs it and pulls it out. Make sure it's not going to break that that they'll hold up. And yeah and then once that's done, then I.

00:39:26

Speaker

put them online, you know, I use Etsy. So this, you know, so forgive me, I'm, I'm not the, I'm not the tech guy here in this room. That would be Jeff, but I just have big tech toys, but I'm going to, I'm going to download this 3d software. Are you talking about? fish But so I was always under the assumption that you made a product, not you, but a person or a company or whatever makes a product with a 3D printer, like a prototype, like this works, make sure that the dimples in the bottom so the battery slides in. And then from there, you would go to a production company and make them. I didn't know that you actually used the filament based pieces. Like I didn't know they lasted. I'm assuming now that if they're living in Texas, they got to be pretty tough.

00:40:15

Speaker

Yeah, that actually leads to my question, which is ah what you were worried about strength test. ah What kind of plastic, what kind of filament are you using for these that is going to be good enough to not break on your customers? Now, if there's something that's in stress, like, ah for instance, the clips that hold the power cord to your ah vacuum hose, right? I leave those with a little tension so they just don't start wrapping around as you're moving constantly. Now those PETG is good. um PLA won't last. PLA will end up stretching on you. um For the track saw track holders, I've got them stiff enough to where I do use PLA. I haven't had no issues with them. ah The only issues I've had is

00:41:08

Speaker

when in shipping and I've changed that because I used to send them in bubble wrap bags and of course when they get go through the shipping process they get demolished because they get probably put under hundreds of pounds of of weight and I've had I've had three sets that have been messed up but other than that I've had no issues uh with that at all um but it's p a ptg and um

00:41:41

Speaker

Yeah, you would have asked me and I can't think of that. There's ABS. Yes. There's. Yes. Yes. That one. ABS. Is it ABS? I believe it's ABS.

00:41:57

Speaker

Yeah. Could be. Let's just go with that. Let's go with that. That's nice. That's the one that's really hard but has a little bit of flex given to it. PLA Plus is another one that I use. OK. Yeah.

00:42:12

Speaker

that as far as I understand, that really means just about anything. That just means that they've taken the PLA and they've added some shit into it to make it do a little something better. But yeah, every company's plus is their own proprietary mix of who the hell knows what. And and for all we know, it's all the same shit.

00:42:36

Speaker

To be honest. Yeah, for the most part.

00:42:41

Speaker

Yeah, I'll tell you a story, the old the ah the ah all the same shit. I lived out in the Midwest, out in Kansas. I was born and raised here but in New York, but lived in Kansas for several years, building service stations, petroleum field. And the owner of the company's father was an old Philly Phillips 66 jobber, like work factory man, you know, company man. And when he started I don't know, this was probably back in the thirties. They, all Phillips 66 stations were full service. So you pull in and five kids, you know, five teenage guys in suits and caps and you know, they're all dressed to the nines. They'd come running at your car. You know, they got the windows going and the hood open and all this kind of stuff. And you need oil? Yep. What kind of oil you use? I use five weight. Okay. And they go on the back and he pumps out a quarter, five weight and everything. And next car comes in, what do you need? Oh, I use 10 W five or whatever. Okay. We got that. He goes.

00:43:35

Speaker

It all came out of, they had one 55 gallon drum oil and whatever kind you needed, that's what it pumped out. yeah convenient And he said, Phillips 66 had one barrel of oil for 50 years. Not, not one barrel, but that's like every station had one kind of oil. It was all five W 30, whatever you asked for, you got five 30.

Shop Expansion and Product Testing

00:43:59

Speaker

Yeah. Just like, you know, you, it's funny you say that cause I've got friends that, you know,

00:44:03

Speaker

work in the refineries down here and i and I asked him, I said, what's the difference between red dye, diesel and yellow and regular diesel? There's no difference. Nothing. All it is is one's taxed and one's not. We put the red dye in it so they know that it's non-tax and the other one's taxed. and And there's no difference. There's no difference. ah Just don't get caught with that in your in your vehicle because that goes by the gallon fine and it's very expensive.

00:44:32

Speaker

I never have. um I didn't do that. Yeah. But there was a there was a gentleman that back in the day got caught. It's it's all ranching, farming and ranching down here where I'm at. And his truck didn't have enough fuel to get to town. So he pumped some red dye. And it just so happened that before he went, he went straight to the auction yard.

00:45:03

Speaker

so to go through the cattle sale before he went to fill up the truck. And it ended up they were dipping tanks there and got caught with 10 gallons of red diesel in his pickup truck. And he didn't have farm tags on his truck. He had regular tags on him. And that was a very expensive lesson that they caught him with that.

00:45:26

Speaker

I've heard those find some, some of those DOT guys would, they'll, they'll find you for the fuel you don't have in the truck because prove you didn't run a full tank. Yeah. know and It depends on the person, right? And, and, um, how, uh, how crazy you get with them, right? You know, uh, but that's, they, they'll take the time to, you know, to dip the diesel tanks and, and especially like in semis and stuff like that, when,

00:45:53

Speaker

you know, when the oil boom was really going and DOT was doing inspections, the comptroller over there and they were dipping tanks at those weight stations, making sure you didn't have red dye because a lot of people were running because you can get it a lot cheaper, you know? yeah yeah Got to be careful with that. but and And them semis, I didn't care out there. Them, them boys run for four, 800 gallon tanks, you know, four to 800. I would want to pay that fine.

00:46:23

Speaker

no Hard pass. Yeah. So we're gonna buy the good gas explain what this fancy room that looks like a 3d printer rave going on behind there.

00:46:36

Speaker

my voice activated lights. ah they This was, I don't, you probably, you know, Keith in working hands, working hands podcast. yeah Yeah. So this was, this was a, yeah. They did their, ah contests at the beginning of the year, make what you fear, make what you fear. Yep. And, um, I added onto the office. Cause when I first built this, this, uh, uh, by the way, you asked the question, this barn is 40 by 80. Um, I have, uh,

00:47:13

Speaker

1600 square foot as my shop, and then the rest of this is office and I've got a full blown apartment that my son lives in right now, um which I don't know, I forgot what the square footage is, but we built all this. The barn we didn't, the barn was actually built by somebody, but the interior part the, it's a full blown house in there. I mean, kitchen sink. I mean, it has everything we did that me and my boys did it. Um, and this office, when I built it, I was like, that's going to be plenty. I don't need anything bigger because I wanted to have more room out there. Well,

00:47:51

Speaker

It came to a real pretty months. Yeah. And I started getting more 3D printers and then the laser and it's like, you know, it was just very claustrophobic in here. And I was like, I need to expand this thing. I didn't want to because where that office, it is where my CNC was. So I was already like halfway done with building my shop out. And I had to tear it all down.

00:48:20

Speaker

to extend this office. And ah it was good to do it because now I've got plenty of room in here to buy more toys, I mean tools. But when I, you know, when I expanded this, I did that for Make What You Fear. And the reason I did that was because I know I'll procrastinate a lot and I'll start something and then I'll I have a squirrel moment and I'm off to the next shinier thing. Right. So oh yeah I was like, I've got three months to build this and I wanted to challenge myself. I wanted to see if I could do it in three months because it may not look big and it's not big. I think we were, we just talked about this on our podcast a while ago. It's 12 by 14, I believe, or, or oh massive 14. No, it might be 20 by

00:49:16

Speaker

12 or something like that, right? It looks big on camera and it, it, yeah you don't think it's big, but it added a lot of square footage in here, but sure when you start, but and I had to tear this wall down and mind you on top of here is all storage. This, this whole, I mean, it's all whatever is left in here. So there's a lot of weight. I got a lot of storage up there on top of this. So I had to build a beam. Um,

00:49:47

Speaker

tear the wall down and then finish all this in three months, rerun, reroute electricity. um I mean, there was a lot of crap to do and I got it done in the allotted time and it just, you know, just, it's a lot of work and that kind of like, the reason you haven't seen a lot of my stuff is because after I got done with this, I was like, I took a hiatus. I was like,

00:50:15

Speaker

I need a break from this stuff because because it was a lot of work. I don't know how you keep up with all the stuff you're doing as it is. yeah know it ah I tell you what, there's there's an underlying theme here. I don't know if you're if you've heard it or if you're picking it up on your own thing there, but like I've heard you say two or three times now that you challenge yourself. Like you got it when you do a 3D project, it's got to work the first time you gave yourself a three month timeline and you got it done. Like that's a that seems to be a very important task,

00:50:50

Speaker

a mastery of task, if you will. um Do you think that is How you maintain like, like just like, let's face it, we're, none of us are the three youngest chickens in the coop here. Um, you know, so how do we stay sharp in this ever changing world? Like, do you just keep saying, I'm going to learn a new thing today or not? I'm going to do a new thing today or, or how does that work in your mind?

00:51:16

Speaker

Yeah, well, you know, and part of this, I wanted to see if physically I could do it because we're not, again, we're not young and we're not the healthiest or I'm not the healthiest of persons. And I wanted to see if I if I still had it in me to do something like that. And I still do. But I wanted to see because I had no help. yeah Well, I will say my son helped me lift the beam.

00:51:41

Speaker

a little bit because it was kind of physically impossible for me to try to do it. But other than that. I did it all, all one, one person. And that was a lot of work. That was a lot of work. ah You know, the finished part, it's easy, you know, it's easy to do like the framing electricity. It's not that big of a deal. But when you start doing the finished work for it to come out and look nice, that's what's ah

00:52:15

Speaker

what's the hardest part, you know? And and I challenged myself. I wanted to to try new things that I've never tried, ah yeah making all my own case molding, doing the shiplap walls. It was a it was a ah something that I had seen years ago on YouTube. And I didn't want to go buy a shiplap because it's expensive. And I was trying to keep this in a certain budget. um And I had a bunch of ah three eighths quarter, no quarter inch ply. And that's all quarter inch ply spaced with the nickel, a US nickel really spaced in in between the plywood and looks just like shiplap. I'd seen them do it a long time ago and I was like, you know what?

00:53:00

Speaker

I don't want just sheetrock walls. I want to do this. And we had bought a crap load of plywood years ago for hurricane season. We just stockpiled it and it's just sitting back there. And I'm like, well, I'm going to use some of that now. Cause it's just sitting back in the back barn behind this one. And I'm like, I'm going to pull that stuff out and use some of it. And that's what I did. And it came out, it looks real nice, but.

00:53:28

Speaker

Yeah. I mean, when, when you back to your question, you know, challenging myself. Yeah. I just, that keeps my head, you know, trying to keep my, and keep sharp, sharpen my skills on a lot of that stuff. Cause some of that stuff's pretty challenging. Like on those 3d designs, um, you know, now you could get a, a 3d scanner, which would make it easy. You could put that thing on there and you could pretty much, and I've thought about buying one and then I like,

00:53:57

Speaker

then what's the fun? What's fun? in it ah The challenge is modeling it to make it right. Not well. And i'm well, we'll see. Here's part of the deal is that you wouldn't be able to be you can't model something you don't have. I mean, you can't scan something you don't own. You could scan the battery.

00:54:20

Speaker

and import that, but you'd still have to model the holder to go around it. It would just give you a little bit of a visual head start on the measurements, you know? how well are they Well, like in the software I use, it would make it so simple because once I scan the battery and I bring it in there, then I would just take a square block and stick it over it and subtract the battery out of it. And and it would leave me the actual imprint of the holder there. right The way the software I use works. That's how you would do it. But then what's the fun? What's the challenge? Right. Yeah, I could design something in probably a matter of minutes, you know, but to sit there and design it and challenge myself and get it on the first try. That's what draws me to it.

00:55:17

Speaker

That's why I like to do it.

Sales Strategies and Aesthetic Choices

00:55:20

Speaker

Can you generate STL files with that software? Yeah. Yeah, 3MF for STL. I gotta try this.

00:55:30

Speaker

You're probably going to be like, just do the show notes where you're probably going to, and I've told a lot of people it's three and builder by Microsoft. And the reason I use that is because my first 3d printer I ever bought was a Dremel 3d printer. I still have it. That thing is so freaking loud. It sounds like it's going to fall apart.

00:55:50

Speaker

And, uh, when, when my wife had the boutique, we were, we used to make shirts. We got into the shirt deal, had all the heat presses, the, the printers to print the, the transfers, all that stuff. Well, I had a bright ass idea. Hewlett Packard came out with the computer called the sprout and it has a 3d imaging deal that comes over the top.

00:56:21

Speaker

And you could put your stuff on a plate and it moves it around and it'll take a 3d image of, of whatever. And then that computer, my whole thing was when I was going to get a laser back in the day, I wanted to, uh, and a CNC, I want, wanted to make, um, Pew pew handles.

00:56:47

Speaker

Uh huh. I don't want to say I don't want to say I don't know if we're allowed to or not. That's fair. And the whole deal was was to take the handle off of the pew pew and 3D model that to where I could then transfer that and use it on the CNC. Right. OK. That threw me into the 3D. Realm.

00:57:14

Speaker

And I never went the other way. Another squirrel moment. I went sure opposite. And now I'm doing what I do. ah So that never I've never done that. I still want to do that at one point. when Yeah, I just I just jumped into the the fiber laser world for that particular reason working on those particular items. Yeah, which I'm now now I'm finding out that ah There's all kinds of rules and stuff about you know, how you store them in your shop and ah Yeah, well, just people I don't know if y'all know this but I do leather work Yeah, I've got a I didn't know I have a whole leather Set up. I got a big leather sewing machine. So I used to make a

00:58:06

Speaker

uh, holsters and I found out that yes, you have to be licensed. So what I would do when a customer would come over, I would, you're going to sit here and let me get the design off of that certain item. And then you've got to take it out of here. Take it out of here. Yeah. You know, right. That's fair. You know, and you can buy the blue, the blue, you can, you can get those models already made identical, but they're expensive. You know, they're like 50, 60 bucks a pop.

00:58:43

Speaker

And I didn't have enough work to to justify buying that, you know, it's really too bad. We don't know anybody with, I don't know, 53D printers. yeah these and that was That was one of the the the the deals that jumbling around in my head that I could do that myself, you know, right? Because in the whole fitting process, when you get the leather wet and you want to form fit it. um Yeah.

00:59:12

Speaker

you know, you put that under pressure and it form fits that leather to it to, to get a, you know, to get a fit on that. Uh, I forgot the style they call it, but, uh, yeah. Uh, yeah. That wet farming is cool. Yeah. yeah and And I love doing it. That's just like another thing where I can just sit there and I just, I got a lot of little things that I do that, that the leather part, I think I did some stuff on, uh,

00:59:42

Speaker

on, on that, uh, what was it that Jamie put on? Oh, what was it called? Um, it was a deal they came up with when COVID was around where they did that ah virtual craft festival. I did some shows. We had an hour segment and I did some leather stuff on there. Um, like how to make a knife scatter, you know, things like that. But You're making any aprons. I need a new apron. No, I dude, I sweat too much to put one of those on, man. I would that thing would have mildew all over it and stuff because I just like no way I can't wear one of those. So do you ever do do you ever mix your chocolate and your peanut butter? Do you ever get your digital tools involved with the leather? Do you throw leather in the laser or anything? Yes, I have.

01:00:37

Speaker

Yep. I have made I hear it works. Well, smells great. Love the smell. See, I used to. I used to. I love the smell. A lot of people don't. I love it. When we used to brand all my cows, that was my favorite part is branding my cattle just because of the smell. I call me crazy. Call me sick. I don't know. But that just kind of barbecue kind of flavor. Yeah. Yeah. Yeah. A hot iron hot iron going up. ah on the side of cowhide, but when you put it in here, it just bring back memories. I'm like, you like that smell? I said, I love it. I could sit here and just burn leather on that thing. It took me a little bit to figure out the settings, but it's the greatest thing. I'm like, man, that smells, smells wonderful.

01:01:26

Speaker

Now, is there and is there a quick and easy trick? I'm sorry. Is there a quick and easy trick on those settings for anybody that wants to do it? You just got to feel for it. You you probably like on this laser. ah What was it? ah I think around 20, if you want to just etch like around 20, that's an 80 watt laser.

01:01:54

Speaker

run about 20, 25% power and on on for engraving on it. And then when you cut, I do probably around 30% power at probably, I wanna say, what was it? What would I run it at? Like 40 on the speed? Am I saying that right? That's pretty fast.

01:02:24

Speaker

And that's cutting well that's cutting, that's cutting through like about a five to six ounce piece of leather. Yeah. And if you get up a little, a little, I got to clean my lenses cause I don't think mine would do that. And it's a hundred watt. ah stuff Oh, it'll go through it out. Easy. It'd be like cutting butter on that big old monster you have. It's not that bad. You, you play with it a little bit. I, it took me, all I did was just cut circles.

01:02:53

Speaker

until I finally got it to where it's not scorching it. And it's more of a rosy color. But you use that, oh, what's that cleaner? um Awesome. What is it called? Oh, LA Awesome. LA Awesome. Love that stuff. Clean the leather. That's a dollar store thing, isn't it?

01:03:15

Speaker

ah You can get it at Lowe's now actually. Yeah. So if you do, it's super cheap. It's going to be next to the Fabroso. Fabuloso. Yeah. If you etch leather, LA Awesome, the greatest thing cleans it, makes it, you know, cause you're going to have a little bit of charring on the etching and it'll have a little sut. Just use LA Awesome to clean it off, be golden. um Works, works like a charm and then you can put your oil or whatever you're going to do to Yeah. Cool. Yeah. So how many how many 3D printers do you have hiding over there off camera? yeah I just gave my my little cousin. He's gotten into 3D printing and he's real big into the airsoft.

01:04:23

Speaker

take them, give them to them. They're but they like cool nearly brand new and I know he loves it. He just actually sent me a message right before I got on with y'all and he's like, what are the settings for this? And I popped them off to him because he's over there. Man, he's tickled pink right now. He's got two, three, he's got They bought him one for Christmas and now he's got two more. So he's got three with the two I gave him. So he's like, he's in heaven and he sells the stuff, man. So he's like, he got into it and he's selling all his people that are in his little deal, all these accessories and he's like making money. And I'm like, dude, go for it kid. Get after it. Nice. Get your hustle down. There you go. I guess I'm going to have to break down and buy one of these things. Oh, Al, you'll love it, man.

01:05:10

Speaker

Well, I gotta say the, I hear the a one mini is on sale right now. It's like, what I think it was like 200 or 250 bucks. Uh, and for the mini was just, it was only a couple hundred bucks and it's like $200. I think you can get a mini with the mini version of the AMS for like.

01:05:35

Speaker

three, 350 boxers. It was really low entry point for a bamboo system that does everything for you. I got an A1 mini sitting right here next to me. And that's I just use that specifically for my latches on my track saw holder. 10 or 15 on them. And that's I have it loaded with the green. And that's all that does.

01:06:04

Speaker

is that just sits there and prints the prints the latches for me and then the the other printers like this is dinner twist latch. Well, yeah, but it's ah it's just a half moon for the track saw latch track saw holders the track holders. Oh, it's a it's a half holder. Yeah, I just I just actually got a new track saw and it came. It's my my original tracks don't have those holes. Oh, OK. But I'm talking the deal you mount the track on the wall with.

01:06:35

Speaker

Right? Right. Okay. buy I'll be buying. I'll be buying one or or four. ah so do Do you sell like a lot of those parts? Well, it's slowed down. I don't know in a printer working. Well, you know, just to to full disclosure is that ah here recently, like Etsy just died for me.

01:06:58

Speaker

Um, yeah, for a lot of people i've I haven't sold like last week was the first time that I really, I got like four orders. It was just like, I had, I sold some Milwaukee battery holders, DeWalt battery holders and tracks, all track holders. It was just like, boom, boom, boom, boom, boom. And then it's just, they're coming in and seeing it, but they're not buying. And I, you know, I kind of figured that probably with like,

01:07:26

Speaker

ah TikTok shop and Teemu, all those things, it's hard to compete. at the price points at some of them. And it's like, I'm not gonna lower my prices. It's just, if they buy them at what they buy them at, then they buy them. If they don't, they don't. Because I sell them in packages. Like, if you buy one set, it's this price. You buy two sets, you get a little discount. You buy three sets, you get more of a discount. Four sets, even more. You know, and like my battery holders,

01:08:01

Speaker

Um, and I gotta give a shout out to key Drennan from a black thorn. He actually we were sitting in a private hangout and he was like, you need to design something that's more compact where it's not just one battery on it. You need to do it with two batteries and you need to be able to hang it instead of hanging it mounting it to the wall flat. Why don't you bring it out where it's pointing out and you can stack more of them.

01:08:31

Speaker

And that's what I did. I took my design and I was like, why we were sitting there, I was too too measuring and I made it to where it'll mount on the wall with your batteries pointing out. And it takes a battery on top and bottom basically, or if you mount it sideways, but now you can stack them and it takes less square footage on the wall.

01:08:54

Speaker

And that was because he gave me the idea and then I went in and I designed it and and I made that for the Milwaukee and for the DeWalt and now the Festool. The Festool is not on my Etsy yet just because I just haven't had time to do it.

01:09:11

Speaker

Um, I've had people wanting it, but I just have one for you. at the time Get you a 3d printer and I'll send you the file. How about that? Hey, you know, you do speaking of sending files and then you're good on that too. I appreciate it. I still use my, uh, my star bond glue caddy. Oh, there you go. There you go. he's definitely final I cut it out on a laser box that he designed and all the little glue bottles and the, uh, what are you? Activators, activator and stuff.

01:09:41

Speaker

yeah I forgot about that. I have one out there too.

01:09:49

Speaker

Is there is there a significance to the red paint on everything? Is it just your favorite color? It's it's not ah it's not my favorite color, but it's part of my logo. And I wanted to kind of. I guess when you see that, you know, it's Steel Blade Woodworks, right? You know that that is.

Filming Setup and Techniques

01:10:12

Speaker

Yeah, yeah. Ladies and gentlemen, listening, I forgot that you can't see, but definitely go check out his Instagram and his YouTube and his entire all his shop cabinets are bright red.

01:10:24

Speaker

Yeah, that was kind of something I went with. That was kind of something I stuck with. Yeah. when i i was Back when I came up with Steel Blade Woodworks, I've been asked the question, how do he like I was sitting in this brand new shop over there through those doors and I was sitting there and I was like, what am I going to do? And i was I started staring at an old chop saw blade and I was sitting there and I grabbed it and I was like, well, let's just do steel blade woodworks. um When I came up with the name, um I had just mounted

01:11:00

Speaker

that big grizzly dust collector that I've joined. And I was like, well, I'm going to put steel blade woodworks on the top of it so it will look like a background when I'm shooting video. And then that's where the red started because I outlined it in red. And I said, well, now I got to keep red going throughout the shop. And that's.

01:11:24

Speaker

Sometimes that's what you gotta to do when you've got a shop that Spends a lot of time on camera. I mean there's there There's a lot of people that have shops that don't take cameras down there um You know, we we don't all film our projects I mean I'm we obviously do but I mean there's I'd say 90% of the people that have a workshop don't take pictures of anything and they don't care what their shit looks like. But I mean, for those of us who have a tendency towards filming in the shop, having a nice, nice backdrops and professional looking stuff just seems to be a

01:12:09

Speaker

It's the thing to do, you know? Well, I'm going to tell you, I'm bougie. When it comes to that, I'm just going to say it. I'm bougie. And one of my videos is I built a, ah I guess, kind of like a all my layout tool.

01:12:28

Speaker

that I have, i I took wall control and it's there's a video on my YouTube channel and it shows me installing, building that. ah There's kind of like two different videos, but one shows that I think it's 14 foot long countertop that I built out of out of ah wood.

01:12:49

Speaker

And of course it has the red cabinets. I took some Husky toolboxes and I basically made some skeleton cabinets and stuck them in. Cause it's something else I saw and, um, put all my layout tools on wall control with upper cabinets above it. And it has some real colorful lights on it too, but that was a filming background. So yeah when I film.

01:13:18

Speaker

I usually try to be that as my background. Um, and it, I, you know, I'm all about trying to organize and keep everything. I'm kind of one of those, if you put it in a drawer, you're probably never going to use it or you'll forget about it. And when it's out there in the open, you're like, Oh yeah, I do have that. Let me go grab that. So like all my layout tools are all hung behind me on wall control and.

01:13:46

Speaker

I mean, it's just, i I'm a, when it comes to layout tools, I am a sucker. If I go to Woodcraft or Rockler, I'll go through that aisle. And if it's something I don't have, I'm, it's coming home with me. You know, I just, are you telling me that your rulers and your squares match your cabinets?

01:14:06

Speaker

well there yeah yeah There's some on there. right yeah Yeah, yeah. What do you, as far as, since we're electronics and digital digital and stuff, what what do you film with? Do you film with a phone? Do you film with a? No. Some of the like Instagram stuff, yes, is on a phone, but right behind me, ah I have a Canon M50.

01:14:47

Speaker

um yeah it's got a swivel full rotary type wireless it it moves that camera everywhere. oh So if um is that on top of the stand? Yes. That's in between the camera and the stand? Yes, sir. Yeah. um It's a nice setup. Does it follow you? You have to move it. You have to move it. Okay. With the wireless control. But but it's But a remote control and a monitor is just a beautiful combination. If you step a couple steps over, you can see, you can push the button and track it over. And that is that is the one thing that is just so much better than and you know my half-assed setup, which is I'm using my my last Android phone as my shop recorder. you know i just you know I just use my old phone.

01:15:42

Speaker

and stick it on a mount, but I can't see what I'm doing and I can't see that. It's like I if I want to do something where my face is actually on camera, I have to set up the camera, I have to point it where I think my face is going to be. I have to hit record, I have to walk in front of it and smile at the camera, wave and go.

01:16:08

Speaker

aim test, turn around, walk back to the other side of the phone, stop the recording, hit the playback and see if my face was actually on camera or not. Before I want to actually start trying to do anything in front of the camera, I have to go back and replay the footage to see if I was actually on camera or not. And because I've recorded a few minutes of FaceTime footage that didn't show the top of my head. And you know not good and ne now I test every time before I... So that monitor and the remote must be a beautiful thing to have. Best best money I ever spent. um the The road mic is a directional mic and

01:16:53

Speaker

Um, I, I'm a big guy. So using a lavalier mic, it sounds like I'm freaking having, I just ran a marathon because it catches every freaking breath. Like, and it's horror horrible, horrible. And, um,

01:17:11

Speaker

I went with that mic. I tried it on a whim. I was like, I asked him, I did ask questions to some people and I ended up buying that mic and that thing is a very dang good mic. Um, the quality is good because when they get, they will forgive you for video, but they will not forgive you for audio.

01:17:37

Speaker

If your audio and I'm not, that's not the best audio. I know that there's probably better stuff out there for myself. That works good. Um, I talk loud enough. I'm not a soft spoken person. So everything does come across. Uh, the sound is there. It's just, I need to learn how to talk sometime because I get mumbled, you know, but, um, for, for B roll.

01:18:05

Speaker

For B-roll, I use this Canon camera. It's a basically like you're just a camcorder, but it's a vixia, whatever it is. I can give you all the numbers. But I usually set that up on the side, and that gets me my B-roll. If I'm building something, like or if I'm putting like a ah tool together or something that's usually capturing the B roll that I'm. But it's you know, I'm still learning. I'm still trying to figure out the stuff. Camera position. What do you what do you edit with? I use a software called. Oh, you had to ask me.

01:18:54

Speaker

it's a

01:18:57

Speaker

Sorry. I'll think it's something you've been using a long time. Yes. Yes. And Jake and them tried to get me to change over to the one they use. And I was like, nope no, no, I'm not going to do it. I already learned how to use this. i'm I'm familiar with it and it doesn't take long. Oh, what's it called? I don't want to move the screen because I don't want to mess nothing up. It's on this computer.

01:19:23

Speaker

um but yeah da vincan no, no, no, no, no, no. um This is. Adobe based.

01:19:35

Speaker

Sony. No, it's something 360. I'll I'll think of it in a little bit. I'm sure there's a hundred. Yeah. Yeah.

01:19:46

Speaker

But you know, the thing about software, if if you're using some old outdated software for your 3D modeling and your video editing, and they don't have all the fancy features, and they don't have all the neat bell bells and whistles, and they're not guaranteed to make you fantastic looking video every time, but you're proficient in those,

01:20:15

Speaker

You're better off using the old shit that you actually know how to work than you are to jump into something big and complicated and messy and you're just going to be sitting there for hours fighting with shit and you're never going to get anything made. So there's something to be said with sticking with the old software.

01:20:35

Speaker

I mean, I've got a video editor that's a paint shop. It's like paint shop pro version five. I think I got it somewhere about 18, 20 years ago from somewhere and.

01:20:52

Speaker

I still use it for some basic image editing features. I mean, if I just want to crack open a ah JPEG and crop it, you know, if I want to crop it or chop off the sides or shrink the size or whatever.

01:21:09

Speaker

It's a piece of junk software, but I'll be damned if I can do all the basic image editing functions. I mean, it's not going to do, and it's not going to auto outline my shit for me. It's not going to auto trace shaped. It's not going to do any of that shit, but it's going to resize crop and change formats. And I, and I can do it in about six seconds because I've been using the damn software for 20 years. Now does the software suck?

01:21:37

Speaker

mean Well, no, but I mean, it's 20 years out of date, and it doesn't do all the na of the fancy new shit. But it works. It's really easy. And I really know it. And if I don't need any any of the advanced features, you're better off to use the old shit that you really understand how to work it than you are to ah mess with some newfangled crap.

01:22:01

Speaker

yeah it's it's right back to the sanders you know if you don't need all those functions then get the the the the less the better priced one for your need or your 3d software you know you're not going to learn fusion 360 because you don't need the other 78 000 buttons yeah well On one hand, you don't need to buy beat the the software that has features you don't need. But on the other hand, if he has a couple of friends that are trying to get him to jump into the software package they're using, then that goes back to something that I believe you said last episode when you're talking about the, I think it was a neighbor kid got a CNC, you said,

01:22:48

Speaker

what software to use? Well, you go to better go buy Vectric or I'm not going to tell you how to use your CNC because if you don't use what I'm using, you're not going to get my support. so Wow, it wasn't that harsh, but yes. i mean You're going to be limited ability to provide support unless he does the things the same way you're doing.

01:23:13

Speaker

So as long as Joey's fine doing what he's doing with the old software on his own, he's fine. But if he wants support and he wants the help of his friends, he's going to have to jump ship and learn what they're doing. So it's all about whether you need anything better or whether you're just happy where you are, really.

01:23:36

Speaker

Right. Right. Especially the way things are upgrading. And yeah these days, these days you can't even buy software. you can you can rent software for a little while but the software that that that old shitty software that you've had for 15 years and you're comfortable with you paid for that shit you own it you get to keep it it may not update but it already does what you want and you don't have to pay for it every year so that's also something to be said for sticking with the old stuff yeah and speaking of update Jesus

01:24:13

Speaker

What's going on with Lightburn? We seem to have to update every time we open it. Here's the last few weeks. You know, I don't open Lightburn enough to notice. And I also don't update because I bought Lightburn once. I bought a year's worth of Lightburn about three years ago when I got the laser. And so about two years ago, the software expired. Now, when Lightburn expires, it doesn't just shut that shit down. What it does is it cuts off your ability to get the support and it cuts off the ability to download

01:24:57

Speaker

the paid versions of the updates. So I'm still using the version of light burn that I downloaded, you know, for your well,

01:25:09

Speaker

Well, no, I mean, cause I let it update over the year that I had, oh you know, the paid ownership of it. So maybe two years ago, I got cut off from the updates and I'm comfortable using it the way it is because I use it about twice a year. And I don't feel like paying for it again. If I don't really need anything.

01:25:29

Speaker

Yeah. I, unfortunately, when I bought the fiber, I had to buy a, uh, an add-on so I could run the fiber and the CO2 out of it. So you got to kind of keep everything up to date or those machines. Yeah. Well, see, yeah, you needed the fancy features. You had to buy it again. Yeah. Yeah. What fiber laser did you get? Is it, is to 360? For what? What's that? I'm sorry. I said, what fiber laser did you get?

01:25:58

Speaker

Um, I got the Aurora, uh, 50 watt, the Aurora eight thunder. Oh, nice. Yeah. With the, it's a, and the reason we got a grant. So thankfully, you know, $10,000 laser. That's crazy. But the reason I wanted to get that one is it comes completely encased. It has its own internal exhaust fan, its own lighting, its own safety shield, where the, the, the,

01:26:29

Speaker

Well, I won't say that's not a Chinese one. The ones you buy on online that are just open gantry, like there's just. Right.

Safety and Unique Tools

01:26:38

Speaker

People are going to be people are going to be blind because they they don't understand that they're staring at a welder. you know ah Basically. Well, yeah, just ah just a reflection off of that. Right. Just by looking at the direction that burned your eyes.

01:26:52

Speaker

Totally. yeah I don't even, I get, I get headaches looking at it through the green glass, through the shielding glass. It's like, I can't watch it for very long. I can look in and see that it's doing what it should be doing. But, and the other thing, few extractions.

01:27:06

Speaker

Are you telling me that those $7 green glasses that I bought off of Amazon are not going to be sufficient? They are not for any length of time, no. ah i I don't look at my four and a half watt diode for more than 30 seconds at a time with those pieces of crap. ah yeah that Normally i I'll start a cut, I'll engrave whatever I'm doing, I'll start something and I'll eyeball that stuff for the first, you know,

01:27:36

Speaker

10, 20 seconds just to make sure everything is moving and everything's going right. and It looks like it's not going to start a fire. And then I'm literally going to dip around the corner into the other half of my basement where it's not even in my peripheral. And I'll just, you know, take the special glasses off and look at my phone until it sounds like something going quiet in the other room.

01:27:59

Speaker

Yeah, because it is very easy to just like you don't realize that you're just going to look over at it. Right. Yeah, I just leave the room. So I think we should jump on to some of our other things here. Speaking of things. And did Joey, did you bring a thing of the week? ah I saw something I didn't bring anything, but I saw a tool that I thought was pretty cool.

01:28:28

Speaker

And that's enough. Tell us about it. It's called it's an Atlas track. So it was brought to my attention actually today. And I thought it was very unique. The track actually rolls up. Inside the sustainer with the song. And it's out of a kind of like a sheet. I wouldn't say sheet metal, but it's like a stainless steel track that will roll up into a roll.

01:28:57

Speaker

And then when you get to your job site, you take it out and it straightens out. It unrolls and it's kind of like spring steel and it unrolls in the, the, the saw mounts directly onto it. And it's a track saw. Is it, uh, does it get, uh, yeah. Like stiff. Yeah. Yeah. Real stiff. Al.

01:29:23

Speaker

instantly

01:29:28

Speaker

And just the thought of that track saw is getting out a little on the fifth side, too. I guess I stepped into that one, didn't I? Yeah, you did. With both feet. We're all here because we get a little stiff for tools. So it's OK. We'll forgive you. We understand. You're amongst friends. We get it. Hey, I'm very comfortable with myself.

01:29:56

Speaker

Yep. So what, what was the name of that guy again? Atlas. atlas atlas Yeah. Atlas tracks off. e Okay. That sounds like a good thing of the week. Uh, what do you got, Al? I actually have a person. It's an Instagram channel, but, uh, has this person has turned into a very good friend. Her name is Annie van Orman. Uh, and her channel is Annie's lower underscore VW.

01:30:23

Speaker

And I found her because I'm a Volkswagen person. And what Annie has done over the last two years is completely ah take apart a 1969 VW and restore every nut, bolt, seam, wire clip. She rebuilt the blinker on, you know, I mean, it's she just did this. It's.

01:30:45

Speaker