Become a Creator today!Start creating today - Share your story with the world!

Start for free

00:00:00

00:00:01

16 It's a wrap!

In this, our final episode, Al and Jeff talk about what we’ve been printing. Al is already over 2000 hours on his A1, and Jeff has been burning prints and making suncatchers.

Things of the week:

Al: The Fantastic Maker Community

Jeff: AirWeights cnc vacuum panels https://airweights.com/

Eazao pottery printer https://www.eazao.com/

Patreon: Discontinued

Discord: https://discord.gg/hHp8Sv7vt4

Recommended

Transcript

Introduction by Jeff and Al

00:00:12

Speaker

damn Hello and welcome to Digifabricators, the show where we learn how makers and artists use their computer-driven tools for fun, art, and profit.

00:00:24

Speaker

I'm your host, Jeff Stein, a.k.a. a Weird Guy, and with me is my talented but humble co-host, Al Schultz of New York Woodworks. How are you doing today, Al?

00:00:35

Speaker

I'm doing wonderful. Good afternoon, Jeff. I'm doing pretty good, too. Let's ah jump straight to this. disclaimer, we don't have a whole lot of time today, so let's throw this out here. um Even though we pretend to be experts on the internet, I would like to point out that neither of us have any actual training and are just guys winging it in our shops and learning as we go.

00:01:02

Speaker

All advice provided is based on our personal experience and possibly inaccurate assumptions, and it's worth exactly what you pay for it. If listening to this show causes you to take out a loan to buy new and expensive digital tools, you may tell your spouse that it was our fault, but do so at your own risk.

Why End the Podcast?

00:01:23

Speaker

Okay. So i think, i you know, I think the big monster in the corner that's lurking at us is that I think this is probably going to be our last episode.

00:01:38

Speaker

Yeah. We're, running into problems with timing, we're running into problems with motivation and we're running into problems with the subscription model running out for us.

00:01:53

Speaker

Um, I mean, it's a couple hundred dollars for the Zencaster plan. Uh, and we've we've got another week or two before the year's up.

00:02:06

Speaker

And, uh, I just, you know, we're, <unk>re we're wrapping up our year and we're just recording episode 16. And so we've clearly missed the mark of biweekly by a large margin.

00:02:21

Speaker

Yeah. And I just, it's, it's gotten increasingly more difficult to find the motivation to push this as a priority in our lives.

00:02:35

Speaker

Yeah. And it was an experiment to start. And we, now we know, what goes into it. So if we decide to come back to it, we have a better understanding of the dedication you have to put into

The Effort Behind Podcasting

00:02:49

Speaker

it. for those of you thinking about podcasting, it's a great and fun thing, but it is way more than you think it's going to be. ah love it That's been my experience.

00:03:01

Speaker

It's a lot. It's, it's, I mean, I don't know about a number, but I would say, what you're hearing is 15, 20% of the effort and the time invested.

00:03:12

Speaker

And I'm not even editing, you know, right. Even investing more time. And that's not a poor us in any way. It's just a, Oh, I have a new respect for people that do this and can pull it off successfully.

00:03:27

Speaker

Yeah. That's that there. There is a lot that goes on with it. And a lot of the major hassle, I mean, I was counting on the recording time doing what the recording time does. i was counting on the editing time, but i wasn't counting on how many hours it would take me to try to find people and try to work a schedule and a time that actually works for three individual people who are doing lots of things in their lives the same time.

00:04:00

Speaker

yeah That was, I, you know, i thought, I would just reach out and, you know, ask a bunch of people if they want to do the podcast. And ah you know, you expect it, a certain percentage of yeses to come back.

00:04:19

Speaker

And then once you've got some yeses, you just go all sit down and you record the damned thing, but damn, it just doesn't seem to work out that easily for me. I don't know.

00:04:30

Speaker

but it was sound like, ah but it's a, it's a new respect for, you know, I mean, I haven't been a guest on many podcasts, but now I'm like, Oh wow. They were really, it wasn't just me showing up, you know, there's a lot of other stuff going on to your, to your point, you know, the, the amount of time that, you know, you basically have to have conversations with people before you have a conversation with the people.

00:04:53

Speaker

yeah Right. So it's, it's a, it's a thing, you know, and, but anyway, we're going to do a regular show though, right? You've got something. Yeah. Yeah. Yeah.

00:05:04

Speaker

Um, I'm going dedicate us ah you know a 10-minute block at the end of the show here to but do do a bit of a wrap here.

Al's 3D Printing Journey

00:05:14

Speaker

But in the meantime, I'd like to put on something a little bit more entertaining and talk about what we've been doing for the last, what is it, six or eight weeks since we actually published the last episode.

00:05:28

Speaker

um You've been doing so much printing. Yeah.

00:05:34

Speaker

It's just, you've gone from, i don't know what a printer is. I don't know how a printer works. It's just one of those magic things where you just point at something on the internet and it just pops out on your printer. And I don't know anything about it too.

00:05:50

Speaker

Holy shit. Are you printing everything now? I am printing everything. I do blame this as as our as our intro says, you know you can blame you know buying digital equipment on us if you want to. And I blame Jeff 100%.

00:06:07

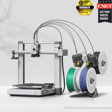

Speaker

one hundred percent For forced have me to take that forced me into the 3d printing world. Um, I got on a ah bamboo, a one combo, so not the smallest bamboo, but the, the, the, the entry level open bed slinger, you know, classic, uh, printer, a bamboo printer. And it's amazing. I love it. I absolutely love it.

00:06:31

Speaker

Um, if I had room, I'd have five a ones running. I do like the looks of the enclosed printers, the P1S, P2S, the X1s now. um But I've been...

00:06:44

Speaker

Like I said, I got it in July when they were on sale. And yes, as of yesterday, I had a little over 2000 print hours on that thing already in four months. It pretty much runs.

00:06:56

Speaker

My wife has asked numerous times, do you need to let that thing rest? And I'm like, no, keep showing plastic in it. No, no. You just keep feeding that damn thing plastic and it will just keep trucking.

00:07:08

Speaker

Yeah. And I, I went from the immediate, you know, ah click click the flexxi you know click and print flexis and dragons and eggs, of course, and all that. And they were fun, and I still do them. But now I'm... Hueforge has become a big part of my life. I'm doing a lot of artwork and have some projects ah with Hueforge, which

Bamboo Printers and Ecosystem

00:07:30

Speaker

is the... Amazing stuff.

00:07:32

Speaker

It's so beautiful. So beautiful. um You can check all that stuff out over on my Instagram. which Jeff will tell you later. And ah the other one that I'm really excited about is getting into pieces and the, oh my God, what's his name? Dad, the guy that did the seven foot robot.

00:07:51

Speaker

He was like, oh my gosh. Jacob. Yeah. He really inspired me and I've actually, it's already printed. It's not now. i Actually dad crafted Grant did it too.

00:08:02

Speaker

yeah They both had seven foot robots. Okay. Dad crafted does the comic book corners. Yes. Yes. yeah And they both have seven foot robots. Yeah.

00:08:13

Speaker

Yeah. um He kind of inspired me to go large, you know, because I was limiting myself to the little bamboo, you know, plate. And I have a 44 inch nutcracker printed.

00:08:27

Speaker

It took me 90 hours of print time. And those big projects are a commitment, then aren't they? Yeah. So I'm excited about, uh, I get my wife a nutcracker every year since we've been married. So this is going to be the big, you know, this is a big one for her.

00:08:43

Speaker

And, uh, so I'm looking forward to getting that finished. So yeah, it's a, it's a world, man. Let me tell you. And it's. Now, did you find that or did you cut that yourself?

00:08:54

Speaker

I found it. I found it. I will say i'm not ah I'm not modifying a lot or doing any major designing. I'm using the Bamboo Handy and Bamboo or Maker World you know pre-made models.

00:09:07

Speaker

okay you know Lots of people are asking me, oh, give me tips and tricks. And I'm like, point and click? ah Point and click with ah with ah a database and a machine that are thoroughly connected. and It's just amazing. like there's a significant difference between what you get from maker world, especially as a bamboo user and what you get from say thing of ours, because if you go to, you know, thing of ours or things or thangs or one of the other 846,000 sites out there that have models on them, all those other sites, all those other sites have the 3d model.

00:09:52

Speaker

You can download the 3D model and you need to import that into your slicer and you need to do supports. If it needs it, you need them in this area. You need them in that area. You need these settings to make it work. You need those settings to make this not screw up.

00:10:09

Speaker

And you have to do all of that stuff right out the gate to get anything to work. But the difference is with the, the, the the maker world and bamboo is the fact that they will host not just like the STL model, but they've got the sliced pre sliced file that he already has so the the person who makes the model puts it into the slicer, adds the supports where it needs it, changes the settings to tweak it to make this model print properly.

00:10:49

Speaker

on a bamboo printer. And then you basically save the project with the slicer and you're sharing the project file pre sliced, not the yeah model itself. So when you it, it really can be out the gate a point and click because you can point and say, i like this model and without touching any settings, any software, you can just use your phone and pull it from the server and send it straight to your printer and not have to know a damned thing.

00:11:27

Speaker

95% of my printing comes from my phone. And and I got to say, I've got a couple of friends who are on other brands of printers. you know And they like doing the research and figuring out what bed temperature and what speed and what viscosity and all that. you know i don't i don't That's not me. i don't want to I don't want to mess with that stuff. like It takes so much stress. Bamboo takes so much stress out of the process.

00:11:52

Speaker

Now, if you like doing that stuff, like you're a person who... you don't want to, you're not a point and click guy. You're like, okay, I point and clicked once now, what can I do with it? like You know, so that's a different, I'll admit I spent, I spent a few months doing point and click. I mean, I didn't spend as much time on the mobile, but I, you know, I generally use my mobile to browse the database for models that I want to download to my laptop and use later.

00:12:23

Speaker

Um, But I mean, when I started, i would, you know, download it open it in studio and basically make sure the scale is where I wanted it and the colors were what I wanted and I'd send it on over.

00:12:45

Speaker

And then the more time I've spent printing and I think I'm, uh, I'm well over 5,000. you know, maybe 5,500 plus or minus some hours on this machine in the last year.

00:12:58

Speaker

But the the longer I go, the more i don't just leave all the settings that the creator put in there. Yeah. I look at this and I go, oh, i don't need to adjust these things because my printer works fine without all that crap. I mean, there's, there's a lot of models that'll have like custom speeds.

00:13:21

Speaker

where they'll, they'll say, Oh yeah, I think you should run this a little extra slow, or this can go a little faster. And a lot of, I mean, my printer works on its defaults so damned well that I'll, I'll go, you know, I'll open a project in studio and I'll like, Oh, I don't need to adjust this shit. And I'll just hit the clear button on all of those settings back to defaults because I know it's going to work fine for me on defaults.

00:13:47

Speaker

Yeah. And then you know, it's, gotten to the point where you know when they've got it in this ecosystem where you download the stuff you print the stuff and then they try to recommend you go back and rate their print profile i've gotten to the point where i don't really feel comfortable writing the print profile because i almost never print it with the settings that they gave me and I've got to the point where I'll go in and go, Nope, I want to switch this on and I want to turn these things off that you thought was a good idea. And I, and now it's to the point where i the people that uploaded this may not know what they're doing. And I might think I know better than them and I'll start flipping

3D Printing Failures and Tips

00:14:33

Speaker

the switches before I ever print it.

00:14:35

Speaker

So it's like, I don't know that I can rate the print profile because I didn't use it Yeah, yeah without without writing a ah but you know paragraph and who's got time for that. and Right, exactly. It's like, yeah, well, you know, the print profile was good, but I changed all these seven settings that I didn't think were appropriate. And it's like, well, you know, i'm I patting you on the back or shitting on you for using settings I didn't like? and it' You know?

00:15:03

Speaker

I don't rate things as much anymore, but. So let me ask you a question printing wise, not even getting into quality and all that. And again, we use the same brand of printers. Yours is a ah the Ferrari version, mine is the Pinto version.

00:15:18

Speaker

But um when, what do you think in an honest, you know, I know you, you like to tweak things and touch things, but in an honest, what is a ah normal or expected failure rate?

00:15:31

Speaker

Because I get a lot of, again, I have a friend who's trying to make like an old Ender, you know, Ender 2 that he bought at a yard sale for $10, you know, and he's just like, just figuring it out. And he's like, man, I'm failing like eight out of 10 prints. And I'm like, well, number one, it's the printer. You know, that printer is technologically a paperweight. There's a lot of bed leveling and manual tweaking to get those things to work right.

00:16:00

Speaker

And I mean, I've, I've known lots of people that owned a lot of those printers and once you get them leveled and locked in and set up, you have a failure rate that drops right through the floor up to bamboo quality, but you have to know how to do all the leveling and you have to get it all perfect for that to happen.

00:16:23

Speaker

Yeah. Yeah. That's why I like having the LIDAR and the auto leveling set. Now I don't have LIDAR in mind and that my model is, does have the auto leveling, but I would, I would say other than dirty plates, I'm less than 1% failure rates, unless it's just a model.

00:16:44

Speaker

I've had a couple of models that it's like, I just tried to print one the other day. It was a really small piece and it just would not, nothing I changed would, it was just a bad model, you know, and I'm not shitting on anybody's design. I didn't design it, but it was like,

00:16:59

Speaker

finally after four five times i was like okay this obviously isn't gonna work and i just threw the the other half of it away and that's just not something i'm gonna print correct but moved on yeah i've i've scrapped a couple projects it just didn't seem to want to go but um yeah my failure rate is much much more centered around you know the the the part falling off the plate because yeah dirty yeah operator error, the part fell off the plate. That's, that's a massive, massive, wild share of it.

00:17:37

Speaker

You know, 90, 95% my failures, your operator error and part fell off the bed. um It wasn't clean. I didn't use enough glue. Whatever. you know um so So in 3D printing, it's just like the rest of the digital world?

00:17:55

Speaker

the the The filament roll got fucking tangled or some shit. You know you're run into something like that every once in a while. Hardware glitch somewhere along the line fills up 5 or 10% of the errors. But for the most part, yeah. i just I don't have problems like 80% failure because because of the fact that our beds are perfectly level yeah at all times.

00:18:24

Speaker

And it if they get it, you can adjust them manually, but you have to like jump into it and really dig in. I've never needed to look at it.

00:18:36

Speaker

Yeah. I've never even changed the temperature. on a bed or, or a hot end, or I've never, I've never changed the parameter at all. I'm printing out of the box 2000 hours.

00:18:46

Speaker

and Most of my temperatures are normal. Um, if I'm doing a print without glue and I'm worried about whether it may or may not fall off the bed,

00:18:58

Speaker

I will bump the bed temperature up by five or 10 degrees Celsius because having the bed hotter makes the part stick to it a little bit better.

00:19:12

Speaker

um So every once in a while, that's a tweak that does see those as as the the more you go the more things you learn that normally you just download something and you hit print, but when it doesn't work,

00:19:26

Speaker

then you start thinking about what things I can tweak that would make it work better. And one of those tweaks is that you can bump up the bed temperature.

00:19:38

Speaker

And the, the other one that was a huge win for me, not going to be relevant to you at all, but having the enclosed chamber, it generally doesn't have as big of a problem with say corner warping,

00:19:56

Speaker

You know, where if you've got a big wide part, the corners tend to peel up as they cool off. It'll shrink on the top level and it'll pull the corner off the bed. Yep.

00:20:07

Speaker

And then you're driving the nozzle through the part when it comes back around. had a big problem with that, with especially Hueforge pictures for the longest time.

00:20:19

Speaker

And i at some point did some research. I figured out that the, the, the X one has got a fan on the side and it's got a little air scoop that sucks the air from the bottom up and then blows it out at the height.

00:20:38

Speaker

It's just like right at nozzle height. So it's helping cool off the part. As soon as it comes off the nozzle. which is really awesome if you're doing things that involve bridging where you're where you're you're running a string across and there's nothing underneath it. you just you know It's just an unsuspended string that goes across.

00:21:03

Speaker

um That's really good because you want that to cool off before it starts to sag. Right. But if you've got a big wide part like a hue forge and you've got a fan blowing on the side of it, that side's going to fucking curl and it's going to do it consistently.

00:21:22

Speaker

And it's going to piss you off until you realize that if you go into when when you're in studio and you've got the filaments set over on the left side and you get the filaments set to be, you know, generic PLA or bamboo PLA or whatever.

00:21:38

Speaker

If you edit that print, the the filament profile, you can go over to the cooling and scroll all the way down to the bottom. And there's a spot for auxiliary fan, which for PLA defaults to like 70%, I think.

00:21:54

Speaker

I just turned that fucker to zero and hit close. And then it runs my entire print without using that fan that blows on the side of the print bed.

00:22:09

Speaker

Now does that default back when on the next print? Yeah. Yeah. Okay. Okay. I mean, there's, you can, you can save that as a preset. So instead of choosing from the dropdown, you can say, well, that's bamboo PLA or that's generic PLA.

00:22:28

Speaker

You can go on the same dropdown menu. There's a line that says custom and you can click on the setting that says, PLA, no fan that I've set because you can, you can just edit one and then you can up at the top, I think there's a save button and you can save that as a custom filament profile.

00:22:49

Speaker

Nice. So I've got a custom profile that says PLA, no fan. So I can just hit brand custom PLA, no fan. And it's the, the, the generic PLA profile with the auxiliary fan turned off.

00:23:07

Speaker

Right. And now the back left corner of my parts don't fucking curl up all the time. Yeah. And I'll be damned if I, I, I mean, if I've got a big, if I've got like a tall, chunky part, it's not a problem and I don't worry about it.

00:23:25

Speaker

the The problem is when you've got ah bunch of thin layers that cover a large portion of the plate that makes the plate staying level with the fan for a long time.

00:23:42

Speaker

Because I mean, if you've got a tall, narrow part, by the time the fan has started to cool things off, the fan is pointing at a half inch up the plate or an inch up the plate versus a hue forge kind of thing is a wide, thin piece. And it still takes, you know, three to six hours to print one of these things.

00:24:05

Speaker

and the entire six hours it's the the plate is all the way at the top because you've only, you only put three millimeters on the plate and the fans blowing in the same spot and it's cooled off the part and it curls up.

00:24:20

Speaker

And, you know, so, I mean, the longer you print, the more you realize which settings you can change to avoid the problems that the defaults is giving you.

00:24:34

Speaker

So, That's that's your, your just about the plumbing. Cause I think I, I changed very little in the first three or four months.

Painting Techniques for 3D Prints

00:24:45

Speaker

i yeah I ran mostly defaults and then it's just, you start to hit the point where this model's not working. What can I go in and which check boxes are going to make this fucking thing actually come out in one piece the way I want it.

00:25:02

Speaker

Yeah. And, the The more you run into those problems, the more checkboxes you actually start to understand what the hell they do and how they work and when you want to go ahead. And I mean, sometimes you'll download a model and you'll look at it and You're going to go, okay.

00:25:21

Speaker

I've seen a part like this where these particular features are going to give me a problem and I'm going to go ahead and tweak those settings now. Yeah. It's like anytime I print something flat, I know i want to turn off that fucking fan yeah yeah back or it's going to fuck with me. You know, I mean, it's just one of those, you know, it's a wide thin part. I want to put the fan off.

00:25:45

Speaker

um So are you're going to paint your nutcracker by hand, right? Yeah, I'm actually getting an airbrush. Oh, there you go. but we're gonna I'm going to prime it. um I've gone through some forum stuff and everybody suggests priming it and then painting it.

00:26:04

Speaker

And then I'm going to airbrush it on top of that. I'm going rattle can the the bigger parts where I... write Right, right. Rattle can the primer, rattle can your base coat.

00:26:15

Speaker

And then, yeah. And, you know, you know, that gets into the areas of paint that I just don't work very well with is, you know, okay.

00:26:28

Speaker

I can take something and I can, yeah you know, when you like color by number kind of things, you know, where everything in this area is yellow and everything in this area is red and everything in this area is green. I can paint like that.

00:26:45

Speaker

yeah But the, the, the, the part of painting that I'm not good at is the part where I realized that if I put a layer of black down as the base coat, and then I put my green and my red over it, it'll look completely different than if I put a white base coat underneath,

00:27:07

Speaker

to layer shit. That's the level of painting I've never really clicked with. And also the parts that really get me is the shadows and the highlights and all that shit to make where it really starts to look good yeah is adding the base coat. So it adjusts what, I mean, cause red looks different if there's black underneath it or white underneath It it really changes the way the red pops.

00:27:39

Speaker

And then the shadows and the highlights, i just I just can't wrap my head around that level of painting. I'm really good at, I can take everything in this area and paint it blue.

00:27:53

Speaker

yeah i'm I can do that, but I don't like it, which is why i didn't buy a printer until they had a reliable AMS system for me to use.

00:28:07

Speaker

I will spend two hours painting a model in studio and then let it run for 18 hours with 214 color switches just so I don't have to paint the fucking thing by hand.

00:28:26

Speaker

And because that because that that becomes a technological challenge for me, which is fun versus a physical painting challenge for me, which is not Yeah.

00:28:39

Speaker

I'm, and I'm just the opposite. i'm I'm looking around. I must look like a maniac, but I'm looking around to see if there's anything in here, which there isn't. But, uh, I was an art major in school. I i painted for several years.

00:28:52

Speaker

Um, and I am always like, how can I change this from, a solid palette? This is this color. This is this color. How do I shadow it? How do I shade it? How do i you know, I actually enjoy that. I'm really looking forward to I used, ah I used an airbrush a hundred years ago.

00:29:11

Speaker

and I'm really looking forward to getting back into that just for, for detail, for shadowing and, uh, you can cover a lot with, with, uh, with paint.

00:29:23

Speaker

A lot of paint. ah I've actually got an airbrush. I haven't used it in 20 years because I couldn't figure out how to get the damn paint the right thickness. And every time I turn it on and hit go, it would just plug up in the first 20 seconds.

00:29:37

Speaker

And I eventually just got frustrated and threw it in the freaking corner and left it in the box where it's been sitting for 20 years. Yeah. You just patiently waited until you could go into bamboo studio and paint with your AMS. Yes, exactly. But I still have one. Should I ever choose to learn how to use it?

00:29:55

Speaker

There you go. Ah, So have you been printing anything else? Let's see. You got a lot of Hueforge. Hueforge is just this last week. um I've done a lot of ah shop stuff like brackets, hammer holders, you know screwdriver holders, hose reels. Festool has a bunch of um ah you know hacks and fixes and stuff like that.

00:30:24

Speaker

I got oh yeah storaged the little storage boxes, the Gridfinity boxes. yeah I've printed... i don't know if you can see them back here. there's a There you go. There's a whole stack of them right there. yeah which are Which I'm going to laser. I have ah scrap acrylic from Years ago, we had this crazy thing called COVID going on. Yeah.

00:30:49

Speaker

And so I CNC cut thousands, I feel like, of sneeze guards for a company. Okay. um So i you know you end up with like eight foot eight for long, but 12 inch wide strip of quarter inch acrylic. So I've got scraps. Yeah.

00:31:08

Speaker

right so i'm gonna cut ah on the laser with uh with a box creator i'm gonna cut an acrylic rack that these boxes will slide into you know make them basically make them like a drawer or a cabinet and uh and they'll look it's scrap but it they'll look cool with you know right you know kind of thing um I just got a new, new to me CNC, a small Laguna two foot by three foot machine.

00:31:40

Speaker

And, uh, so I'm printing, the theme for her is Alice, uh, you know, from the, uh, Resident Evil franchise. So I've, I've printed a couple of like, uh, you know, umbrella court badges to go on it and the things like that.

00:31:57

Speaker

Um, watch Lots of Halloween stuff. You know, again, there's the whole, what can you legally or morally sell? So I don't really advertise a lot.

00:32:08

Speaker

I kind of look at it as, yeah, I can't sell you this model, but if you want to pay me for the material to print it, I'm happy to do that for you. Right. It's, it's, well, I mean, it, there's a line where suddenly it does it become a favor for a friend or family.

00:32:28

Speaker

versus yeah. Well, the, and I mean, there's a, there's a spot where it's probably not okay to put the stuff in a store or a flea market or a craft sale.

00:32:42

Speaker

And, and then there's a much, much stronger, darker line that says you don't put that shit on Etsy because don't have the rights to it.

00:32:53

Speaker

And you're shitting on somebody else's business at that point. Right. Um, Whereas, i mean if I mean, it's a little bit of but more of a gray zone if you're hitting a flea market or a local store where a couple of local people are going to see it and they never would ever, ever found this shit on the internet where nobody else has got it for sale even, you know, maybe.

00:33:20

Speaker

yeah Yeah. like when i're goingnna Put it on Etsy, you're definitely into the black side of the... yeah There's a harder line there. And i'm I'm not looking to do that. We're going to, my cousin, ah this is ah not a timestamp thing, but my back has been messed up for like the last three, almost four weeks now.

00:33:40

Speaker

And my cousin comes down and helps me like move some stuff around one or two days a week sometime, you know, for an hour here, hour there, or whatever. And so I've been printing a lot of stuff for him. he like He's like dumbfounded by the capability of this thing. Like he wanted something he to hold his watches. He's got a watch collection. So I printed them. I got on bamboo handy and searched watch stand and found one. He was like, oh my God, it's amazing. You know, so I printed him one of them.

00:34:06

Speaker

uh another thing i've printed a lot of is a lot of 2a stuff a lot of ammo boxes like right they're really handy i mean they stack nice they're clean they're dry they're you know i mean they're not like ammo cans take out the field these are like on a shelf kind of thing but they're really cool So you know that kind of stuff I've been printing. Another thing we're doing or I'm doing is um and know you can't see it, but there's a I'm showing him a picture. It's a 3D printed snowman in white and a 3D printed ah Christmas ornament.

00:34:44

Speaker

So rather than sell somebody's product, what we're doing is my sister-in-law ah owns a farm store. like a home It's called Homesteaders. And we're going to do a paint and sip kind of thing.

00:34:58

Speaker

on but I'm just going to print a bunch of these ornaments in white, shoot them with white primer, take some acrylic markers and acrylic paint, and we're just going to go down. And for $25, you can have ah you know a cookie, and a glass of wine, and ah and take an ornament. You paint it all.

00:35:14

Speaker

kind of thing. Right. Um, so it's not, again, I'm not selling you the ornament, but I am selling you the experience on the ornaments in it. Right now, you know, see that that's on the lighter side of the gray zone yeah you know where you're not really quite selling them. This is a product that's part of an experience that comes free with the paint and the line. Yeah. Again, back its it's a, what do you what do you call that? uh,

00:35:43

Speaker

ah not a consolation but a loophole no no no like oh no no no like You know, when you're you show up and you get a trophy, you know. Yeah, participation trophy.

00:35:56

Speaker

Yeah, participation trophy. Thanks for showing up. Yeah. I'm giving you this. You're paying her for the, you know, the the wine and the cookie and and she's getting advertising at her store, you know, basically.

00:36:10

Speaker

Right. Hopefully they buy something off my shelf while they're there, you know. Exactly. You know. So, yeah, it's just like, and it's so much fun to have, hey, do you know how I could do, you know, like this thing or that thing? Hang on, let me look on Bamboo Handy, see if there's something for that, you know? Yeah, yeah like you just go quick look and go, oh, look, there's an adapter for that.

00:36:35

Speaker

Yeah, my nephew. There's what? You can't find anywhere that has C batteries? Great. Let me print you this adapter. You can put a double A in the freaking C hole with the adapter.

00:36:47

Speaker

You can wait. What? you can you can Yeah, they're both one and a half volts. Will it die faster? Yes, but it'll work for now. Yeah, I can do that. another another cool bamboo handy the thing that i discovered which is not ah like i didn't discover this but i just found it is the uh you could take a picture like if you if you need a bracket you can literally take a picture of the bracket you need and it will go out on the maker world site and find all the things that are as close to that bracket as they're made that's cool i didn't know it did that

00:37:25

Speaker

Yeah, you literally take a picture of ah of ah of a thing and hit search, and it'll go out in the maker world. I mean, you might get a Hueforge of an angle, yeah you know, but right but it'll give you everything. But the fact that it does an image-based search yeah is cool. I did not know it did that.

00:37:45

Speaker

I don't spend much time on the app. yeah I spend most of my time playing in studio, so I hadn't noticed that one. That is cool. Yeah. I'll have to remember that. It's a three.

00:37:58

Speaker

So I guess I've printed a couple of cool things. Um, I mean, last time we were talking, I'd done the huge forge frames and, had a tiger the size of a, yeah, it was bigger than a poster. It was, i don't know.

00:38:18

Speaker

It was five feet by three feet or something. yeah Um, I've got like five or six versions of that model up now. Uh, cause I mean, my original version wanted to max out the capacity of the X twos and the a one. So the pieces are like two 25 by two 25.

00:38:41

Speaker

And, but then, you know, everybody's got the a one mini, so I had to revamp it. So I had 150 by version. And then I had people that had a stack of hue forges that they printed out at 200 by 200, but they wanted a frame to put them up in as a collection. So then I had to modify it and put up a 200 by 200 version.

00:39:11

Speaker

And then somebody comes up and says, Hey, um, I've been seeing a lot of these Hueforges that are

Creating Hueforge Frame Sets

00:39:21

Speaker

bookmarks.

00:39:21

Speaker

This is another popular category that's popped up in the last few months is that people have been making bookmarks using the Hueforge software. And it's a, it's, you know, very tall and very skinny because it's a bookmark. And somebody says your, your, your frame set is, is designed as a minimum of a two by two grid. So it's two across and two high for four pieces. That's the minimum size for a huge forge frame set.

00:39:53

Speaker

Mm-hmm. And he's like, can you make ah a modified version that's only one across, but as tall as you need it? So I said, okay, yeah, we can do that. And I redid a piece that was a, the the end piece has three outer edges and one connector side.

00:40:12

Speaker

And you can print two of those and make a piece that's one across and two tall. And then there's a centerpiece that has two outer edges and two connectors.

00:40:25

Speaker

So you can put that in between two ends and then you can add as many as you want. So now this frame set can be one across and six tall, if that's what you think you need.

00:40:36

Speaker

and and And then I had to make 150 version of that. So I think that's, I think I'm done with five sets of those damned things. Um, then i found something cool. I found a, I found a brand that makes some really weird ass filament.

00:40:55

Speaker

And i just, I have to question whether any of it's very practical, but they've, it, the, the brand is called time plast.

Exploring Unusual Filaments

00:41:08

Speaker

And they make the weirdest filament. um They've got a filament that is called fire and it's meant to be burned. You're supposed to light it on fire and doesn't burn very well in thick pieces. But as long as you've got a really thin piece and light it from the bottom, it seems to burn. Okay.

00:41:29

Speaker

Like a fire starter. ah Well, yeah yeah. Well, I mean, Apparently you can burn PLA, but it kind of more melts and gets black and sooty, but this, it, it burns fairly clean and smoke free, but I, I don't know that there's really a practical purpose to it, but for my sake, I do artistic things with my digital fabrication tools

00:42:02

Speaker

because I think it's fun and for content and for content, if you print something and then light it on fire, that has potential for content.

00:42:14

Speaker

Yeah. I saw your, I saw your dumpster fire. Yeah. I mean, that was, I mean, the the first thing I did was just a test. I printed a part to see if I could get it to actually work and print and how it came out and how it burned. And I learned some things from that. And then,

00:42:30

Speaker

I went with my first actual, you know, content art project, which was a dumpster fire. And I actually found a model for a dumpster fire where it came with a dumpster and it had a section that you're supposed to print in, you know, bright red or orange or yellow or whatever. That's actually the fire.

00:42:51

Speaker

And I took that part and I modified it and I printed that part out in the fire filament. because I had to try that. And I'm not going to say it worked really well.

00:43:06

Speaker

cause This stuff's a little finicky to print with, and it's definitely a little finicky to get it to burn right. You definitely have to have thin areas with lots of oxygen room around it to work properly. Once it does light itself on, it goes pretty good.

00:43:23

Speaker

But getting it going can be a challenge, especially if you don't have it thin enough. to really want to catch. Um, but that was really cool. That was sort of fun.

00:43:35

Speaker

I also have a role I bought and it's fish food, which like edible. Yeah.

00:43:47

Speaker

Yeah. You print things and put them in the tank and the fish will eat them. I have not got a, uh, anything printed out of that yet.

00:43:59

Speaker

I, we just got done setting up a 55 gallon fresh water in our basement. And we've just got a couple little tiny starter fish in it to get the bacteria going. And we just haven't had time to get down into town and buy, you know, some actual real fish to put in there. So I haven't bothered printing anything for that yet, but you know, I'm going to print like,

00:44:27

Speaker

anything that I think will be funny to watch fish eating, like I'm going to print like a little scuba diver and then yeah film the fish eating the little scuba diver or you reenact jaws or well? No, I'm going to go with a reversal on that one.

00:44:46

Speaker

I'm going to print a shark and all the little harmless fish are going to be eating the shark as payback. Yeah. like It's a reversal on what normally happens in the wild.

00:44:58

Speaker

So, I mean, you know, I'm, I'm, I'm short on having a lot of really, really good ideas, but I mean, I thought it would be fun to experiment with these things. So I ordered a couple rolls and they're like 300 grams. So it's like a third of a roll and it's not any cheaper than normal rolls.

00:45:23

Speaker

So, 20 bucks for a third of a roll. roughly Yeah. Yeah. And I don't remember which one of them was like 20 bucks for a third of a roll. And the other one was like 40 bucks for a third of a roll.

00:45:34

Speaker

So they're not cheap and they're, they're probably not something that a print farm would buy in bulk. Right. They do have, they they do have soap filament.

00:45:46

Speaker

And I was going to say, that's like 75 bucks for a roll. landscape And I don't know if I want to run that through my printer. Well, but there's, there's, well, I don't know that the a one comes with the, the hardened steel nozzle and the hardened steel extruder gears, because this has got extra crap in it. Anytime you run extra crap in your filament,

00:46:13

Speaker

it does extra wear and tear on your machine. There's there's so much I can do with just PLA and PETG that I don't need to worry about all this hybrid stuff yet.

00:46:25

Speaker

Well, I just i just thought it'd be fun to try. yeah. Sounds very interesting. The dumpster worked pretty well. And, I mean, it didn't light great, and it didn't... And I did print the rest of the dumpster out of normal PLA.

00:46:42

Speaker

So i I did put some little pieces of thin sheet metal on the inside of it to protect a couple of the areas so it didn't melt the front before the fire really got going.

00:46:54

Speaker

um But I will say the dumpster did not really survive the attempt very well. But I did get the 10 or 20 seconds of fun footage of the dumpster fire burning.

00:47:12

Speaker

before it all went to hell. So I mean, I got the 15 seconds of content that I did this entire project to, to acquire, you know, I like, I like, yeah.

00:47:24

Speaker

yeah Yeah. And I like using it's, I like it that you're using a different material, but you're incorporating it in, in um I guess it's a natural progression that,

00:47:36

Speaker

How do i want to say this? Like the printer is no longer just the printer. You're now you're using ah a different you're using a different kind of filament and you're incorporating it into something that will eventually become content, something else. You know what I mean? You're using your printer to get somewhere.

00:47:53

Speaker

instead of using the printer as the printer. you know and i And I think we all, like when we buy lasers, we want to we want to woodburn, you know laser engrave things. And now, you know and then eventually you just start laser engraving on a project or CNC's, you know you're you do your little carvings and you make a bowl and then eventually you're cutting out pieces to make something else.

00:48:15

Speaker

Right. Like CNC carving a mold that you want to pour cement into, for example, or something like that. Yeah. To your point, we started talking earlier in the show about me getting into the Hue Forge.

00:48:27

Speaker

I'm actually printing. I picked one thing. I'm a Volkswagen junkie. So I picked a Volkswagen. It's the front of a Volkswagen van, like a sixties era van. Right. and it's It's a really cool. Yeah. Me too. It's a really cool.

00:48:43

Speaker

Four, five, but yeah. Yeah. Yeah. ah Yeah. Uh, it's a, it's a really cool, like a distressed looking hue forge.

00:48:54

Speaker

And the original is just black and white and Brown. So I changed the colors up and I printed a blue one, you know, blue shades, shades of blue. and And then I was like, Oh, you know, this would look really cool in all shades of red.

00:49:08

Speaker

And now I've got one printing right now. That's all shades of green. And the fourth one is going to be all shades of Brown.

00:49:18

Speaker

So I'll have brown, green, red, and blue, all the same picture. Right. There's different colors. And I'm going to use my CNC also. and I'm going to make a panel and then mount all these as just a piece of artwork. So I'll have 3D, CNC, woodworking, you know, all to make one project, which is kind of really cool how these things start integrating into our lives.

00:49:41

Speaker

You should probably try to find some way to laser on that backer board just to include it so it doesn't feel left out. you know I can laser some peace symbols and stuff into the wood. Yeah, good idea. Yeah, exactly. And so you can CNC carve the backer board, then you can laser some things into it, and then you can add your 3D prints into it later just to make sure that this is a collaboration of all the digital fabrication skills you've acquired.

00:50:10

Speaker

And then I'll seal the entire thing in epoxy like a river table.

00:50:15

Speaker

There you go. That'll piss people off. No, I think it'll be a good art project. I'm going to like that. Yeah. Yeah. Yeah. It's just really cool. Like, you know, you doing experiments, you know, I'm starting to do the same thing. Like, all right. Uh, a hue forge, for example, has four color or the, the you know, pick one with four colors.

00:50:34

Speaker

Okay. So you have white, black, blue, and yellow. Okay. So let's put the yellow where the white is the blue, where the black is the black, where the blue, you know what I mean? Right. And colors just rotate them around.

00:50:46

Speaker

i'm hoping it'll give me like a negative effect, like ah like a negative. It might. but's That's one of those things where you may not know how it's going to look until it actually comes off the printer. Because yeah the Hueforge model, for the the software that creates those models works on a system where you can see the color through the color.

00:51:11

Speaker

Where if you put one layer of orange down, on top of black and say, so you've got a black base and you put one layer of orange on it, that gets you a really, really, really dark, dark, dark orange.

00:51:27

Speaker

Whereas if you put two or three layers of orange on top of it, it gets a lot more orangey and a lot less blackish orangey. Or, you know, you can just like we said with the actual painting and airbrushing that if you start with a white base versus a black base and then you put a color on top of it, it changes what you see because you can see through the top couple of layers.

00:51:51

Speaker

So it'll allow you to get a range of colors. You're not just using the four colors. You're able to do a little bit of color blending it.

00:52:01

Speaker

And that's, that's what makes the software so damned inscrutable is the fact that it's, it's artistic magic and it's not, it's, it's it's not a scientific process. It's an artistic feel for it kind of thing.

00:52:19

Speaker

But, um, oh, that's the other thing I got about the, uh, the speaking of hue forges and huge forges. the The latest version of the Hueforge software.

00:52:35

Speaker

So the software you use, you feed it an image and you pop out the Hueforge 3D model that can be printed in four different colors in different layers.

00:52:48

Speaker

um That software has an update now where the latest update, he has created a plugin called Huegeforge.

00:52:59

Speaker

where you can make your Hueforge model. And then if you click on the huge forge plugin, it will allow you to scale it up to ridiculous sizes and then automatically split it into pieces of the right sizes you want.

00:53:19

Speaker

So and this was added basically. I mean, I invented the term huge forge. and then figured out how to blow these things up and cut them into pieces and put them into a frame. And apparently he thought that was cool enough that he's added the feature. He doesn't link directly to me or anything, but he used the name of my model for his plugin.

00:53:41

Speaker

So there's a program that like I can take a picture of my dog and make a Hueforge out of it. Yes. Okay. ah that That's where they all come from. Oh, so I'm just point and click. I just download them. Right. See, you're you're downloading 3D models that are labeled Hueforge, but they come from a software which one dude has developed this piece of software that does this, that you can feed it a picture.

00:54:09

Speaker

And through magic experience and good luck, it kicks out this 3D model that then looks like the picture. Yeah. And then it has a flat piece.

00:54:20

Speaker

So that is, it is actually a piece of software that's that's called Hueforge. And he's he's actually taken me taken my idea, run with it, and added a plugin called Hugeforge that will allow you to blow it up and split it into pieces.

00:54:39

Speaker

And then you can just feed the pieces at your slicer instead of having to, the way I was doing it was I was taking an existing Hueforge model putting it into bamboo, scaling it up, and using the bamboo cut tool to cut it into pieces.

00:54:58

Speaker

This is if you're designing a Hueforge and you want it to be big, you can just click on the plugin and it will automatically allow you to blow it up and it'll do the splitting into the parts for you.

00:55:13

Speaker

So I thought that was really cool that... he just ran with my idea and added it into his program. That blew my mind.

00:55:25

Speaker

Yeah. it's sir It's 25 bucks for personal license or 350 for a um professional license. Like if you're going to create models to sell.

00:55:35

Speaker

So yeah, very cool. there's There's, there's a middle line that I paid in on when I bought it was that, that you can, the The middle version says that you can make the models and then you can sell the prints.

00:55:52

Speaker

But without the full professional license, you're not allowed to sell the model. Right. Right. yep Yeah. well So if you just want to make pictures and print them out and then sell them on Etsy or wherever you want to people, you can do that with the mid tier version. I think it's about 60 or 80 bucks or something like that. I don't remember.

00:56:17

Speaker

Okay. Yeah. Cause it said, it specifies on the personal side, no, no beta access, no selling prints or models, no selling digital files. Right. That's just to make them for yourself and share them for free.

00:56:28

Speaker

Yeah. But there's a, there's a 60 or $80 tier in there. I think that allows you to sell the prints, but you have to pay the full professional if you want to sell the 3d models.

00:56:41

Speaker

Right. So, Anyway, um anyway yeah what else did I do next? Oh, I came up with this great idea that I wanted. I had some a few rolls of translucent PETG, and I decided I wanted to try to do some stained glass style sun catchers for the window.

Stained Glass Effect with PETG

00:57:05

Speaker

um And I decided I wanted to make original things here, too. so i I started with AI and I had AI, I've mainly been using Gemini, but I think I threw a couple at it, the chat GPT for the hell of it.

00:57:26

Speaker

And I just asked it to make me a design of and you know, whatever, say, say a UFO in the sky and, uh, in the style of stained glass.

00:57:42

Speaker

And then I, and and then it would give me a beautiful color picture of a stained glass UFO. And then I'd ask it to strip all the colors and textures and just leave me an outline drawing.

00:57:54

Speaker

So I can, so I can use the color picture as suggestive guides as to what colors might look good for it. And I'll use the black and white version to convert to SVG and I'll throw that into fusion.

00:58:10

Speaker

And then, uh, My first one was a unicorn and i printed a test version and it was kind of small and it was like really, really pale.

00:58:24

Speaker

The colors were really pale. So I went back and I i scaled it up so it was a little bit bigger. And then I doubled the thickness so that the panels weren't one millimeter, they were two millimeters. And then you get a lot more color because you're blocking a lot more light.

00:58:42

Speaker

So you get to see a lot more color. So that turned out really good. So I liked the unicorn and it was just a couple of colors and it looked great. And, but in the process of doing that, I'd learned my lesson that you get different colors out of the same spool, depending on how thick the area is, because it's translucent and the thicker the piece, the more light it blocks, the more color it shows.

00:59:11

Speaker

the darker the color is. So if you take a blue translucent PETG and you print a piece that's one millimeter thick, you get a very pale light version of the blue.

00:59:25

Speaker

And then if you print... two millimeter thick, it's a darker version of blue and you print three millimeters thick and it's an even darker version. And I realized, Hey, you know what?

00:59:36

Speaker

I could get some variation in color and I could print some areas, light blue and some areas, dark blue. And then I came up with the UFO model and introduced multi tones of colors where,

00:59:54

Speaker

I had a couple of shades of green and a couple of shades of yellow and a couple of shades of blue based on the thickness of each of the areas. And um that worked really well. And that looked really cool. yeah And then for my version three, I decided that I wanted to try because the light has to pass through all the layers, what you see on the front is the light that comes through based on what parts of the spectrum have gotten blocked on the way through.

01:00:30

Speaker

So I started experimenting with blending colors and I discovered that I could put down a couple layers of green and then put a layer of red on top of it.

01:00:45

Speaker

And I would get a light Brown. Or if I could put like five layers of green and like two layers of red, I would get a really dark brown.

01:00:56

Speaker

And then I've tried a couple other variations and I did a blue plus red to come up with a couple of shades of purple. And having that, and I just printed like, I don't know, it's like 25 millimeter squares.

01:01:16

Speaker

And I started printing a bunch of different little test pieces with different colors and different variations. And I came up with, you hold it up to the light and you get different colors through it. you know you can So I can throw green and red in and I can print areas that when the sun passes through it, they appear to be brown in different shades.

01:01:37

Speaker

And I thought that was cool. So my third piece, I did a Bigfoot. And there's two shades of brown in there, and I do not own brown translucent filament.

01:01:50

Speaker

It looks really cool. These things look so amazing, dude. They look like real stained glass. It looks really cool. And I do have something a little bit bigger and more exciting planned for my version 4.

01:02:05

Speaker

I'm kind of struggling with it based on the fact that I've got... five base colors in this picture and I've only got four spools and I'm trying to fight about maybe I can.

01:02:22

Speaker

And this is going to be kind of along the lines of the huge forge where I scale something up and print a bunch of pieces of it and then assemble it later. Um, much like a huge forge wall picture.

01:02:36

Speaker

um, I've come up with an idea on how I can split this into plate sized pieces. And I'm going to come up with, you know, a window sized stained glass window.

01:02:50

Speaker

You know, I mean, it's going to be, you know, two and a half by three feet, you know, something like that. Four feet. I don't remember.

01:03:02

Speaker

um But I'm having problems with, ah Some of these areas that I'm going to have to print out have got five colors in them. And I don't know, i'm I'm going to have to cut things into smaller pieces or I'm going to have to have some of the areas pop print separately and then pop into place.

01:03:24

Speaker

or sam I'm working on that. that one's going to be a struggle but i i do have a design for my version four set that is going to be absolutely fucking epic and i've got this big uh family room window that looks out of my backyard and it gets a it gets the afternoon sun really well and this thing's gonna feel like and maybe two thirds, three fourths of this big window is going to be a big panel of something fun.

01:03:54

Speaker

um But, you know, i'm I'm still struggling through that one, but I, I, the problem is, is I just can't break this design down into four base colors, even in adding, even adding in extra color blends.

01:04:10

Speaker

I still need to have five base colors because there's just too many pieces in here to make it all the same color. Sounds like it's time for another AMS.

01:04:21

Speaker

Yeah. Well, no, I don't want to buy another AMS because that leads me to some of my next plans is I've got my eye on an H2C, which is the bamboo that's coming out supposedly in December.

01:04:40

Speaker

And it's gonna have six colors plus six colors for switching heads. And it's gonna have multiple nozzles. So it won't need to purge and poop between colors.

01:04:53

Speaker

and it'll It'll still need to wind the, it'll still need to cut and wind it back up and feed the next one down in. But that's like 20 seconds of the process and it'll cut out the whole 60 seconds of purging and pooping out the back.

01:05:09

Speaker

It's funny you mentioned that because I have my eyes on an X1C with probably five or 6,000 hours on it by then. no Well, we shall see how that goes. But yeah, that is part of that. That is one part of my plan is I'm thinking that if I put a couple thousand dollars into buying an H1C so I can do six or seven, there's one external spool too. So I think you can do literally seven different colors on something.

01:05:40

Speaker

and With no pooping. um If I can put out a couple thousand dollars for that, then it would be I'm i'm questioning my logic here, but I might sell the X1 as a way to recoup some of the money on that and just do an upgrade instead of an addition.

01:06:00

Speaker

But <unk> I've got another idea, too, because I think I'm going to sell my rotary. I think I'm going to sell the rotary CNC.

01:06:11

Speaker

um i haven't gotten any much use out of it. I mean, i i had a spindle die and then i bought a bigger spindle and then I sat on it and waited because the new spindle needed a new outlet because it was 220 instead of 120. So I had an outlet put in and that took me time and money. And then then I got the new spindle up and running and then I did one project on it and I realized that I needed to program the spindle because while it works, while it runs, it's got no balls, it's got no oomph. And anytime it touched wood, it just blew smoke off of it badly. So I need to program it.

01:06:58

Speaker

ah i need to program the VFD properly to get it to work. And then while I was thinking about how I should do that, my fucking software ran out. And the only thing I've got running this rotary is the fusion 360 with the manufacturing extension to do the, the, the rotary abilities.

01:07:20

Speaker

And while I can do fusion for my normal CNC for free all day long and fusion for my printer for free all day long, if I want to use the fourth or fifth or sixth axis,

01:07:36

Speaker

abilities of fusion. You not only have to pay for the paid pro version of fusion, which is like $600. But on top of that, you have to pay for the manufacturing extension, which is another 14 16 or something. It comes out to was paying year just to be able to use this fucking toy and i making There's your printer. And I'm using three or four projects a year.

01:08:11

Speaker

Yeah. im ki I mean, now don't get me wrong. I have put out some amazing projects. I mean, that skeleton lamp that I made is just absolutely badass. I couldn't have done that without the rotary. But is that plus one or two other little mallets that I turned out worth the $2,300 a year that I'm paying for the software?

01:08:31

Speaker

No. And you can you can use a Spire with it and if you're the kind of guy that already owns a Spire and is paying for it and getting your money's worth out of it.

01:08:45

Speaker

So, I mean, you could use that to run this, but I don't want to pay for that either because that's also a couple thousand dollars a year ah for me to make a couple of fucking toys. yeah So, I think I'm going to flip my three axis, which is...

01:09:01

Speaker

left, right, up, down, and rotation, ah rotary. I'm looking around the shop going, where can I put that? Yeah, you know, I'm thinking that maybe if I sell that between now and December, I can use that money to fund the HD.

01:09:20

Speaker

two C in December and the X one, maybe I'll end up keeping the X one because I'll decide to sell the rotary to fund the new printer instead of selling the old printer.

01:09:34

Speaker

You'd get more use out of that. I think that's a smart move. And the, the other thing is, and it doesn't cost me anything to keep running it like rotary does.

Selling Prints on Etsy

01:09:43

Speaker

Uh, the other catch here is that, uh,

01:09:48

Speaker

I think I'm going to try to start selling some things on Etsy because I finally have some original designs that I think might have some marketable appeal and original, you know, and that's the sun catcher, the line of sun catchers I've got. I've got the, the the three finished designs of sun catcher and I should be able to turn those out at ah one every few weeks if i want to add to that as a product line of sun cat 3d printed sun catchers and somebody might have gone ahead and bought an extra like six or eight colors a translucent petg at this point so i'm thinking i might start printing those and putting them on etsy at which point a second printer would be nice

01:10:39

Speaker

Right. I might keep one of those printers busy putting parts on Etsy and I can use the other one to satisfy my own fun between times. So I'm thinking I might keep the X1 and sell the rotary. We'll see.

01:10:56

Speaker

There's so many, I'm obviously looking for a deal and I'd be happy to buy one from you if it was ah if it was a deal, but, um, it's, I'm seeing so many of them for sale that it's almost not worth selling them. They're, they're more valuable sitting as a backup than they are for the money you could get out of it.

01:11:13

Speaker

You know, really I mean, the X one's still a pretty high value printer, yeah but like there there's, there's printers out there. If it's, if it's not a bamboo, brand new they're under three hundred dollars now right yeah i mean especially if you get an older single color printer it's worth 50 bucks yeah if you're yeah it'll cost you more to go pick it up i mean uh uh then you know the pruses might still have a little bit of some some value but i mean if you've got a four-year-old you know even a two-year-old ender that runs on one color you can't get a hundred bucks for that right now no no

01:11:52

Speaker

well Because it doesn't auto level. It doesn't multicolor. It doesn't do any of the things the new ones do. I mean, it might be sufficient for somebody's workhorse if you want to turn out standard single color parts that you've got a need for, then... I would buy ah i would buy ah an a one in single col but it i wouldn't give more than seventy five bucks hundred bucks for it right book ah and just keep it printing you know, like pieces that are going to be painted and assembled to where I'm just printing everything in gray or white, you know? Right. Or you're printing something practical, whether it's, you know, it's, it's brackets or adapters or,

01:12:32

Speaker

you know pro You know, vacuum hose nozzle attachment adapters, you know. All my shops. You want to reduce, you know, five-inch vacuum hose to four-inch vacuum hose. You make yourself a big funnel-looking part and start kicking them things out for people. You know, something practical where you don't – not everything needs to be color.

01:12:57

Speaker

Yeah, yeah. Or more than one color. Right, right. I mean, yeah, not everything needs to come off the printer with four colors. I'm going to print, I'm going to try to print a dust boot for the the little CNC.

01:13:13

Speaker

Okay. And see if I can come up with a, I've seen a several designs, but I need to modify them a little bit to make them work for my, what I want. But yeah, so that'll be fun.

01:13:26

Speaker

What else we got here? We're getting kind of I don't know. Yeah, we're kind of running low on time. Let's ah i I do want to give a last chance at a thing of the week here. Do you have anything or should I just throw a couple things at the wall?

01:13:41

Speaker

Well, I don't know. I know you said you had one or two. um i don't have a specific thing of the week, but if this is well, if this is since this is kind of our last show and everything, I just my thing of the week is the maker community.

Value of the Maker Community

01:13:54

Speaker

You know, like there really isn't anything you can't find on the maker and the maker world. um So just explore it, explore it on Instagram, on Facebook, on your local maker sites, on, on your neighbor who has a woodshop, you know, that's all part of the maker world.

01:14:14

Speaker

Go find these people and put your hands on something and make it and take it home, you know? So that's my thing of the week. I like it. What do you got? Well, I got, uh, uh, I got a couple things I can throw out.

01:14:31

Speaker

Um, I got a couple products I've seen in the last month or two that I thought might be worth suggesting to people. Uh, the first one is a CNC accessory.

01:14:44

Speaker

It's called air weights. It is a small panel that does vacuum. It's, it's, it's like, well, you know, I mean, Al's got a vacuum for the whole freaking CNC for his big one.

01:15:02

Speaker

But say, for example, if you've got a small CNC or a desktop CNC or something that's not made to run vacuum on it, much more, you can, you can get like a 12 inch by 12 inch vacuum panel.

01:15:18

Speaker

that you can bolt down to your spoil board and then plug into a vacuum line. And then if you, if you're carving small parts that are going to stay on that area, then you can have like a 12 by 12 inch vacuum work holding area that's on your CNC.

01:15:39

Speaker

And it's the, they seem to be not too ridiculously priced based on what vacuum work holding usually costs. Mm-hmm. and I mean, it's usually expensive as shit because you're doing, you know, full bed vacuum system is going to be thousands and thousands of dollars. And so the company's called Air Weights.

01:16:01

Speaker

Very cool. So Air Weights Workholding is a cool little vacuum system for a CNC. And the other thing that I've seen that I thought was really cool is a three d printer that seems to print in clay.

01:16:21

Speaker

um So it, it takes a specific fine, fine, you know, i mean, it's obviously not a rough clay. It's a fine clay that it seems to do everything it needs to do the extrusion and the squirting out of clay as three d prints. Um,

01:16:43

Speaker

And the product, I'm not sure I can pronounce it. E-A-Z-O. It's E-A-Z-A-O.

01:16:57

Speaker

And it prints pottery. That's cool. It's like the miniature version of the concrete house printers. So, yeah, it and it it can print pottery clay and porcelain clay.

01:17:09

Speaker

I assume you still have to it. I'm sure. I'm sure. But, but the fact that you can print pottery is just kind of bad-ass.

01:17:21

Speaker

Um, leaves me with a regret. I wish I was, i I was trying to see if I could get a, I wanted to talk to somebody as a guest on here.

01:17:32

Speaker

Uh, there's a chocolate 3d printing system where you can print in chocolate. and that might be worth keeping the show going. Well, I mean, the there is a there was a girl, or lady that started this thing, and she was really cool. But it seems to have steamrolled into a giant, large corporation where it's now, it's like, well, do I try to reach out and talk to what's essentially now the president of a small corporation running a big company that's making...

01:18:08

Speaker

ah chocolate printers gets to be a little bit more complicated than some DIY backyard person to talk to. and I felt a little intimidated by that. and I'm like, maybe I'll come back to her. And then I just never got to it.

01:18:21

Speaker

Yeah. But that's a very cool concept though. Yeah. The fact that you can, anytime you can print with things that aren't normal filament, it's cool. If you can print in chocolate and have it come out and, or if you can print print in clay or some other kind of medium that makes things so much more fun yeah and interesting at least.

01:18:44

Speaker

Yeah. And I love the knit figurines, you know, that you can print that look like they've been knitted. Right. Chocolate and, and, and things like that would work perfect in that case. Clay, even, you know, you could really get, you know, get some pretty cool detail. and Okay.

01:19:03

Speaker

Well, I think we need to get things wrapped up. You're pretty much out of time. i do want to, you know, throw out a couple of final thoughts here for our

Podcast Reflection and Gratitude

01:19:15

Speaker

outro. You know, we're,

01:19:18

Speaker

it is what it is, but you know, there's the, the, the, there's money involved and there's time involved and there's priorities involved and they don't all seem to be lining up in our favor where, you know,

01:19:32

Speaker

the the The time and the priorities haven't been... and the The time has been short. The priority has not been at the top of the pile, unfortunately. And therefore, our frequency has been nowhere close to the every other week that I hoped to do.

01:19:50

Speaker

And with 16 episodes a year, I mean, I just don't know that paying a couple hundred dollars subscription fee to keep that going is That's fair. Yeah. I don't know that it's worth the trouble. I mean, although I will say, you know, we did have some good patrons that did support a couple dollars towards us.

01:20:14

Speaker

Although, you know, that, that, that comes nowhere near to paying for another year yeah by, by a long shot. where We're nowhere near a fourth of what it would cost another year in our Patreon fund.

01:20:27

Speaker

Yeah. I mean, I guess I can offset what I paid for last year's with that, but I mean, that's about as far as it's going go. and thank you for to everyone who did donate. Definitely.

01:20:38

Speaker

You know, i we we need to, you know, I definitely want to thank all the people who bothered to listen to us and to say that it wasn't an enormous amount of people.

01:20:54

Speaker

But that means that our listeners happen to be of the top 1% of the most intelligent and most, you know, of the best taste.

01:21:05

Speaker

You have the best taste in things because you found our niche to your satisfaction. Yeah. so you know, I'd like to pat all the listeners on the back for making it through this and actually finding some value in what we're doing here.

01:21:22

Speaker

I need to make a point of thanking all of the guests that we've had. one of them amazing Every one of them was amazing. And yeah, I, I was thinking about this last night and I'm vaguely curious about how many of the guests we had have been on podcasts before versus how many have never been on a podcast before.

01:21:46

Speaker

Now I know, we're probably about half and half on that one. i know half the people have been on podcasts before. i know that, uh, see Jacob other dog has been on podcasts. Clearly Jimmy's been on podcasts, uh, uh, Mary Lou's had tons. Yeah, exactly. Of his own plus 500 of everybody else's. Cause he says yes to anybody that wants to have them on a podcast.

01:22:14

Speaker

yeah Um, I know Mary Lou's been on dozens and you know you and I have done other podcasts and I know a lot of the other people have, but I'd like to say that there's at at least a solid handful of, you know there's at least five or six people that we talked to that have never done a podcast before.

01:22:34

Speaker

And I'm very thankful that we had the opportunity to do that for them and to give them the experience of being a guest on a podcast and having a chance to talk about what they do and how they do it and what they're doing. And i think that's a really fun And it's an exhilarating experience to be invited on as a guest and to hear and be able to talk about your stuff.

01:23:05

Speaker

Yeah. um So I'm very grateful that we had the platform to do that for a handful of people that have never experienced that before. So that I'd like to pat us on the back for doing that for them.

01:23:20

Speaker

And that's not really you know the center goal, but I mean, that was something else I'm, thought I'd wanted to mention that I'm thankful that we got to do. Yeah. Well, let me, let me interrupt you and say, thank you for like, and, and trusting me to be a part of this, you know, and I've thoroughly enjoyed being the the wing man.

01:23:41

Speaker

And, and, and thank you for doing it. I mean, it wouldn't have been the same if I didn't have you on here. it you know, I, I have absolutely no regrets for having chosen you as the co-host. I, I think that,

01:23:56

Speaker

It was the perfect choice. I think that we get along really well together. And I think that we had a lot of opposing viewpoints, skill sets, experiences, tools on hand that, ah the you know, we kind of yin and yang together into the the the spots that I'm strong at your week at and vice versa. And that we came together to make one cohesive, cool knowledge base between the two of us, we could figure something out, you know?

01:24:34

Speaker

ye Yeah. So I'd definitely like to thank you for putting all your time and effort into coming and helping and asking the good questions and making the show what it was.

01:24:46

Speaker

I didn't ask you for a lot as far as the podcast is concerned, other than to show up, be intelligent, ask good questions and be the, you know, to to ask the question when I'm not sure what to say and next.

01:24:59

Speaker

Um, but you, you've done that beautifully. Uh, everything I asked you for, I got so, thank you and, uh, trying to rush through this a little bit here. Cause you know, I know you gotta go, but, uh,

01:25:15

Speaker

I definitely want to make an extra big thank you to all the people who contributed as patrons to us for their support. So, um, one last big thank you for, uh, Adam from BKR customs to Ed Swanson of Ed's clocks and more to Eric from overall maker works and to, uh, just Nelson from just makes.

01:25:43

Speaker

And, uh, That has been shut off. there will be no there There will be no more funding pulled from your pockets, but thank you for contributing. And geez, I guess I don't have a whole lot to say. Oh, the other thing I wanted to mention is that the subscription on the Zencaster is running out here in another week or two.

01:26:08

Speaker

there's a good chance that the feed might just disappear. So ah it might just ah disappear from the podcast world. Like we never existed.

01:26:20

Speaker

I will, however, leave the Instagram alive. And even if the podcast feed and all its distribution channels goes completely dark, all of these episodes are in fact on my YouTube channel.

01:26:38

Speaker

So ah I think it's, ah I tried to get a weird guy. I think I ended up with it. My short name being a weird guy named Jeff or something like that.

01:26:50

Speaker

i don't know. Whatever. If you find it, you'll probably, you know, you look for a weird guy. You'll probably find me. is that Even if the podcast feed does go dark and these episodes are no longer available on podcast players, if you want to go back to something, these are still on my YouTube channels.

01:27:08

Speaker