Become a Creator today!Start creating today - Share your story with the world!

Start for free

00:00:00

00:00:01

8 Jacob Daugherty of Other Dog Design

Jacob can tame a t-rex with a laser, and prints droids that are life-like and life-sized. He’s also a guy who has figured out how to afford his filament addiction. This was a very in-depth conversation about 3d printing and I highly recommend it for anyone new to the hobby.

Things of the week:

Jacob: Shrinking tv show https://tv.apple.com/us/show/shrinking/umc.cmc.apzybj6eqf6pzccd97kev7bs

Al: Jeff’s walnut/epoxy nes cartridge https://www.instagram.com/p/DFxxd-yAfJ6/

Jeff: Total Boat epoxy pump system https://www.totalboat.com/products/high-performance-epoxy-resin

Patreon: http://patreon.com/digifabricators

Discord: https://discord.gg/hHp8Sv7vt4

Recommended

Transcript

Introduction and Hosts Introduction

00:00:12

Speaker

damn Hello and welcome to digi fabricators, the show where we learn how makers and artists use their computer driven tools for fun art and profit. I'm your host, Jeff Stein, AKA a weird guy. And with me is my talented but humble co-host, Al Schultz of New York woodworks. How are you doing the night, Al?

Casual Chat on Weather and Workshop Activities

00:00:34

Speaker

I'm doing wonderful. Good evening. How are you, sir? Oh, not bad. Not bad. Trying to keep warm up here in the cold north. Usual.

00:00:43

Speaker

yeah Yeah, we had a little snow to plow this week and other than that, just head down working in the shop. Sounds like fun. All right. Let's fire off our official disclaimer here. Even though we pretend to be experts on the internet, I would like to point out that neither of us have any actual training and are just guys winging it in our shops and learning as we go. All advice provided is based on our personal experience and possibly inaccurate assumptions and is worth exactly what you pay for it.

00:01:13

Speaker

If listening to this show causes you to take out a loan to buy new and expensive digital tools, you may tell your spouse that it was our fault, but do so at your own risk.

Guest Introduction: Jacob Daugherty and His 3D Printing Expertise

00:01:23

Speaker

So we have a guest tonight who can tame a T-Rex with a laser and prints droids that are life-like and life-sized. He's also a guy who's figured out how to afford his filament addiction. Please welcome Jacob Daugherty of Other Dog Design. Good evening.

00:01:43

Speaker

How you doing? Good evening. Good. Good. I think, ah yeah, you've you've distilled down everything I do, which is basically, I'm just working to afford my film An Addiction.

00:01:55

Speaker

It's for those of you that can't see, because we don't record a video, all I see is filament on the wall behind you there in various stages of use. Oh, yeah, that's only half. When you're saying there's there's a whole nother wall over here that you can't see. That's a that's a lot of plastic. I need all the colors, all the colors. Yeah. um my My addiction is getting me. I've probably got I don't know, I'd say 35 rolls right now.

00:02:25

Speaker

and it's almost exclusively PLA. I've got a couple of PETGs and what's the rubber one, TPU. I think I've got one of those just to play with if I feel like it.

Managing 3D Printing Materials and Storage

00:02:44

Speaker

With my racks that I just finished redoing the the room, with the racks on the wall,

00:02:50

Speaker

I can hold right at 200 rolls, plus within them like what's on the machines. The machines will hold another 28 on top of that. So right at 230 is what I can hold. And so my rule now is if I want another color, I have to make room. So there's a handful of old ones that are gonna have to go away for new ones to come in, because I'm not gonna build another rack.

00:03:18

Speaker

Uh, if I can't get it done with 230 rolls, I'm doing something wrong. So maybe 231 230.

Exploring Basic and Advanced 3D Printing Materials

00:03:24

Speaker

Right. Well, I mean, you can always find something to print with some of those older colors that you want to retire. You can just, you know, I mean, it's not like we're throwing it away. Just push it through the machine. Oh, absolutely. Yeah. Now, as a, as a person, let's, let's assume you might be talking to somebody that doesn't know anything about 3d printing. Well, let's call them out. Right.

00:03:47

Speaker

and What is the, I hear like letters like PTG and PLA and. but and So meso morphine Your most basic kind of starter filament is the easiest one to To print it's a it's a bioplastic that's made it's not a petroleum product is based off of like cellulose So I think it comes from a lot of other thing comes from corn. Oh, it's green. So it's somewhat green So it's

00:04:24

Speaker

pretty like it's more of a but ah filament that's good for decorative type models it won't won't withstand UV for extended periods of time it won't stand high heat like if you had it in your car in the summer it would melt so as like but that's What makes it not great for that is what makes it easy to print, which is a low melting temperature. It melts quickly, and it melts at a relatively low temperature. ah problem so But that's your that's your most basic filament. And because of that, it's the one that has the most variety. you know Multicolor, matte, glossy, sparkle, glow in the dark, all of that.

00:05:03

Speaker

Getting beyond that, you have something like PETG, which is very similar. As a matter of fact, I guarantee you have some in your house right now. It's what milk jugs are made out of, so it's a really common plastic for consumer products. It prints almost as easily, not quite as much variety because of the nature of the plastic. It's always going to be more glossy.

00:05:24

Speaker

But it it'll stand a little bit higher heat. So if you got something you're gonna put in the car, I do license plates, the front you know vanity plates for the front of the car, PETG, and they'll live outside in the sun, no problem. And then beyond that, you have stuff like you said, t TPU, which is like a flexible filament.

00:05:42

Speaker

And then you can get into stuff like ABS, which you're familiar with. It's just like injection mold stuff. ASA is is similar to ABS. Those are a little bit more toxic, a little bit more difficult to print. You have to be a little bit, you know, enclosed space on your printer for the fumes and also some Filaments don't like to have drafts when you're printing because of the way the the plastic shrinks as it cools.

Jacob's Journey and Financial Aspects of 3D Printing

00:06:06

Speaker

So you have to have a more controlled environment. Another thing another reason why PLA is where everybody starts is because it's probably the most forgiving as far as basically any machine will run it. So the majority of things 3D printed is going to be that PLA. Yeah, absolutely. Yeah.

00:06:24

Speaker

yeah Everything I sent you out. Yeah, that's PLA. Yeah, it's it's the the the cheap easy to work with with the most colors available. It's super cheap, super accessible everywhere, but just don't put it out in the sunlight. Don't put it anywhere warm.

00:06:44

Speaker

because it just won't stand up to that. But it's good for little toys and fidgets and stupid little shit that you put on the shelf, which is what I print so much of. It's actually it's actually surprisingly strong filament, but where it runs into problems is it it deforms under load over time. So if you build like a hanger or something, like you know something where it's weight pulling on it, even if it will withstand that weight,

00:07:14

Speaker

load over time causes it deform to deform where other plastics would hold up. Like PETG will be more likely, is actually not quite as strong technically, but because it has a little bit more flex, it's going to bend, whereas a PLA would more likely to shatter. So you actually can get a stronger print out of the PETG because that little bit of flex allows it to hold more weight without breaking.

00:07:42

Speaker

Whereas PLA is technically stronger, but because it will crack under load instead of flex It will hold as much even though it is a stronger film And then you get beyond that you get really into high-end like engineering grade filaments which you don't see a whole lot like so give you an example like roll a PLA anywhere from 15 to say $25 a roll you can get into engineering grade carbon fiber nylons stuff like that where you're talking

00:08:16

Speaker

you know, $80 for a half a kilogram moles. So, you know you know, six to 10 times as much. yeah But they're also, those in engineering grade filaments are legitimately engineering grade. You can do, you can print, although there's guys that can print components that will go on motors. Like you can print them in cars for cars and they will last on the motor.

00:08:42

Speaker

is the Is the finished is it is the finish different between all these or is it all structural and use? Yeah, no, I mean you're gonna get like, you know, you could do a a carbon fiber nylon because it has the knife of the the carbon fibers in it will typically have a rougher surface so it's like it will look different printed but most of your engineering grades it's basically they come out they're going to be black or gray you know they're not going to be they're rarely coming a huge variety of colors it's basically here's this thing

00:09:20

Speaker

We only sell a little bit of it to a couple of companies, so we're not making it in 150 different colors. you know rights This is what you get. This is black. Yeah. It'll do what you need to do. It doesn't doesn't have to be pretty. Right. and i Thank you so much. I didn't mean to jump off in that. Usually, I should have said, hey, introduce yourself. Tell us what your toys are and explain what you do real quick. Oh, fair enough. Yeah, i sorry. We skipped over that part. My apologies. So, I'm Jacob Daugherty. My Instagram is otherdogdesign, even though I don't really yeah post on it very much at all. um And that was just me and my wife, we when we started making stuff, we just decided to come up with a name and it was, the initials are odd, and we thought it was funny, and our dog's named Other Dog. So, you know, it's in our logo is our dog.

00:10:11

Speaker

So, but my thing, I was a serial hobby collector for most of my life. I would get into something just long enough to buy all the toys and then never actually do it. So until I found 3D printing and that's kind of been my niche since then. It's the one thing that's kept my attention and I really gravitate to.

00:10:33

Speaker

I

Running a 3D Printing Hobby Business

00:10:34

Speaker

kind of started in the maker community with a laser cutter and some basic woodworking you know kind of got it met up with a group of people met Jeff through that group and was mostly laser cutting for the the first little bit but then once i got my first 3d printer the laser cutter just started grabbing you know it basically gathers dust now it's it's all about the 3d printer and i'm up to i've owned 10 so far but i have seven that run they're actually in operation now so and you keep them busy Al's muted he's talking to me but

00:11:13

Speaker

I'm sorry, my apologies. so you're So this is your job job? This is what you do for a living? No, no, no, no, no. Oh, okay, okay. it's my father No, this is a hobby that basically the only thing, my goal is to make enough money off of it that it I don't actually put any money into it. yeah So my hobby is completely self-sustaining at this point. I haven't had success at that.

00:11:37

Speaker

So what? Are you having any success at that? No, actually it does work. it's um is a I haven't bought anything for 3D printing since my first 3D printer. Everything else is paid for by 3D printing. Which means that I can buy whatever I want and don't have to look at my budget because the 3D printer, it's different money. It doesn't count. It's not real money. yeah so That's a good way of looking at it. I like it.

00:12:03

Speaker

yeah Um, but yeah, so it's, in ah and, and, cause I'm terrible at making money, but luckily my wife is a little bit more entrepreneurial. So usually I, I just do this part and I hand her a box once a week and said, you know, get rid of this, give me cash. and That's kind of the way it works. So is your, is your wife looking for work? I've got boxes and stuff.

00:12:31

Speaker

Yeah. That marketing is a, that's a thing. i haventt i Haven't figured it out. Well, I mean we're lucky we Right up the street from us is one of the largest flea markets in the southeast Okay, and her mother had been like had a booth there for ah years doing candles and making decent money so we uh we bought a toy business so we actually own a toy store uh at the flea market it's a physical store it's not like a table once we get an actual physical store so we have a toy store and we were just one of those things well why don't we throw some of my 3d printing stuff in the toy store and uh we did and it actually did pretty well so now we actually have two stores the one that does uh toys and then one that does my 3d prints

00:13:15

Speaker

and But again, she runs all that. I just hand her the merchandise once a week. yeah she was This sounds like a full-time job. i have prevent I never want to sit down and actually try to figure out what I make per hour doing it because I think it would just depress me. right it's you know But it keeps me busy. and mean yeah If I wasn't doing this, I'd just be sitting staring at TV and I'd make zero off of that. so There's something to be said for protecting your peace. And if this is something, if this is your piece, then roll with it, man. Yeah. yeah i'm I'm certainly not trying to monetize it to being a, like a job job. I have a job that I like, uh, it's a good job. So I have no interest in trying to take the same that I enjoy doing.

00:14:07

Speaker

And then putting the pressure of being that that thing is now putting food on the table. Like I have no interest. Yeah. Then it's not fun anymore. Yeah. Yeah. Good for you. That sounds like a pretty amazing plan. I was going to ask, what kind of things do you normally like to print?

00:14:23

Speaker

So my bread and butter is your your your typical articulated dragon flexy fidget like kid toy type stuff. That's the majority of what we do.

00:14:39

Speaker

and what I mean, it's what people want. Do a lot of like, you know, Pokemon, like little, you know, again, the art actually the Articulated Dragon that everybody sees, I keep up a commercial license to that guy's account because it's the thing that sells the most, you know. It's people level, absolutely level.

00:14:59

Speaker

They fund more interesting like, you know, I enjoy the big projects like the the battle droid this full-size, but it's you know, I will sell Twice as much dollar amount in $15 dragons as I will a battle droid. You know I'm saying can I ask what that thing cost? I

Managing Large 3D Printing Projects

00:15:24

Speaker

Cost to make probably about 250 maybe a little bit more so I usually it's It's usually a pretty easy calculation I typically Quadruple the cost of my filament and that's what I charge for stuff. Yeah, so you grant Yeah, that usually covers

00:15:44

Speaker

you know electricity and time and any incidentals and helps pay off the machines and stuff like that it's not a very you know there's there's guys that have super spreadsheets and they figure out everything to the penny and blah blah blah this is how much you're supposed to charge for your stuff and I'm just like well I could do that or I could just weigh it and make it easy on myself so so so in in the In the design of the podcast here to learn how to do things Give us a thumbnail of how you start and end up with a six and a half or seven foot droid Well, I mean, you know and you guys were talking to Chris Rayleigh about this is like the I'm the guy that really does just Mostly down like I do a lot of downloading and just pressing the button um So I mean, you know for the battle droid it was finding the right set of files where I what

00:16:38

Speaker

So I think what goes from just pressing the easy button like y'all were talking about to some level of skill is I think you can the more that you print and the more that you see if I do this thing it causes it to fail. If I do this thing it makes it look prettier or if I do you know if I change this setting it's smoother and I don't have to sand as much or paint or blah blah blah if it looks better coming off the build plate.

00:17:04

Speaker

You know, so there's a level of skill to know how to adjust things to get the best possible quality, the easiest. And I think that's something I'm really good at. um my My quality is pretty consistent and my failure rate's pretty low. wow And there I think there is some skill to that, but I definitely don't consider myself like any kind of,

00:17:31

Speaker

Artists or anything right and I don't take any credit for any of the stuff I make because there are truly talented designers out there that are making stuff and I'm happy to Pay them to license to sell it, you know And eventually I would like to be one of them Designing the thing and then I so I actually do feel a little probably a little bit more pride for Some stupid little license plate or something if I design the file start to finish as I do some huge You know the full-size battle droid because you know, I was responsible for the paint on that but the file itself the impressive part the 3d shape I had nothing to do with Right. How long the print is that? What's that? How long does it take to print one of them? Oh Couple hundred hours, I think roughly over multiple printers or totally. Yeah, usually what I'll do with that if when I print one of those I have printed

00:18:29

Speaker

three of the pit droids and two of the battle droids so far. I'll usually just knock off one of my printers and it just runs on that printer is responsible for it so the rest of the fleet can do something else. Because if I get to head down in one project, I'll neglect everything else and I'll just have a backlog of stuff that You know, she'll put in orders, you know, hey, I need these, I need those.

Deep Dive into Filament Types and Printer Maintenance

00:18:54

Speaker

If I don't allot some of my machines to keep those, I'll get behind. Yeah. Right. You'll have an empty box to hand in at the end of the week. Do not want an empty box. yeah that's ah That's a good point that you brought up there. Like I can easily get like, I call it getting stuck. You know, I'll have five things going and then I'll just start focusing on one thing and then all of a sudden I haven't done anything for the

00:19:20

Speaker

a few days or a week or whatever. Yeah, I'll I'll usually try to keep at least one printer set aside for whatever project is is tickling my fancy like right now I'm in the middle of printing a fully 3d printed model railroad and it's like the tracks are 3d printed that the truck like the the trains the cars the wheels everything and you motorize it and you control it with your phone and because the tracks are 3d printed you don't run the electricity through the track you run the like you have a battery in the in the engine

00:19:56

Speaker

And then you it's running off a little ESP32 board, so you program it and then you can control it with your phone. It's got Bluetooth and everything. And you just USB charge it at night or whatever? Yeah. Yeah. So... Can you send me an email when you're done with that one? Really? I'm building ah a building a backyard bar.

00:20:15

Speaker

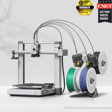

And I want, I want to train running around, around the top. And I think yeah having a maker train would be even better. yeah He's also looking for excuses to buy a new printer. Yeah. yeah is He doesn't have one yet. We keep talking to people about how cool they are. yeah Um, I mean, um What are your printers back here? I see the two are they so so i started with a Prusa and I can't say enough good things about them. It got me getting into the hobby. I no longer have that Prusa. Now um um I'm mostly bamboo. I've got an A1 Mini and then I have an A1 Mini at my shop that runs on the weekends.

00:20:55

Speaker

have two A1s, two X1 carbons, and then this is the new one. It's a Creality K2 plus, the big boy there. right I was waiting on bamboo to pull it out of extra large printer and they keep dragging their feet and not doing it. So I finally gave up on them and went with Creality. Is that the one that, and forgive me, I hear I believe it was Bob Claggett was talking about. It has four tables. No, that's the orange Storm Giga. And that one is literally so big you can just sit in the center of it. Yeah, he said it's like a dryer. Yeah, no, it's ridiculous. This one is, so that big one right there is like 350 by 350.

00:21:42

Speaker

The orange storm is like 800 by so four of those Wow, it's it's so big. It's pointless like that was Yeah, I haven't really heard anything good about those He said he spent a lot of time and he still didn't get the tables all coplanar Yeah, I think it was more of a hey we did this cool thing versus hey, this is an actual useful thing We put four printers into one cabinet it's It's look how big it is, not look what we can do with it. Yeah, I mean, it's it's one thing to make it big, but if it's not good, and and probably the the one, and honestly, the reason I think Bamboo has done so well is they figured out their machines are really good at one major thing, and that is a good first layer. And like the most important thing about a 3D print is the first layer.

00:22:40

Speaker

Because if as long as you're file like if it's a decent file, if your first layer goes down good, you're going to have success. But I don't care how good your file is. If you don't have a good first layer, your print's going to fail. It's going to fall off. i mean yeah that let's ah be for the For the people who don't do this very often, failure is, ah in my experience, 90% because the part let go of the plate.

00:23:07

Speaker

Um, normally if it just, it just falls off and then it starts doing whatever the hell it wants and paint and spaghetti in the air. Um, or sometimes yeah sometimes the parts will shift over and then get stuck like an eighth of an inch from where it should be. So you just get like a layer shift halfway up your part with a bunch of mess on it.

00:23:30

Speaker

Yeah and yeah and so that that adhesion to the build plate you know that's a good first layer good model but honestly I can say even over the last couple of years the technology of what build plates are made from has changed the game on that like I you know when I started printing it was the like the like Prusa was making a name for itself because it had the PEI plate and that was good and then the textured PEI plates came out and those were even better and now I don't even mess with those because you have like the like I think dark moon it's basically these epoxy plates and they will stick like crazy with no heat or very little heat

00:24:12

Speaker

So I've actually reduced my energy usage because now I don't have to keep my build plates hot 24 hours a day because I used to have six heaters basically running in this room and the room stayed hot all the like the main heat source is gone because I can run a cooler plate and I mean these things absolutely like it's based some i've I've had one that was sticking so well that the print tore itself apart trying to get it off the build plate like it was so you know so like they've as The the hot like as the the technology has improved they have made that adhesion to the build plate So much better that now you can print stuff. It's easier to print stuff like, you know, it's it's easier to do super detailed tiny things without expecting something to fail like, you know when I first got my

00:25:06

Speaker

My Prusa, some of the stuff that I print now without even thinking about it, I used to have a 50% failure rate. But because it was, there was so much model with such a small footprint on the build plate that half the time it would pop loose. Well now i I hit go and don't even look at them. I just come back when they're done. You know, it's, it's, it's wild what they'll do. So which, which plates are you actually using? Are you using the bamboo plate or is it a third party?

00:25:32

Speaker

um Okay, so both. Bamboo has one called the Super-Tac Cool Plate that has crazy good adhesion and a pretty smooth surface. I use Dark Moon Plates, which was one of the first ones to do those epoxy plates. They're really good, a little bit more finicky. And then BQ, B-I-Q-U, has the panda, the the the glacier plate, they're the blue ones.

00:26:01

Speaker

Those are very similar to the dark moons and they have crazy good adhesion also. So it's ah it's a mix. I have a, I have, as much as I have a filament buying habit, I also have a build plate buying habit. So I have probably, I average four to five build plates per machine. So just, cause every time I see a new one, I have to buy it to try it and see what works. Are they expensive? Are these expensive pieces? I mean, you know, 30, 40 bucks. But again, how it's not real money, 3D pentameter made it. So how don't it doesn't matter.

00:26:38

Speaker

that was real moneys not real money he's kind of like my wife again al yeah

00:26:47

Speaker

I've got one of those super tax in my cart right now right next to the 0.2 mil nozzle I Gotta push go on both of those one of these nights both worth printing. are Now. Do you have a which printed yet?

Balancing Speed and Quality in 3D Printing

00:27:03

Speaker

I've got a carbon I okay So I haven't ever messed with changing in the nozzle on the carbon because it's so like I've It's not difficult, it's a quick fairly quick nozzle change, but it isn't easy, easy, because you have to pull the wires and they're really finicky or whatever. I say like the A1s have made the nozzle changes so easy that I swap. On my mini, it'll go back and forth. but like One pram will be a 0.2, the next pram will be a 0.4. They're back to a 0.2, then back to a 0.4. I just swap every other pram, because it's it's literally a 30 second nozzle change, and you do it cold.

00:27:41

Speaker

Okay, so that I mean just absolutely wonderful. So I love like I basically have never had any reason to get a point to on my carbons because My mini and honestly that a women is a perfect machine for point to nozzle because You're gonna your prints are always gonna be so small with a nozzle that size that you do not need a full-size build plate So that that becomes the perfect machine for it That makes sense Is that a good starter machine? Like I was looking at these X1 carbons and I just don't have a thousand dollars to start something. yeah is but Is there a good machine out there for the money? I mean, I'm, I also believe in, if I've got to spend 80% of my time messing with it to save $200, that's not worth it. Okay. So yeah, there are, there are two parts of that. There's two different hobbies with 3d printing.

00:28:32

Speaker

There's either one hobby is messing with 3D printers. There's another hobby that's printing stuff.

3D Printing's Role in Manufacturing and Entrepreneurship

00:28:39

Speaker

And I always wanted to be the printing stuff hobby. So, and that's why I think like Prusas and bamboos, they just work. You do not have to tinker constantly. For the money, I think an A1 is an amazing printer. Which costs about what? To get it? 300 bucks. 300. Okay. I think it's maybe, if you want to get the four color, it's maybe 450.

00:29:04

Speaker

yeah So it'll do color changes too. yeah it's just right This is just a smaller scale. Okay, so the A1 is the same size build volume as the X1 carbon. It's a Betslinger, not a... Not a core XY. So basically with a core XY your bed moves up and down in the Z axis and then the head moves in your X and Y axis so You're the advantage to that is you don't have any movement on your part so on what's the the traditional type of printer is ah what's called a bed slinger your

00:29:43

Speaker

Your y-axis your x-axis or your y-axis y. Yeah, your y your bed moves forward and backwards Your head only moves left and right and then the head moves up and down. So The issue with that is is inertia if you have a tall thin print even if you've got good adhesion when that bed is moving The bottom is moving. There's torque on the right. It's inertia for the top is leverage, right? So with a core xy you don't have that because there's no movement to the part itself Except for up and down so but Those are edge case type stuff if you're wanting to save the money. I mean middle ground is a p1s and

00:30:33

Speaker

that's Core XY solid machine does most of the stuff in the X1 carbon will do But if you really are not sure about 3d printing and you only want to spend a couple hundred bucks And a one is awesome if it's if you think in mostly small stuff like fixturing for around the shop like little stuff the They won minis a wonderful machine Absolutely wonderful. Both of them are great now When you say small like like battery holders and stuff like that. Yeah and a one many will do that all day So basically think I think it's something like 180 cube so ah hundred eighty elevators go go Pull out that metric tape measure you got over there gonna plug it no you've got one So you have a CNC you don't know like you don't do everything in metric no no I

00:31:25

Speaker

but so He's got a co2 laser and a fiber laser and he still thinks and works in 180 that would be 18, right? So yeah about seven and an eighth Yeah, that's pretty one many and then your x1s a1s and your p1 are all 256 cubed Okay And then the big boy there is like 350 Oh, so cubed. OK, so seven by seven by seven. All right. Yeah, right. That's that's the mini. The mini does like seven by seven by seven. The the a the normal A1, the P1 line and the X1 line are all 256, which is ah about, I think, 10 inches. Yeah, roughly. So it and that's cubed. So it's 10 left and right, 10 front to back and 10 top to bottom is your build capacity.

00:32:26

Speaker

But if you never need to print anything bigger than seven inches, you can save money and get a mini. Yeah. I'm looking at, oh, it's an open. Okay.

00:32:37

Speaker

A1 Mini Colorful Gateway to 3D printing, $199. And you can spend a little bit more for that if you want the multicolor. That spool thing. yeah Yeah. And I mean, and it doesn't just do multicolor. One advantage to that is the auto auto swap, which means like, so if you run if your spool runs out, you can have a second like you can have the backup spool and it'll continue to print so your print doesn't stop. in sheet They've solved a lot of Yeah, you can put three, three rolls of gray on there and just let it go. Yeah. All right. Uh, let's see here. Bamboo Libby. I ah had a friend that found, uh, found the auto switching on accident this morning when he, his

00:33:23

Speaker

ah Black ran out and it just grabbed the next color blue and continued his print Well, it only did that because he probably I'm gonna guess I don't know I could be wrong I'm gonna guess that he didn't have his filament map right in the software because if it's if it thinks it's different colors it will auto won't it You know, it'll only auto switch if it thinks it's the same thing one to the other it's not supposed to do that word it says but if you don't take the time to change the colors when you load stuff and half the time i don't like i'll load something in the ams i'll look over a slot three okay slot three is what it is uh but if you doesn't matter if the machine knows whether it's blue as long as you know did

00:34:07

Speaker

Right. The blue part needs to run on spool three. It really doesn't matter. As a matter of fact, I started doing, there's some stuff that I'll do all before I could do eight colors. And there was some prints where I needed more than four colors.

00:34:22

Speaker

I would have it where, like, let's say, uh, color one through four was to a certain point. Well, when I got done with color one, I would pause, I'd have the print pause. I could pull that one out and pop color five in the same slot, but not tell the machine that that was color five. You know what I'm saying? So it would continue on thinking it was the that original color, but I was actually getting the fifth, sixth, seventh, so I could get eight colors out of a four color machine with a little bit of creative slicing.

00:34:56

Speaker

i've I've heard that trick for is supposed to work with the the Hue Forge because you never need to go back to the first color again. so i mean with you ford i mean I've seen Hue Forge go back to an original color like ah once or twice, but most of the time it'll print color one and then go to color two and then color three and then color four. and I understand that if you've only got one AMS with four slots,

00:35:23

Speaker

Once it's done with color one, you can pull that out and put in color five. And when it once it gets to the end of four, it'll start back on one and reach for that for the next color. I haven't tried it yet. It's on my to-do list. What's that? You forge?

00:35:42

Speaker

Oh, no. Well, I've done you projects just just i just ah a hue forage that's got more than four colors. Yeah. I want to try a hue forage that's got five or six or seven colors and do it with the one AMS and just switch them halfway through. i've done I think ah seven. I think seven rates and most I've done.

00:36:03

Speaker

Which, um that's another thing I'm loving about this, the big machine that I just got, is now I can do bigger. So I can do 300 by, you know, 300 by 300. And then I usually do, I won't max out the machine because I also designed a frame that goes with all my new forges, so I need an extra.

00:36:22

Speaker

a little bit of space for that, because I want that to fit on the machine too. So I usually do them a little bit smaller than my build size. So I have her to build the f front put the frame around it. It's a separate print, but you know, I want to have the the frame prints as one piece. So I need to have the actual the space that will fit on the build plate. So how about these AMS? Like I understand, well, I don't understand at all, but I see that they're like four colors, but I've been told By the podcast that you could do eight or however many how 16 16. So is there is there a manifold with 16 inputs? Is that how that works? Yeah. Okay. So the a ones Like an a one mini you're limited to four

00:37:08

Speaker

because they they don't have a way to, you can't stack the the the AMS is the ms light is what comes with that that one. but yeah That's $369, by the way, for the, with the AMS and everything. Yeah. So the X1 P1 line uses the traditional, the original a the original AMS yeah automatic material system, I think is what it stands for. And those you can get, those will daisy chain together and you can do up to 16.

00:37:38

Speaker

and Basically, it's a PTFE tube and a data cable that runs out of the back. You daisy chain them together. and Initially, when they started doing it, there was a ah hub that you would buy. but i Honestly, I don't think you need the hub. I think you can you just you can get a four-line splitter because it only runs one through at a time.

00:38:03

Speaker

So that's the advantage. like So the AMS, what it does, it'll roll the filament all the way through your boat until you've all the way into the machine. print. And then when it's done, it rolls all the way back out until and then the next one rolls all the way back in. And it says it's just the nature of the design. Okay, MS light, you actually have four separate PTFE tubes that go all the way to your extruder head. So when it color swaps, it only has to back the filament up about two inches. So it actually will do color changes faster

00:38:36

Speaker

And the so they're actually they figured some stuff out with the a ones that it will so it's technically a more advanced printer than the older x1 and p1. So like that pen when we were kids that had the four colors in it. Yeah, it just exactly like that. I mean, literally exactly like that because you have it's a a manifold and basically all it is four in the top one in the bottom. And it's a cone shape.

00:39:03

Speaker

So when it goes in, it just auto directs it to the the hole in the bottom. It's super simple. And it's just every time it switches, it pulls it all the way back. So it's past that junction point. Yeah. Basically it takes it. I think it hangs on to what, like the first four to six inches in the AMS. Otherwise it winds everything back onto the spool. Yeah. Well, that's, yeah, the original AMS winds everything back into the the the unit itself. So it's right, you know, puts out a, a Another advantage that too is you have to have more filament on your roll for it to work at AMS because when you get down to those last Couple of feet I've had like if if the print yeah I've gotten it down right at the end and if it had been printing on a With the AMS light it would work but the regular one because it needed that all that filament to go through the tube It failed like yeah I ran out of film

00:39:58

Speaker

You know what I'm saying? The one of those weird edge cases that you don't really run into. yeah but you're at ah You're at a filament at the roll, not at the nozzle. and Right. And there's 18, 24 inches between those two points. Exactly. With the full AMS with the big ones. so is there a I notice yours are up on a shelf. Is there a distance that you have to be within with those things? or um It's just a matter of how much filament you want to use.

00:40:26

Speaker

Yeah, it's those are probably a little bit further away than they probably should be you run into a couple of problems Friction in the tube will never like I'm probably working my motors a little bit harder than I necessarily should I just try to keep the lines as straight as possible. So there's tiny sharp bends and that helps reduce it but also it's gonna run and for a certain, like when it when it sends the filament in, the machine expects to get it at the other end within a certain amount of time. So if your run is too long, it won't have time to get there. But you have a fairly decent amount. They've got it enough to where you could stack them up, like four of the machines up, and have room for it to get the ah to be yeah the prehead. So it's you know it's not...

00:41:15

Speaker

you got some margin for error there. yeah good This is really bizarre technology just sitting here talking about this like, you know, as a Gen X kid, I'm just like,

Economic and Community Impact of 3D Printing

00:41:26

Speaker

yeah, always. i mean it's yeah Jetsons shit here. um like know You guys said that you wanted like the the technical part of this stuff. So like ah like about it, because this has been my kind of day to day obsession for years, I can talk about it at length. Yeah, but it's it really is a I think it's a fundamental change in the idea of

00:41:56

Speaker

small scale manufacturing. I think we're going to see in the next, you know, in the next handful of years, it's fundamentally going to change how i mean manufacturing prototyping works. There are plenty of like the idea of all the old people that we know on Instagram who have legitimate livelihoods manufacturing something in their garages.

00:42:21

Speaker

Like that, hell I do it, you know? Like that's, you couldn't have that. And not only that, like I make little toys, but I make a hundred different things. Even 15 years ago, for a company to make as many different products as I do, it'd have to be a like a multi million dollar company with huge injection molding machines. Like, you know, it would, it it would be a factory, a full on factory, but it's all, all of it's housed in my hard drive.

00:42:50

Speaker

It's on demand. i don't I don't think Mattel has made a hundred board games yet. Yeah, pretty cycling the same damn once though. So, I mean, and that's just, you know, back when, you know, you know, Jimmy duress always talks about being in the Toyota business. There's no rest or reference.

00:43:08

Speaker

I toss it in because i figure every major podcast has to have one. I figured I would throw it in. We have not had a single episode without a duress to reference yet. So I just had to call it out. Keep calling it out. But it actually is relevant this time. It wasn't just a ah to toss it out, to toss it out. He's always relevant. Right. Talk about being in the toy business. And you know you would design a thing, and it was such a hurdle to get it to the to the prototyping stage because that like the investment to make the injection molds and get even like the the amount of money you had to put in to just get the first prototype to see if it was any good. So i mean the so that's why only like major corporations make stuff.

00:43:59

Speaker

now You spend $300, you can prototype all day long. And so you can iterate. You can constantly change and update. You don't have to get it right the first go route. If I'm coming up with design, I can have 50 different versions and all it costs me is a few cents in plastic. And that's a fundamental shift in how everything is done.

00:44:23

Speaker

of yeah And as they figure out the technology and the the computers and the slicing gets better and the computers get smarter and algorithms get more consistent, we are edging towards the 3D printer as an appliance, which means a non-technical person can go buy one, put it on their shelf,

00:44:47

Speaker

and run it from their phone. you know And they don't know how to know how it works. Just like no most people don't know how a refrigerator works, but they put their food in it. They're gonna not know how a 3D printer works, but they can print a product. We're getting close to the Star Trek replicator state where you just tell the computer you want this product and it just creates it for you. Basically, like when I was, you know, when we, like, and these are to the point, I have,

00:45:18

Speaker

found a model, decided on it, sliced it, and sent it to a printer from my phone. I didn't have to download anything. I didn't have tolo didn't have to have a slicing software. I did it entirely from my phone within the app from start to finish. Like that that technology now exists. So sort of you do you see like a a

00:45:43

Speaker

to your point, like a tabletop little enclosed thing that you ordered on Amazon, you unbox it, you put it on the kitchen counter, or plug it in and connect it to your wifi and it connects to a library. And then you just say, Alexa, print me a six inch fidget dragon. Oh, so yeah. We'll get it eventually. She's going to try. Yeah. I mean, we're not, we're not quite there. I mean, we're not there yet. There's right there's still a level of, I mean, cause I mean, it is squirting out molten plastic. There is, you know, stuff that sometimes goes wrong. It's in any, again, any, you know, we're just getting beyond the the hobby, you know, up until really up until the bamboos, like every 3d printer was just a,

00:46:36

Speaker

a slightly more sophisticated version of the ones that guys were building in the garage out of like spare parts. I mean, printing weed eater strength. That's where it started. Really? Yeah. That's why, but if you look, almost all filament, looks it's right about the same size as a weed eater strength. It was a readily available thermoplastic that you could get anywhere. It was relatively consistent in size. It was just what's available. So that's what they started with.

00:47:04

Speaker

wow Well, no wonder as a landscape owner, no wonder weed eater string was so expensive. You guys are printing it all.

00:47:13

Speaker

So what kind of plastic is weed eater string? Usually nylon. Nylon. Nylon. And oddly enough, whereas most of the plastics that we use on 3D printers now get more brittle if they, they're hygroscopics, they suck in moisture. So they get more brittle if they get wet. Nylon's the opposite. It actually gets stronger. So we actually we actually soak our rolls of trimline in a bucket of water. Yeah.

00:47:43

Speaker

so

00:47:46

Speaker

Yeah, I think we're not we're not there yet. But yeah, definitely like it's we're getting closer. For sure. To the point where you can open the app on your phone, you can say, Ryobi battery holder and pull up 16 options. You can pick one that looks like it's going to fit in a workshop where you want and it holds the right number of batteries and then you can push three more buttons and back at home in the shop, the machine fires up, starts whirring. And you by the time you get home, it's sitting there waiting for you. So we're not too far. I mean, it's it's not programmed into a Alexa. And I don't know that it ever will be, because I think that's losing money for Amazon, although they can afford it. I mean, they find a way to monetize everything. I mean, they'll no they'll they'll figure that part out.

00:48:43

Speaker

Like, oh, you'll you'll be buying from their prime library model. library Well, actually, and honestly that actually is the, the, that's pretty relevant because one of the, you know, you've got multiple repositories online now, you know, the original was thing of hers, but you know, that one's kind of obviously at this point that you've got maker world, printables, things, both 3d, there's millions of models, but there's very little,

00:49:10

Speaker

oversight as to what's actually a decent model. know is You can print the wall battery holder, but maybe the guy who designed it was kind of a dumbass and it's not a very good to wall battery holder. You know what I'm saying? So I think where the monetization and like the Amazon and that type of stuff is going to come with with curated products. You know, when you pick the thing and say the print it, you're also, the reason you're paying for it is because you're paying for the assurance that this is a well-designed model that is printable and will fit and will do the thing that you're asking it to do. So, I mean, that that level of curation is is a thing that, that's probably where they can, not only paying the creators of the models, but also they're monetizing that curation. yeah So, I feel like that's where, so you'll have,

00:50:07

Speaker

You know, Amazon will have a smaller library than fangs or printables or maker world, but in that curated library is curated. Every model there, you know, is a good one. Right. Speaking, speaking of models, Jeff, you'll get a giggle out of this. They, they, uh, most of the guests give Al a bunch of crap because he doesn't have a 3d printer yet. So Joey's deal blade friend of ours.

00:50:35

Speaker

He yeah he has Festool battery holder, 3D printed battery holders. So I asked him how much they were and he told me and I said, all right, cool. He goes, I don't have any in the store. I was like, all right, cool. Let me know. So tonight he emailed me the file for the battery holder and said, now you got a reason to buy a 3D printer. I was like, man. I mean, you're already saving money by not paying for somebody else to make those.

00:51:01

Speaker

but They're, I mean, they're surprisingly, um, you will find uses for it. Like, I mean, my, my stuff is mostly, you know, toys or whatever, but like they're, like they are a legitimate help in the shop. I don't know if you guys have saw like, uh, Chris from full steam designs. I've made a a pretty legitimate, uh, pocket hole jig from the 3d printer that, I mean, appears to work as well or better than it's one that uses it with his router and a drill bit.

00:51:29

Speaker

And it seems to work as well or better than the, uh, than the Craig jig, because it it gets a lower angle to the screws. Uh, so it's less likely to pull. It seems like it's a little bit stronger. Uh, the connection, uh, three printed part, you know, he literally iterated. Another product. Right. Yeah. Yeah. I mean, there's, but what you know, it doesn't take very long on Instagram going through and seeing all the various hobbies.

00:51:59

Speaker

Including 3d printing in their hobby. It is it is just it It can be a tool in of itself. It is my hobby and so it's this is the end for me, but for You know for woodworkers. There's a place To make things I mean if I mean fixturing jigs and stuff like that you can print one off specific Like jigs to help you with glue ups, you know hold their complicated shapes or you know if you're doing segmented bowls and No problem to print the jigs to help you cut out the parts for segmented bowls and you can get it Get all your angles perfectly precise. All your segmented bowls go together better, you know, there's me yeah I mean any hobby you can think of There is a place my wife will do embroidery

00:52:47

Speaker

All of her embroidery floss is now in a a case that I designed with little holders that fit in it that I designed. And those holders chuck into a drill, and she can wind her floss on it with a drill instead of having to do it by hand, yeah all 3D printed. So i mean embroidery, or you know yeah has a place like 3D printed. So every hobby. Because you're just making one-off specific

00:53:16

Speaker

tools that no company would manufacture it because there's not enough use case for it. Or if they do manufacture it, it would be prohibitively expensive. There's only five people will ever buy one. Right. But you can just make it. Yeah. So what's my sister does that diamond. It's like, yeah, whatever. Yeah, my wife does it. Yeah. And actually Vincent printed a thing that she can scrape her

3D Printing in Various Hobbies and Workshop Maintenance

00:53:43

Speaker

little pellets into and it funnels them back into the container.

00:53:47

Speaker

Okay. Yeah. It's like a, like a Lego shorter for little tiny diamond pieces. there yeah Yeah. I mean, that's something it's, yeah, it is a, it can either be, it can either be the hobby or it can just be ah a tool in the toolbox. How, how are they? Um, like I see like the A1 mini is no case at all.

00:54:10

Speaker

How, like, will they survive in a wood shop with, with, with dust and stuff, or should they be inside in a closet somewhere inside? I wouldn't, I wouldn't put one in a, like a wood shop, like a spare wood shop. Like, you know, if you have a clean side of your shop.

00:54:24

Speaker

But yeah, I would like it. Yeah. That's that's off my laser. Yeah. i would just and the Main reason I wouldn't recommend it is because anything on your build plate that prevents a good connection between the plate and the plastic is a problem. Like your greasy, dirty fingers.

00:54:43

Speaker

are enough to like they're they'll put down enough of a layer of oil that will when it's hot, it prevents that bond between the plastic and the build plate. okay Note no to self do not spray WD 40 on a build plate. Now, I mean, I've got my x one carbon, it's in my wood shop. And I do cut wood in here. However,

00:55:09

Speaker

The X1 does come with the full enclosure, so you can just shut the front door. yeah However, that is also inside of a cabinet. well um I designed a cabinet for my first 3D printer, which was a resin printer.

00:55:28

Speaker

that I've since got, I got rid of it after I got the bamboo. But you can't get sawdust in your resin because that's just going to be a shit show right there pretty quick. So i I made a cabinet that's got, you know, doors on the front that swing shut and close and keeps a small enclosure that is dust free. Now, most of the time when I'm printing, I'll leave those doors like open a few inches in the front so it doesn't get too hot in there because I'm using the the the plate that needs the heat on the heat bed. So it gets toasty in there and I don't want things to get too hot. So I'll leave those doors open if I'm not making sawdust.

00:56:18

Speaker

That way they get a little bit cooler basement air to circulate in there. But I mean, if I'm going to fire up the table saw or the CNC or even the band saw, which is right next to it, I will shut those doors down. I'll shut the carbons front door all the way and I'll shut the cabinet doors in front of it. So that's and not dust proof 100%. It's not clean room, but it it screens out, you know, 95, 8% of it or something like that.

00:56:47

Speaker

And a little bit of common sense goes a long way. I mean, it's, it's a computer component and you're dealing with either screws or linear rails. So you're talking about bearings and the whole point is you're wanting stuff to, to, to move smoothly on a track. I mean, just like the CNC, if you don't, like, I guarantee there's a lot of people that that have problems with their CNCs that some of the problem is.

00:57:11

Speaker

They're not keeping them clean so that the accesses can't move smoothly and causes problems. You reviewed it. Got to clean out your ball screws occasionally. I, uh, I literally just replaced, uh, linear rails guides. Cause I just, they just got eaten up, just destroyed them and, uh, not a fun job. So take care of your equipment. Yeah.

00:57:35

Speaker

So, i and you know, it's a little bit, a little bit goes a long way. I usually print cool and I print slow. um So my machines, some people didn't believe me, I have over 10,000 hours on my first X1 and I've done almost no maintenance to it. Like definitely have not done all of the recommended maintenance. Certainly haven't done it at the recommended intervals. But I also, like it makes a difference that I print a little bit cooler than normal and I print a little bit slower than normal. So I'm not stressing out the parts as much as a lot of people do. So it's my everything has lasted longer for me. I've been lucky. I'm really envious of like your, your lab, your laboratory level setup. Like it's just beautiful and clean and

00:58:26

Speaker

Like a lot, a lot of the serious 3d print guys and gals, you see, like they have these print labs that are just like, yeah, it was, this is a new development. Um, the, the room got, cause I had some work tables and then every surface had a printer on it. And it became where I had a ah room full of tables and no flat surfaces to work on. Uh, and I had.

00:58:50

Speaker

Print I have just rolls of filament stacked up on the floor because I didn't have enough space for them So I've recently redone the whole space For that reason, but yeah, it's it's it's been a lot of like, you know It makes a difference mental health you walk into a space everything has a stress. It's sure you know if it's more conducive to To work, but you also don't see what's over here which is all of my half finished projects so that need to be either glued together or painted or rub and buff or or you know assembled so yeah it's not all web clean

00:59:28

Speaker

So are you, so are you wifi to these printers or Bluetooth or something? So you literally just pull down a menu and select what printer you want to send a a job to. Yeah. So you don't have to have 10 computers in there. Absolutely. Yeah. Yeah. Yeah. Nice. Yeah. The first one, like when I first got it, you'd had to physically carry an SD card over and some people still do that because they want, they don't want their stuff going to the cloud. Like, you know,

00:59:55

Speaker

I don't care, particularly that China sees my articulated dragons because yeah whatever. But like I can understand some people, you know if you're if you're designing or printing something and you have a proprietary designer, you have something that you want to protect, your you know you may not want that going into the cloud and and yeah sitting it somewhere else. so i mean You can do both, but for me, it's...

01:00:18

Speaker

Bamboo is a Chinese company and we are sending things up to the cloud through their server and back down to our printer.

Innovation and Cultural Shift in 3D Printing

01:00:29

Speaker

I mean, I'm not saying that's sketchy. I'm just saying that, I mean, if if I had, if, if I was a company and I was printing some fancy proprietary design that we'd spent many, many thousands of dollars developing, maybe I would put it on an SD card and walk it across the room myself. like that's you know they They have recently, very recently he started implementing some policies, Bamboo is what I'm talking about, have implemented some policies that have not gone over well with the 3D printing community.

01:01:03

Speaker

like the The community itself has kind of an ethos of like openness and feeling like, because it came from open source, it was like 3D printing technology didn't come from a company, it came from hobbyists, and now companies have monetized it. And so there's the ethos has always been open source,

01:01:27

Speaker

transparency and bamboo has kind of started the instantification of that. They've started to close some stuff down and there's been a lot of pushback. Um, as of right now, then like sending stuff through the cloud and having that stuff, like to me, that's, I've got bigger stuff to worry about. Like, you know, is it a concern? I can understand where you would be concerned, but I've got other stuff that I'm way more concerned about.

01:01:56

Speaker

Right. I mean, especially when it's a flexi dragon that you paid some other guy that designed it so you can use it and sell it. And then or if I downloaded the model from their website, it's already uploaded to say it's already there. It's already in their library. They already know what you're printing and they know what you've done.

01:02:23

Speaker

nice So, I'm sorry, go ahead. Well, I was just going to say, you know, there's, there's a lot of talk about, you know, selling things that you've downloaded and paid for the rights for. And there's a lot of talk about how you can use these things to prototype and make new models without having to play with, you know, China and injection molding and But the thing I think sends to get glossed over is how many people are printing actual products and they're doing their full manufacturing on these printers. I mean, when you look at it, like, uh, Joey is printing these, uh, 3d printed battery tool holders for Festool. He's printing them. He's selling them straight to consumers.

01:03:20

Speaker

and he's kicking them off his printer and he's selling them straight to people. He designed a product, he marketed the product and he's selling it straight to people right off his printer. And ah seeing as everybody's clearly been listening to making it recently, Bob has been selling um some 3D printed camera mount that mounts off of, yeah It mounts off. I think it's the, the, the pole that goes in your, I dunno, he's got some sort of a pole. I don't remember what the hell he's got going on, but he's got some camera mount that he designed that he put a lot of work into. And he's been talking the last couple episodes about the fact that he put this on his website as an actual physical product.

01:04:09

Speaker

And he's been selling them. He'll, he'll, he'll push the button. When he goes to bed, he'll get up in the morning. He'll pull five products off of the bed and he'll go over to the computer, print some labels, put them in boxes. And he's mailing these things to people. And this isn't, this isn't just about the, the.

01:04:32

Speaker

The prototypes, everybody focuses on prototypes and prototypes are great. I mean, don't get me wrong. It's a great way to prototype an idea for really cheap. But once you've finalized your design, this is an actual practical, affordable manufacturing system that you can sell. You can just create an entire product line, hit i've really got these things.

01:04:59

Speaker

And sell them to people if you I mean it doesn't if you understand how the the printing process works And you're paying attention to the the strengths and weaknesses of that That technology like ah you know the 3d print like a 3d printed object has certain but advantages and certain weaknesses compared to injection molding. There's things that you can do with 3D printing that you can't do with injection molding. There's things that injection molding will do that 3D printing doesn't do. As long as you're taking that into consideration and designing around that,

01:05:36

Speaker

there is no there's no real reason why a 3d printed product product can't be just as good as a quote unquote like traditionally manufactured product so that's what exactly i'm talking about it's it's changing the idea of small scale boutique manufacturing i think is going to you know they always talk about bring manufacturing back to america Well, I mean, that doesn't we're doing it it doesn't necessarily have to be a massive mill or a huge factory but because you can, you know, one factory might employ a hundred people from this one town, but if we can teach people to create things themselves, like you can have 10 times that many people having legitimate jobs, manufacturing things in their own homes.

01:06:30

Speaker

as their own business owner. Like you can bring manufacturing back to America and it doesn't have to be a corporation making the money. But you can be the little guy. Yeah, our great, great, our great grandparents, you know, traded milk and candles and blacksmithing and stuff like that. We're going to be trading and selling 3D printed objects, CNC created objects, laser cut objects, oh you know, making products for people and and you can And you can competitively make products because everything that I do, there is no middle man. I'm direct. yeah And like so I can charge a legitimate amount for my time, my materials, my inflexible property, charge a fair amount, and I can still do it for a reasonable price because I don't have a whole corporation. Now, there's disadvantages, like you know having a whole corporation, there's stuff that comes along with that.

01:07:28

Speaker

but there's also the overhead of having that that has to be factored at. So like, you know, you can do volume or you can be lean and both have their advantages. You know, so it's, it it it is absolutely a viable choice for not only for people, but I think as a, as a country, it is a viable step for us to take that. I think we need to put more focus into.

01:07:56

Speaker

But that is how you bring manufacturing back to this country. Or one of the ways. I believe that'll preach. Sounds good to me. ah So I've got a question and it has a lot to do with looking at these racks full of filament over your shoulder here. Um, these are all well open to the air in your room. And I'm curious if you've got any systems or solutions for the moisture problem, you run dehumidifiers or do you have dryers? Do you use that?

01:08:35

Speaker

Um, so the trick is, uh, live somewhere that's not terribly humid and have an air conditioned house. Cause that's all I do. So you got, you got one of the two.

01:08:48

Speaker

Legitimately, I have rolls of filament. that I have my first roll of filament that I ever got. It's still on the rack right there. It came with my very first printer and I've just never used it all because it's not that good. but I just don't want to throw it away because I'm nostalgic like that. I was going to say now it has meaning. But yeah, but it would if I threw it in this printer over here, it would still print.

01:09:12

Speaker

I've had a handful of rolls get brittle and snap and break and and and explode, but literally over the thousands of rolls I've bought, I think it's happened to me twice.

01:09:28

Speaker

I've probably lost a little bit of print quality on a few of the rolls that haven't they've been out for a while Some are worse than others But I would say by and large for PLA in an air-conditioned house and I don't live in Louisiana Uh, I've been, uh, I really, I

Filament Care and Operational Efficiency

01:09:48

Speaker

think that a lot of times people are, you know, every time you go to Reddit and there's something wrong with the print, I'll dry your print. It's just because your film is wet. It's that's sometimes it's the problem, but it's not always the problem. I think people try to make it like that is every time. I don't think it's.

01:10:04

Speaker

You know, and again, it's certain filaments or worse. Certain filaments are more hygroscopic than others. So they're going to attract more moisture. TPU, i'll I'll dry it before I print it every time. PETG, if it starts getting stringy, we'll dry it, we'll make a difference. I don't know what you say, dry it, let's dry it. Okay, so it basically, it's it's ah you're putting it in a heated chamber and it helps dry the moisture out of it.

01:10:31

Speaker

Because like there's a ah machine you buy to dry filament. I mean, you can you can you can buy a machine and you can buy a food dehydrator for free. You can go to the Goodwill and get a food dehydrator. It'll work just as well. You just want blowing warm air over it really is all you're doing.

01:10:48

Speaker

I mean, technically, if you're careful, you could do it in your oven, but I wouldn't recommend it because of you know plastic can be probably not great. If you have an enclosed printer, most of them have an option or you can get code to where you can, it'll just heat the chamber up and you can just... So basically you just put them in a warm environment to drive some of the moisture out relative does that take hours or yeah yes? usually ridiculous I I was just looking at this last week about whether I should get a dryer and I saw somebody say oh well you can just dry a spool in the x1 because it's got the full enclosure on there you can I

01:11:30

Speaker

You can stick it in there and it apparently there's a setting for it somewhere that you can go into the tools and tell it to dry your filament. You put a roll in there and lay it down on the bed. And then I think you get to come back after six hours and flip it over and then cook the other side for another six hours. But I mean, that gets you one roll dry and it's 12 hours.

01:11:55

Speaker

Well, you know, I think that's more for, you know, for people that maybe have a tool and they only use it occasionally. You know what I'm saying? yeah I would say um I print once a week and I know I'm going to need to print this at the end of the week. I can go ahead and dry my roll. But for someone like me who's who's running six machines 24 seven, I wouldn't tie one of my machines up to dry. I'm going to go spend $40 and buy a purpose made thing. This seems to be,

01:12:19

Speaker

Listening to you to two hardcore printers like this seems to be a very don't get in a hurry Yeah, it's it's not a fast. Yeah, there's yeah, it's yeah it's a i like yeah But it is like the machines have gotten to the point where you know You're probably at the point where you can have your CNC running like, what's the word I'm looking for? You don't have to babysit it all the time. Oh, I've got a camera. I leave it all the time. But like, you know, for a lot of people like... Edit that out.

01:12:57

Speaker

But i mean ah for most people, they'd want to stay with it. you know But in 3D printing, earlier, like you know the back in the day, like I think a lot of people are concerned about fire and stuff like that. And it is a machine. yeah like It's a heater running in an enclosed space. There is a danger. But like mine is a tool that works for me when I'm not around. So yeah, they just they run pretty much all the time.

01:13:26

Speaker

and i I find them much more likely to self-destruct than they are to be outwardly destructive. They're more likely to blow themselves up and just short and stop working than they are to like catch your room on fire.

01:13:43

Speaker

I mean, I won't say it's not possible, but I'd say it's extremely unlikely. Yeah. And to your point out, like the, but that's why you see basically everybody that really gets into 3d printing, even if they think they're only going to need one, always end up, I thought one was also, you end up with like six is because it isn't a instant gratification.

01:14:04

Speaker

Right thing. It's it is, you know, every one of these prints that were going behind me was probably a full day. Yeah. Yeah. So, you know, it's especially if you start doing the multicolor stuff, it's slow. Very slow. So that blue, it looks blue on the screen next to the yellow on there. I guess it'd be the third one. That thing looks like it's flying. All right. Which one? No, that one's not. no Those aren't running.

01:14:31

Speaker

um know the other one over that side that one yeah yeah no they Yeah, they're fast. I mean, they like compare to how they used to be and back in the day. that's actually Mine actually runs slower than most people that you see off that machine. I find that like and cook it for me,

01:14:52

Speaker

print quality is more important than speed. Yeah. Chris the same way. I found that if I slow it down, I don't have to make it crawl. It's still there way faster than the last generation of printer. But yeah if I slow it down just a little, I found that a lot of my defects disappear. So it's worth it to me. I thought they were just like cruises. Not anymore. Yeah. Well, that's what I was going to ask, you know, like it It really, but not bumps, well, pissed me off, straight up pissed me off. Like when you first get into CNCs, like all anybody wants to talk about is how fast you're running it. And it's like, I don't need to run it. Like I run my average speed is 100 inches a minute for cutting, you know, and people are like, well, you can go 600. I'm like, I don't need to. Why do I need to? Why would I stress the machine, you know, and break bits and

01:15:43

Speaker

yeah Right. You know, I don't, and i'd and I would rather have a better cut quality. I don't have to sand for two hours after you're done in 20 minutes, you know. Exactly. what I mean, if, if you're making say drawer fronts and you've got a contract to make a thousand of them.

01:16:00

Speaker

Yeah, now you need to run fast. That's when you try to push things. And that's why people are so driven to see, well, how many parts can I get done today if I crank this thing all the way up? And that's that that's the reason why people didn't succeed with belt-driven CNCs. Yeah. Because you can't do that shit. They were just getting so much flatter. If you've got a Shapeoko and an older one with belts and a trim router on it, you can't just barrel around in circles at 900 miles an hour because it's going to break shit. It's going to stretch the belt. It's going to jump notches on the belt.

01:16:45

Speaker

and the router can't keep up. so yeah it It was invariably a more, it's a more sound investment for me to have a second machine and both of those machines running slower than having one machine and balls to the wall as fast as I can get to go. Because like I'm going to get a, like that investment of the second one is going to give me a better print quality, less post-processing And I can get like, you know, so it may take two machines to get the same amount of output, but that output is going to be better. Yeah. if you're not yeah if just and There's, you know, you've got to find that breaking point. Like, yeah where do you start? Like go as fast as you need to, until you start seeing the negative side of it. You don't need to go any faster than that. Yeah. yeah to To put this in CNC sawdust terms, that'll make perfect sense to you.

01:17:44

Speaker

yeah If you cut out a part in 15 minutes and then you have to go sit down on the workbench with your Festool sander for another 10 or 15 minutes, you've got 30 minutes worth of work into this part. But if you slow it down and you tweak your toolpaths to be just right, you can pull apart off of there in 20 minutes yeah or 25 minutes that you don't have to sand the damn thing when you're done because it's beautiful. You saved even more than that though, because you've got to think about like if if the machine does all of the work and you were free, your time was available to you for something else. yeah what are like if it takes Even if it takes the same amount of time, but if you're physically having having to do something for half of that time,

01:18:35

Speaker

It's not the same amount of time. Yeah Because you can get something else like your time

01:18:44

Speaker

And it's exponential. Exactly. Yeah. Yeah. Yeah. 100%. And, you know, to your point, you know, add another printer, if you're not using real money, you might, why not add another printer? You're just using printer money. My wife has definitely been more, she's stronger. like That mindset is more natural to her than me. Like investment into the business. Like investment in the things that make money.

01:19:12

Speaker

like that's a That's a, that's a good thing. You got a good wife. Yeah. Like it's like when I first decided, this so it all started like the whole making thing. I was, we wanted crown molding in the house and I, the only thing like I, there's a partner I cannot stand to pay somebody else to do a thing that I could do myself. And I mistakenly think I can do almost everything myself. So I would say that's the only thing I hate worse than mowing the yard is paying somebody to mow the yard.

01:19:41

Speaker

yeah So I was going to put up crown molding, which led me into a rabbit hole of how do you put up crown molding, which turned into woodworking, which turned into, and then I mean um just came to her. I have to pull up nothing. I was not a maker. I didn't have, and like, we didn't even have a craft room, nothing. I said, I think I should buy a laser. I think we could make, I think I could make products off of, I think we could make money.

01:20:04

Speaker

And no hesitation. And it was way more than we could have we could afford when we got it. No hesitation. I'll get it. We'll figure it out. it will not And the laser never paid for itself, but it led me to completely

Entrepreneurial Ventures and Early Adoption Benefits

01:20:20

Speaker

change I mean it changed my life and it also did lead me to this and I have probably made enough here to have paid for it so technically it did pay for itself yeah just in a roundabout sort of way but like yeah she had no hesitation and if a thing's gonna make you money invest in it. Yeah good deal. My laser didn't pay for itself so I bought another one and we're still on the same boat.

01:20:42

Speaker

None of my stuff is paid for anything, but I've never focused on sales. So that's, that's not true. That's not true. These, this equipment has, we may not have taken the money and paid it off, but these things have more than paid for themselves. I love it. I'd love to have one of the cyber lasers. I see how my friend Austin. He's doing some super cool stuff. out there I'd love to have one. Yeah. This is, I've got the fully enclosed thunder.

01:21:10

Speaker

yeah Yeah, that's same one Austin's got, except he's got the he's he's got the one with actual horsepower behind it. Yeah, this is 50 watt rakis. I think he's got the 150, but it's the same machine. I'd love to get more oomph and a higher electric bill. That's the only thing that kind of makes me wish I was had put more

01:21:35

Speaker

into like the the okay so you get jealous of the people that get sponsored and get the the free stuff and like you it's easy to forget the amount of work that they put in like they didn't get the stuff for free yeah they pay for it with their time like everything that like you know awesome or like you know a friend morally or any of those any any of the stuff that those guys get yeah they're paying for it they're just paying for it with their time so but like It's easier for me. like i would I'd rather pay some of them in my time than with my money because money's real and my time's not. Apparently, somehow that works. so but yeah like i'm I'm jealous. I wish I had done more. with the Plus, getting this stuff early is also really cool because you know yeah you get it for everybody else. There's something to be said for that. yeah so

01:22:23

Speaker

Well, and you can make actually, I was just talking to a friend tonight. He's, he's looking at, uh, he borrowed or or a friend of his loaned him a laser, the laser rust remover. Cool. Yeah. was Great. Crazy Watts. So he's looking at buying one and he's like, I don't know. You know, they're like, he, he said they're like 12 grand. And I said, he owns a custom body shop. This guy's amazing. And his wife is a laser, you know, and stuff. So they're, they're, they're, they're hustlers. They're, they're amazing.

01:22:52

Speaker