Become a Creator today!Start creating today - Share your story with the world!

Start for free

00:00:00

00:00:01

6 Chris Raley of Route 9 Signs

Chris is an amazing miniaturist who uses his laser and Bambu printer to reproduce classic neon (and other) signs.

https://www.instagram.com/route9signs/

Things of the week:

Chris: Trains and train traveling

Al: Therapy and maintaining your mental health

Jeff: Suspended 3d prints (3d string art)

Patreon: http://patreon.com/digifabricators

Discord: https://discord.gg/hHp8Sv7vt4

Recommended

Transcript

Introduction to Digi Fabricators

00:00:12

Speaker

damn Hello, and welcome to Digi Fabricators, the show where we learn how makers and artists use their computer-driven tools for fun, art, and profit. I'm your host, Jeff Stein, AKA a weird guy. And with me is my talented but humble co-host, Al Schultz of New York Woodworks. How are you doing, Al? I'm doing wonderful. Thank you very much. Awesome. Good to see you today. It's good to be here.

00:00:43

Speaker

All right, let's fire the official podcast disclaimer off so we can get started.

Disclaimer on Expertise

00:00:49

Speaker

Even though we pretend to be experts on the internet, I would like to point out that neither of us have any actual training and are just guys winging it in our shops and learning as we go all advice provided is based on our personal experience and possibly inaccurate assumptions and is worth exactly what you pay for it if listening to this show causes you to take out a loan to buy new and expensive digital tools you may tell your spouse that it was our fault

00:01:14

Speaker

do so at your own risk so today's guest is a famous artist who's been featured in newspapers podcasts and even has his artwork artwork featured in a museum his miniature artwork is a sign of times gone by despite using the cutting edge of technology to create it welcome to the show chris rayley from route nine signs good morning gentlemen it's great to be here with you thank you for asking me to be part of your show

Guest Introduction: Chris Rayley

00:01:46

Speaker

good morning sir thank you for being here and i've seen some of your prior guests already and i'm um just here to say i am not worthy but thank you so well there's a lot of people that would disagree with that well yeah me

00:02:03

Speaker

i'm i'm kind of fanboying out here today yeah well no it's it's it's great to be here i'm i'm ah an admirer of of both of you your works jeff um little more familiar with you for you know over over the years but yeah you both are extremely talented and i'm honored to be here with you well why don't you give us a quick who you are kind of stuff you do and what kind of tools you own to make that happen okay um my name is chris rayley i'm an artist a maker a miniaturist primarily

00:02:39

Speaker

um i specialize in recreations of kind of iconic signs not necessarily neon signs but anything that you know any business or hotel or or whatever that has ah kind of a unique sign might be something that someone wants ah miniature version of in their home and so i i specialize in that ah there are a lot of miniature artists who are kind of generalists they'll make buildings and signs and just like a little bit of everything i tend to kind of focus down just on

00:03:12

Speaker

primarily on signage and there are a few people that are doing it now but when i started doing it about six years ago there weren't there wasn't really anybody else focusing on signs like i do and i i don't like a crowded workspace you know so i was i was pretty happy with that i thought about getting into woodworking i want to do fine woodworking but there's you know first off the the facebook groups the the facebook like boxmaking groups that place you ask a question and instead of getting an answer you get yelled at so

Journey into Digital Fabrication

00:03:45

Speaker

i gave up on that pretty quick and just kind of decided to find something that i could do on my own um as far as the digital fabrication stuff i started out making kind of like making jewelry from autism awareness jewelry i would make because my son my son has autism and so i learned how to use a laser cutter back then probably twenty thirteen twenty fourteen i had ah ah k forty the notorious ah amazon four hundred dollars gonna burn everything down laser

00:04:17

Speaker

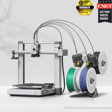

um had two of those actually and i learned a lot there's there's so much you can do with a little machine that has like no safety features at all so i yeah i learned how to use a laser with that and um currently i'm using i have a glow forge pro i'm sorry glowaf forge plus it's my second one of those um had that been using gofor for about four years i have a bamboo x one carbon with a couple of ams units so i can do up to eight colors of printing

00:04:48

Speaker

i have a bamboo a one mini um that i also use um i have a vinyl cutter um basic woodworking tools so that's kind of kind of where i'm at like what i what i do and and the primary tools that i use so what do you using the most i mean you're you're making small replica signs which are you know desktops say what twelve eighteen inches tall twenty four generally they i try to keep them about

Challenges and Solutions in Miniature Sign Design

00:05:22

Speaker

about eighteen inches i don't like making them too small um one because when you want to charge somebody x amount and it's a little tiny thing versus oh it's fifty percent bigger you you know you can you can can play with that a little bit but i like making something that's um generally about eighteen inches is kind of like where i i peek out and the reason for that is when i first started using my glow for the bed size is like nineteen and a half like the the width of it so

00:05:53

Speaker

i was making pieces out of wood like stacked layers of wood when i first started so the glow forge would only go about eighteen nineteen inches so that was kind of like my my limit i've made signs that are four feet tall i've made um the stardut sign i made earlier this year was about three feet tall but i've learned how to um you know kind of if i make something big i can piece it together but generally i try to keep things within the constraints of my machines like um

00:06:24

Speaker

the the bed on the bamboo the carbon the printing print bed is basically ten inches by ten inches and so i tried to my biggest component for any sign i try to keep it within that limitation if it's something i'm printing so yeah about eighteen inches um give or take and then amazing how the the constraints of our specific tools limit how we make our art based on what what fits yeah but you know it really has is taught me how to be

00:06:56

Speaker

little more you know creative like that stardust sign that i made and that i donated to the museum in las vegas the the top part of it is about sixteen inches wide so i had to print just the top of that start assign is actually four different print that i peace together just to make like front and back left right so it's like four and i use like the almost the full size of the bed so you know i've learned it's nice to be able to do everything as one piece but it's also nice to know how to expand to go beyond the limitations of your machines if you have to

00:07:31

Speaker

and know you' you talked about how what's that go ahead go ahead you're building so you're building in layers you're building like a carcass and then adding details to make yeah as ah as it grows right right and like you know sometimes i'll i will make a piece it's just all three d print something that's just kind of like the support like the main like the the bones of it and then i'll go in with the laser and do the detail stuff or i will then use a ah finer setting on the three d printer and and do the detail

00:08:02

Speaker

work i don't i don't you't it's not usually like a one piece print i never really do that it's like that if you saw the sign i made couple months ago it was um from japan it was sign from mosaka um had a rusty channel had a bunch of light bulbs along the bottom that was probably probably i would say about three hundred different individual printed pieces all in ah eighteen by ten inch peace just tons of individual

00:08:33

Speaker

printed pieces so so do you when you start this process whatever it is you do that or whatever and you see a sign that you're like oh i want to make this sign what where do you go from there ah do you just acquire every photograph you can find from google images are there scale programs you're running to say i want to make this twenty inches tall or do you just make it aesthetically pleasing and it fits and feels good yeah i um generally the sign selection most of what i make is is commissioned

00:09:07

Speaker

so generally the client is the one who's who's picking the the topic the subject matter and at a bare minimum i need one photo i can't i'm i'm not a graphic designer i can't create something all on my own it would look like crap um because i've tried but um but i scour i there are a few databases and i love google like street view google images and there's there's some archives that i that i go through and i try and find

00:09:39

Speaker

as many photos of the sign as possible and not just straight on of photos of like the face i try and find a shot like if it's ah if it's a motel sign i try and find ah an angle from the street so i can see not just what ah what the sign looks like on front and back but what the sides look like how thick the sign is because when you when you turn it and you look at it face on there is some depth to these signs and and being able to see it from the other direction really informs how it looks when you look at it face on so i try try and find

Using Google Street View for Design Accuracy

00:10:12

Speaker

is many different angles as i can some places you can find some of the artwork online if it's a big chain like a holiday inn you can find the artwork if it's a disneyland thing you can find the artwork but some of them you i just have to just kind of draw it all from scratch and it's literally just you know you got your little little curves and your your points and you just you draw a line and you just shape it and you you do it until until it looks like what you're what you're wanting it to look like but

00:10:43

Speaker

um to get the proportions right if if it's a sign that i can find like on street view i will go one of the things that i i learned early on is a perspective like if you're if you're looking at if you're ten feet away from a big sign and you're looking up at it the perspective is way different than if you're two hundred feet down the street looking at it the view two hundred feet to view from two hundred feet away gives you a better look at actually like the proportions of the sign so i will oftentimes go

00:11:14

Speaker

on street view and get as far back as i can on street view it doesn't need to be a clear image it doesn't need to be the entire sign but it gives me an i it gives me a better look at what the relationship is between all the elements it's not skewed by perspective because if you're standing at the base of the sign the top is you know thirty feet away but the bottom is only five feet away so you're going to get you're going to get some you're you it's not going to work so i try and get as far away from it so that i can i can tell oh this this is these are the relations to the pieces and then

00:11:48

Speaker

really my modeling is it's going back to when i was doing my jewelrymaking i bought a silhouette cameo machine probably about ten twelve years ago and i so it's it's a vinyl cutter it's like a craft level cricket but like like like a cricket like a cricket um but so likey what cameo and i started doing design work when i would use it i would use their their design software

00:12:19

Speaker

and when i started using a laser i needed svg files well i found out that silhouette studio the software for my vinyl cutter if you upgrade to the business edition for a hundred bucks you can export svg files and so i to this day still model everything that i make i use the vinyl cutter software i use silhouette studio and i it's all but essentially it's not a black and white image it's a it's an svg

00:12:50

Speaker

but to somebody who doesn't know what svg's i just say i i draw it all in black and white images and then you know transfer transferre it into something like tinkercad because i don't know how to use i don't know how to use what is it what's what's the one that i paid three hundred dollars to to um bob for my like to make stuff fusion i bought the fus i bought the i bought the fusion class and i still't know how to use use and but um so it's it's it limits me i have to do a lot of stuff manually in that program

Design Process with Silhouette Studio

00:13:21

Speaker

but i know how to do it whereas if i open up ah fusion or shaper whi any of these programs <unk>s like i don't even know where to start so it's it's it's very interesting you say that i'm finding now that we have had a few guests on the and don't want to say old but the more experienced we are as makers the the more experienced makers like the ones with gray hair like us yeah i mean jeff is jeff jeff's a unicorn but um i also do all my design work in

00:13:53

Speaker

i have verick aspire which is my first my first cnc software so it's what i learned it's what i know um tried i've tried fusion i've tried i i just it doesn't make sense and people who see me design in and aspire are like why are you doing that that is the most archaic thing and i'm like well it makes sense to me right well what i like what i like about it is i'm finally at a point with with my software that i use and the machines that i have is that

00:14:24

Speaker

if i draw something and it's what i like is i can i can draw it out on my screen and say i have a fifty by fifty millimeter just a black square if i print it on paper it prints at exactly fifty millimeters if i throw it in my laser it will cut exactly perfect or if i three d print something everything and there's no i don't have to and don't have to change anything like if i i do a lot of where i'll print something with like a channel and i'll i'll insert

00:14:56

Speaker

a piece of acrylic and it needs to fit perfectly and my machines and my software and everything it all just work really well together so it's not broken it's not perfect but it's not broken and and everything that you've seen me make has been made using those and inappropriate software you know yeah those programs and every once in a while i'll have to drop down into inkscape to to export like if i'm gonna send something off to um sendcut sand if i'm going to have some metal cut for a piece

00:15:28

Speaker

it needs a dxf file and so i'll make my svg in my low primitive vinyl cutter software export that to inkscape turn it into a a and whatever the file it is that send cut send needs and then send it off to them so i do have other other programs but it's real i couldn't do anything else in inkscape that's about all the only thing i know how to how to do it's just this other program it's like second nature the silhouette studio is you know i use that more than anything

00:16:01

Speaker

i know i know it really this is a really good ah um'm glad i'm glad you said this in this line that's happening because it's very good to point out to people that you don't have to have the biggest best computer the biggest best software the biggest best machineen the biggest best whatever know insert your biggest best thing here you can do this with what you have and you can just figure figure it out um you know i work ah subcontract to a so ah locally good friend mine

00:16:31

Speaker

and and and his software packages are thirty thousand dollars yeah yeah and it's like it's like wow that's amazing that's great i don't understand it and that would be such a waste of money for me right but he but but he sends me files to cut from his twenty five thousand dollars software and i import them into my twenty five hundred dollars software and they cut exactly the same right right exactly and if i if i were doing things if i was doing like the carving like that jeff is is doing with the cnc

00:17:02

Speaker

i would need something different but really man um if you see something that came from me that is not a flat plane in one direction or or another um you know that's something that i've had to go into like to tinkercat like if i have something like a ball or a sphere or a bowling pin or something like that then i have to kind of lean on other stuff or i have to try and find existing models and modify them but generally speaking and that's the good thing about most of these signs that i recreate

00:17:33

Speaker

they were made in sign shops that have a lot of flat they were made from flat stock to begin with and most of what i work with is is flat stock and if it's not flat stock it's a it's something that i'm three d printing that's like a box or a rectangle or a cube or you know it it's something that i can that has like a flat side that i can that i can extrude into whatever shape i need and an eo it's um yeah it's i'm lucky if i were and that's that's part of the limitation though because i've had people say oh can you

Overcoming Physical Limitations with Creativity

00:18:05

Speaker

make this for me and it will have like a statue it it willll have ah like ah a pig like ah like an actual pig and like ah for a barbecue place its someone ah signot molded this pig in fiberglass and unless i can find a three d model online that close to that i just have to tell them no because i can't model a three d pick like that i can't if if it's if it's twodi dimensional and the paint job's not too complex yes i can do it but so that's where i that's where i'm i'm

00:18:37

Speaker

limited is i can't do there are certain things that i just can't model and certain things that i like certain paint jobs i can't recreate and that's fine i've been i've stayed busy for five years not doing those kinds of things so lucky wow i did jot down another question here quick um'm sorry jeff please go ahead no it's okay i was just gonna say that all artists have their that they're high spots and their're low spot and modeling

00:19:09

Speaker

modeling weird three-dimenional organic shapes is it's its own level of art in itself i mean you you basically have to sit down and master blender or something like that right get and that's that's one that's beyond me too i do lots of straight edgege modeling extrude from svg kind of modeling yeah that's what i do but yeah the the organic stuff that's that's rough

00:19:43

Speaker

that's that's ah that's a whole different skill set so and one of the things that i deal with and i don't know if i've ever touched touched on this i've kind of mentioned it and when i've done other you know the podcasts that we've all listened to over the years but i have vision issues my um i'm not blind in my left eye but i can't pardon my language can't see shit out of my left eye like dead on the my peripheral is fine but like if if you're to if you were to hold your fist out like arm lengths and hold your fist out

00:20:17

Speaker

about an area about the size of your fist and for out arm extended i have a spot about that big that's just completely scrambled it's like a kaleidoscope it's moving like this so when i look directly at something with my left eye it's just kind of chaos my retina is damaged from a lot of i had a lot of issues about ten years ago and in my right eye i ah with a blaer and a yeah yeah yeah had some near had some near my near um

00:20:48

Speaker

so it's right it was right around that time no it's because i was there i was very nearighted as a kid my eyes are all checked up but um but my right eye out outside some retina damage and i don't see straight lines everything has a little bit of a curve to it like when i go to pick out lumber at home depot i can't just hold it up and look at it i have to like lay it down on the floor and get down like okay i don't see any daylight on this one okay this this two byf four is straight um and so being being a miniaurist being a miniature who has no depth perception and can't see

00:21:21

Speaker

straight lines limits what i can do i have friends um i ah a friend who makes things out of paper and milan hers milan eat zombie is her is her name on instagram she makes these just super elaborate little things out of paper like she made a scissor lift that you can like actually lift up and like like you could put two people in and go up like to the ceiling of ah of gymnasium and change lights a lift like that made it out of paper and it's it's

00:21:52

Speaker

you know when it's when it's down in its low position it's only maybe an inch tall if that and it stands up several inches but it's all paper and glue and she cuts it and she i can't do that i can't do that level of detail so e leanen heavily you know and that's that's what kind of makes me different from other miniatures as they have for the most part they have good vision and and find motor skills and and depth perception that i don't have so i really have to lean heavily on what i do and

00:22:23

Speaker

you know i've seen comments i there i did a a video with test tested a couple years ago with um norm chan and one of the ah miniatures was was commenting on the youtube about oh this is a great interview but as soon as he mentioned digital design he lost me and it was like pardon part of my language can but fuck you dude i can't i can't um i can't work like you work my my eyes are are are shit i need

00:22:54

Speaker

to use the laser or the three d printer otherwise i can't otherwise i don't make things you know that's so right so i'm one of those people that really it's almost an absolute necessity for me because i can't do the real fine stuff anymore because my eyes are are so bad so ah you were pointing at oh my my furnace just kicked on is that oh can you hear can i want to now wonder no i can't hear sorry about that but um

00:23:25

Speaker

but you know so i at first i kind of like was kind of self-conscious about that it's like oh well i'm doing a lot of digital stuff and all these other incredible artists they're doing stuff by hand with their exacto knives they're rulers and their straight edges and paper and glue but doesn't mean that i have to do that but doesn't mean i have to work that way my way is doing it digitally i feel like i've i found a i found a way to kind of extend my my career as an artist by using these tools and to be honest

00:23:56

Speaker

i'm making stuff that looks better now than i ever had and you know what they're they're not going to be able to do that forever either and you'll be miles ahead of them technologically when they have to start leaning on that technology right and you know and and not not disrespect to anybody but well and and i and i you know i just i was and and his comment was like oh i'm sure he's a nice guy and i'm like why are you being a dick in the comments everybody else here is being being cool and yeah i went every once in while i go back to see if he had responded

00:24:28

Speaker

and want to blog he apparently he followed me on it he's someone who followed me on instagram but he went on youtube and was talking talking shit because i do digital stuff and anyway sadly that's generally somebody who's not comfortable within in his own place well and and and i sent him a message i said well one of these days when you get approached by norm from tested to do a video you can do it your life right you know what i mean that's like i i and very lucky to have been in that position to do that interview

00:25:00

Speaker

and yeah and you know i presented myself exactly how i how i work so when when you get that call do it your way and i'll be there talking shit in yourre comments if it it feels it feels a whole lot like a facebook group and yeah but yeah you mentioned that earlier and it's like i've i've left so many groups because it's like listen i don't need to be told what i have is garbage i need to i'm asking how to make what i have right and i just i i've i've kind of not

00:25:32

Speaker

not really i guess on ah on a mission but kind of a mission to prove to people that you can because there's kind of this stigma of oh well you just three d printed that period now mean it's just dismissed like it there's no value or no quality to it or yeah no worth to it because while it's three d printed well i have seen at see you're not a woodworker right right and and you know it's it's just i'm trying to especially now with these machines jeff you can speak to to the the bamboo machines how good those things are

00:26:09

Speaker

um it has really opened the door for me um to do some things that i really really couldn't and it's like well if i wanted to be a purist then i wouldn't be making any of this stuff i want to be a purist i would just be i would i would not be making things because i can't so ah if i'm not a purist then i'm going to lean on the technology and i'm goingnna make some pretty cool shit you know if he were a purist you'd be putting signs on bellagio right real yeah right yeah yeah exactly you know and and

Artistic Focus on Visual Appeal

00:26:43

Speaker

don't eat don't even get me started on people saying like telling me oh you know like you should light your things you should light no that's not i'm not if i wanted to light my signs i would i'm not i'm not in interested in turning this into some engineering electrical engineering project i'm i'm looking at making a ah sign you can sit on your shelf that's real pretty i don't want the the urge to be to to turn off the lights and let the let the three dollars worth the led take all the take all the glory when i spent you know

00:27:15

Speaker

for four weeks trying to make the rest of this sign look pretty so i'm i'm pretty happy with what i make and i'm pretty quick to shut people down if they try to tell me i need to do something different yeah you're you're very good at what you do and i even have even more respect for you now learning your limitation and what you're doing within those limitations that's amazing good yeah thank you i i if my my retina retina specialist told me that if what i had happened you know if it had had happen in like the sixty s i would just be blind

00:27:47

Speaker

now like the technology the the technology is real wrote but yeah public service announcement here if you start seeing flashes in your vision ah you start seeing if you i've always had floaters but if you start seeing thousands of little teeny tiny black spots floating around in your vision get to the eye doctor get to it an ophthalologist asap because those little black things you see that's parts of your eye floating around blood cells and pieces of retina and you know all the

00:28:18

Speaker

stuff so anyway just just a public service announcement take care of your eyes and don't hesitate because um you know i got real real close to losing vision in my left eye like within you know ah day or two because it was it was getting really bad and they had to do some emergency surgery to fix it oh wow that's's that's tight oh i've yeah i've had i've had i've had the fluid in my eye drained each eye drained twice like they can go in and like suck suck it out and then your eye just like refills all on its own

00:28:50

Speaker

that's a whole different topic i don't want to gross people out sounds like fun i ah you know i have actually thought about ah my future though in ah in a longer sense of the future as far as where am i going to be in my shop in you know i mean i'm what my early to mid fifty s here but you know i say twenty five years from now maybe thirty years from now

00:29:22

Speaker

where am what am i going to be able to do you know am i still i'm goingnna be a feeble old man i don't know that i can trust myself with the table saw you know a kickback could put me in a hospital you know right right i mean it would a normal person but i mean we even more so you know i mean even a mild problem would be you know but if i can still see and still use a mouse i can still design things on a computer and then i can make the machines create the stuff for me

00:29:55

Speaker

so the the fact like the fact that we can use a cnc or a laser or a three d printer to do all of the hand work means that as you became bless a to do things by hand you can have the machines do that stuff for you so that would mean that you don't have to just cancel i mean in the old days you know it's like

00:30:26

Speaker

my grandfather basically just had to like stop doing stuff in his shop once he hit a certain age but if he would have had the ability to do the the the artwork side of it with the mouse and then have the digital fabrication do the actual hand work part for you yeah then that'll extend your ability to make your art and your project you know another you know ten or twenty years i think

Balancing Art with Caregiving

00:30:57

Speaker

i think when i'm old and feeble i can still three d print and see and see stuff i just gotta you know well i'm living that reality now ah different limitations but um you know for those who who know me and those who may not i might be new to um you know i have a a teenage son with severe autism and epilepsy and i'm his primary caregiver my wife is a teacher and she works and she works really hard and my actual job is

00:31:28

Speaker

his care caretaker he qualifies for government support like we he qualifies to have some in-home what they call home supportive services and i'm his provider that's my actual paid job which i hope doesn't go away in the new year um but because of cuts to programs but i don't have the ability to sit in a workshop or in a workroom and sit and labor over things

00:31:59

Speaker

i have the ability to sit at my kitchen table with my computer and labour over a design piece but i have to be there with my son i have to be in proximity to him so i what i you know you talked about jeff you talked about when you're old you can still work at the computer and then send it off to the machine and still create the things you were you were talking about that i'm kind of doing that now because i will get up at three four in the morning when my son gets up and sit and dow

00:32:31

Speaker

two or three hours of design work i can stop i can get up i can take care of him i can sit back down and go back to work i can hit get it all the way i want it and i can send it to my bamboo the x one carbon i don't care if it's a twenty four hour print job that machine is so reliable i know that if i get it all set up right and i get the bed all prepped and everything i can hit start and i can come back tomorrow in the piece that i that i need is there and it's done and it's almost perfect enough to go on go on as is so

00:33:03

Speaker

i'm already kind of living your reality what you were talking about in the future like not being able to work in in the shop i'm already kind of there and so that's another reason why i lean so heavily on the digital stuff and i've leaned more into the three d printing because it's something i can i can do all the the complicated work and then my mind is free to do whatever else i need to do for my son or my wife while my three d printer is putting my idea into a physical shape whether that takes

00:33:34

Speaker

and hour or or twenty hours or whatever um and so that is another way the digital fabrication to tie all together another way that digital fabrication has kind of a i wouldn't be an artist without it because i don't have the time or the ability as it is i i tie up like half our kitchen table when i work even when i'm assembling things and i i have even learned to the point gotten to the point where i rarely even use like a wet glue like ca glue or epoxy

00:34:08

Speaker

wood glue um you know sometimes i use wood glue for the base but i have got my process down so that not only can i sit and design at my kitchen table so i can see my son i can also assemble at my kitchen table for the most part um because i don't use i i'm not using a lot of hand painting i'm not using a lot of glue again with no depth reception i'm i'm just a nightmare with with crazy glue like i i i can get it to within about an eighth of an inch of where i need it to be and that's not close enough

00:34:42

Speaker

for for most of the work that i do so i've you know i've been able to yeah i'm already kind of working with that reality where i can't i'm not safe doing these things so i yeah i do most most of my sign work is done on the computer and then um you know that that's just that's kind of where i'm at right now so there is a future in it jeff you can do it one of these days when you're when you're eighty five and and you're wanting to make the the latest and greatest um sevendimenional c andnc carved thing you'll be able to do it

00:35:16

Speaker

ah yeah yeah well you're gonna you're gonna some have a robot and you're goingnna somehow add time two your pieces somehow i don't know and and that's just it that's the the the yeah

00:35:30

Speaker

it's time like i'm ah i'm a disabled vt so i am also living i'm also living that lifestyle you know like oh i can't do that any more so i have to rely on a like if i had to use a hand plane i can't do it i can't twist you know yeah i own a landscape company that we're getting we're phasing out because i can't run a weed eater i can't twist with a weedier you know um so i rely on my c andnc it's a large it's ah it's big right oh yeah yeah um

00:36:02

Speaker

so once i get a piece on there then i can do that's a lot of material to work with you it doesn't have to move right i don't have to lift it um don't have to you know and i don't have the retinal issues but i do have you know back a can't bend and twist and things like that so we've had we've had to actually actually if you look my cnc is up on cinderblockt yeah i see that because yeah just to make it easier for you to didn't work just bending over to change a bit was killing me

00:36:32

Speaker

yeah right you know it's people have this the people have this there's this stigma around um certain assistive yeah well like assistive technology um you know it's like and okay so like my son he can walk he can he can he can he can walk he can get on on his two feet and he can get all around the house but like when we take him to disneyland i use a wheelchair for him because he will not be able to navigate through a crowd okay so that's an assistive

00:37:04

Speaker

technology i see i see um you know people give us give us a side-ey and they're like oh well he can walk why is he in a wheelchair and it's like well one mind your own goddamn business we're on we're on pirates of the caribbean you should be getting in the boat right now you know by and but but it's it's assistive technology so it's like okay well he can if if he if we go to disneyland and he's not walking on two feet is he is he not enjoying should he not be able to go

00:37:35

Speaker

disney england yeah should should you should you not be able to work on your cnc or should you not be able to do anything ah is because i'm limited because you're because you're limited you know should i be walking around with everything blurry because i you know glasses are some sort of an assist am i actually seeing things because i'm using glasses to see them you know so yeah it's me you know it's people who have the have the luxury of not needing that type of of an assist that i think are the are the the ones who complain about it the most it's like

00:38:13

Speaker

put yourself in the shoes of somebody who can't do these things you know would you would you completely give up making what you make if if you you know something happened or if you found you know the drummer for for for deaf leopardy lost his arm and he's he's been he's rick allen you know he's been playing drums longer with one arm than he did with two but yeah he's leaning heavily he leaned heavily into assistive technology should he not be drumming anymore you know yeah that's a good you know what i'm goingnna start just

00:38:43

Speaker

just that i'm glad you said that because what i'm goingnna start doing now or what i want when when these people rise up against ur to me i'm going to just smile at them and say what aren't you doing because you can't see past your disability whatever it is that's holding you but right whether it be just lack of knowledge or whether it be a physical ailment or whatever right but you start you talk about the the wheelchair stuff i've had twice now i i try not to use it because i feel like there are people who need it more than i do but i do have a handicap park and

00:39:16

Speaker

and if you i have one too yeah yeah yeah yeah use it i agree i agree and i use it when i'm i use it when i'm in bad shape and i need to use it and stuff like that but twice now in the last year or so i've had but's just let's just assume her name was karen

00:39:35

Speaker

like walk cast me and go yeah you don't look disabled and i've literally said what is disd look like right right right yeah you know i mean i and you know the best dancer that is from a distance you didn't look stupid

00:39:55

Speaker

right right good yeah soundss good but you know we talk and and this this is kind of a it's almost a conversation on repeat and it's not that i don't want to have it but it's like we always defend our use of three d printers and c and c machines and and vinyl cutters and and assisted you know digital fabrication equipment and that's why jeff you know i'm i'm so happy you asked me to join in on this little endeavor here to promote it and and make it ah commonplace or common conversation

00:40:27

Speaker

but if you really think about it all these people bitching about these machines there's an awful lot of these machines out here if they're so bad and so terrible why does everybody freaking own them right you know everybody's got a print well i don't have a printer but they're not but art enough to use them so they don't think anybody else should have the option yeah yeah um oh what i was gonna say what i was gonna say is what what what i try to do is i try to

00:40:59

Speaker

not be and i'm not ashamed of how i work but i try to be very open about how i work i don't print something and try to pass it off as oh i made this by hand you know what i mean i i will show close up pictures where like if you look you be like oh you can see some print lines in this piece if you get right up close you know i try and i have kind of a rule where like if it looks good at arm's length looks great to me

00:41:31

Speaker

you know like i i try not to um overthink things there are some miniatures where you can get like ah you know write up on a piece and you see more and more detail i can't do that but i don't try to pass off what i do as not three d printed or not laser cut and instead what i try to do is actually show people look this is actually there is a lot of three d printing in this it might not look like it because it's a really good well- thoughtugh out three d print made on a good machine

00:42:05

Speaker

um but i tried to i try to not hide that i try to show people that you can do really really neat work especially nowadays with the technology the machines that available you can do really incredible work with a three d printer um and so i try to show people yeah like like that last piece that i made that it was kind of pink and there was a lot of metal a lot of shiny metal in my stories i went and broke down what each piece was to show people this is this is lasercut acrylic this is a three d print with styrene on it i try to

00:42:40

Speaker

rather than kind of be ashamed if some people probably think i should be that this is how i work i try to shine a spotlight on it and show people no this this is how i work this is you know if if if you if you want something that hundred percent handmade down with ah with a knife and all of that hire somebody else but if you want a really awesome looking finishedpiece ah sign that looks like the sign that you want then i'm your guy and i'm going to make it the way i make it

00:43:11

Speaker

um it doesn't have to be it doesn't have to be made that other way it it can be if you want it that way you know find somebody but if if you like what i do this this is how i do it and i you know like i said i've been i've kept myself busy for years now i think it has a lot to do with the detail and it has a lot to do with how you're printing things i mean if you took an asvg you extrued a couple spots and you sent it over to your printer and you slapped it up on the wall

00:43:42

Speaker

then i'd be well maybe that was sort of low effort and not impressive work because you know just told the printer to do some stuff but once once you've scaled things to the point i mean you've scaled your details in and you you've designed the sign as three hundred individual parts that layer and nest in it and and you can just

00:44:14

Speaker

snap the pieces together with tolerance because you've got it so tight that you don't even need clue correct with three hundred different individual pieces that are snapping in that is not i extrued an svg and pushed the easy button and and just pop out over here right so right i can kind of see where some people get annoyed by what they perceived to be an easy button where it's just like well they didn't do any work they just

00:44:47

Speaker

downloaded the thing and then they didn print and so to be fair if you i mean you can get a bamboo you can go into the maker worldl website you can download ah flexy dragon that's thirty six inches long and you can load roll of filament and push print and it has literally no skill or effort you just download it and you push print

00:45:19

Speaker

is that thirty six inch dragon super impressive well it was impressive to the guy that modeled it but i'm not impressed by the fact that you managed to download it and print it correct but see there's lines where there's art there there was art there the art wasn't you downloading it and printing it but the art was the original guy who original i'm sorry person who designed it right the the original person who did the modeling you you are

00:45:51

Speaker

in that case i have a thought and it parallels im i'm try get out before i before i before i lose it um i am not a graphic designer i am not a i'm i'm not an an artist who i'm not good at creating original things i'm good at taking something that someone else made and translating it into something that i can make and so kind of in that scenario

00:46:22

Speaker

the you know you talked about the guy the person who created the dragon that was the artist and the person who just kind of downloaded it and printed it out is not the artist the in my in my the way i see things the artist is the person who designed that the sign that i'm making the artist is a person who created person or person persons who created the original artwork i'm just a translator i am just in this scenario i'm the three d printer in in like in your scenario

00:46:54

Speaker

i'm kind of the person who is i'm kind of downloading all of their all of their design and everything yes i am translating it into what i'm doing but i'm not i'm not creating it um from scratch and that's why i have trouble a little bit of trouble with the the phrase artist because really i'm i'm more of a um replicator you know what i mean it's there there is a upon homage to them yes there i'm i'm i'm i'm copying someone else's art work there is art

00:47:25

Speaker

if you want to expand the definition of art there is an art to what i do but the artwork that i create most

Imagination in Design Creation

00:47:33

Speaker

of the time was was created by someone else and i'll give you a prime example of of my limitations the sign that i just made this coral cor signed it was a sign it was ah it was on route sixty six in st louis every picture i can find shows the face of the sign it shows the reader panel it shows the column it shows everything and i can work with that i can take a blurry picture and and and

00:47:58

Speaker

get it you know get my design sharp and looking good but there's a work platform on that sign for the person who changes out the letters for the for the read like that you know um air conditioning color tv private garages those those big letters there's a work platform in all of these photos these maybe twenty photos of the sign that i could find i'm only seeing it in i'm seeing the edge of that i'm seeing it kind of like i'm not seeing underneath it i'm not seeing above it

00:48:30

Speaker

all i'm seeing is just um metal looks like a metal rectangle and if i make my sign where it's just a metal rectangle it's going to look like shit it's gonna be like oh well he he's got all this detail but then this this work platform is just a ah printed recting it's like the monolith on on you know the two thousand and one space odyssey on the moon it's just ah it's just it's just a a big rectangle and so and put a side book on it right so what so what i had to do was um

00:49:03

Speaker

is i had to imagine like okay well what what could this be i know it's it's a platform okay well a platform probably has like a metal grate on it you know for for traction um it probably passes through so like rain and snow doesn't collect on it like you can probably see through it and that was like one of the last things that i made on that piece because it took me so long to figure out well what do i want this to look like because i had to come up with it on my own it wasn't something it wasn't the letters on the sign it wasn't the big shapes that someone else had already decided

00:49:37

Speaker

it was something that i'm having to create kind of from scratch from my own mine and so i did and it looked really good i i settled on a design that has some some cross beams and it has a has a great and and same thing in my photos you don't really see it but if you look at it from above you can see down you can see it but i have trouble with those types of things i'm not great ah coming up with my own designs i've had people ask me to design things for them like man i am not i haven't taken a single graphic design course ever

00:50:10

Speaker

and um another thing on that sign is there's a couple little columns a little um like brick they're like ah white stone columns with a couple of chains between them those also took me the longest to figure out how to do because it's not something that i could three d print it's not something i could lasercut it's something where i'm going to have to actually sit with with clay and materials and sit and kind of sculptped it out a little bit so you know i do have my limitations i am not there are a lot of things that i am not really

00:50:41

Speaker

great at and and those are those are the things it's funny those little stone columns if you see that sign those two little stone columns took me longer to figure out than the rest of the entire sign because with the entire sign i knew what i needed to do i knew i can three d print this shape i can cover it in styrene i can lasercut the acrylic face i can do all this it was the kind of creating it from nothing is the non-digital fabrication that gave me trouble and yeah any i want

00:51:12

Speaker

disagree with you on whether what you're doing as miniaturization counts as art i career where i was going i want to disagree with that completely here because by by your logic a guy who is a fantastic painter say a rembrandt kind of guy yeah pick i already see i already see your point coming like it does landscapes okay now say that you're gonna sit down and you're gonna paint

00:51:47

Speaker

ah a painting of a landscape now in his eyes he's not the artist because in his eyes the earth is the art and the mountaincapes and the trees was just such an artistic shot that he just captured what he saw and translated it onto the paper and he didn't actually create the art he just took what he saw and he translated it and he put it into a different form

00:52:23

Speaker

so that other people could see it later but he didn't create that image he didn't create the image he saw the image it was there there were those trees and there worth of the sky but he saw it and he was able to translate that into the paint and yeah you look at the pictures of the original sign and you figure out how you can recreate that andnna boy one

00:52:54

Speaker

twentieth scale or whatever the random help if it is right but you know whatever was you know ah hundred feet down to eighteen inches right and you managed to scale that down and use seven different types of materials with four different kinds of tools and it all cohesively comes back together and looks exactly like the big one and so somehow you feel that

00:53:25

Speaker

wasn't art i think i think the finished pieces is art i i just i struggle i struggle with the the term artist i'm a little more i'm a little more open to it but i i i need to be able to accept myself as an artist and not see it as taking away from the people who did the original stuff that's what it is is i as i don't want to i don't want to try to i don't want to look like i'm trying to be like oh you know the people who made the stardust the original stardust pylon sign from the ad art in um

Reflections on Artistic Role

00:54:01

Speaker

things in stockton or sacramento and they shipped the pieces to vegas i don't i want to make make it clear that i don't and that i'm not trying to equate myself with those people you know what i mean you're using you're applying humility to your life and that's ah that's an honorable thing and the interesting thing about being an artist is you don't get to decide whether you're an artist the consumer of your material gets to decide whether you're the artist or not right right yeah you know that that is a good point that is a good point yes you both you know you both wheel

00:54:33

Speaker

good points we see it we see your work or anyone else's work i see i see jeff's work and i'm like wow you know that's something i can't attain right now ah or maybe ever so to me that's an incredible skill and it's art artistic or it's creative or it's it's it's ultra maker you know it's all traprinology right but you're a very humble you're a very humble and and and and amazing person so that makes your work even more impressive

00:55:05

Speaker

you know because if you came out of the gate going i me perfect sign recreatoror you know and you know now now we're having a conversation about what you are aren't right right right yeah you're you're not an artist but you are an asshole yeah

00:55:24

Speaker

there's a lot of interestingly i' i've had people tell me that yeah and that's you know that's yeah you know i yeah you're right i just i try not to i don't know i you know when i yeah when al we we messaged yesterday and you said you were excited to have me on um i said i'm just a dude i'm just a you want any i don't yeah i don't see i don't i don't we're all we're all you know we're all just people trying to you know to trying to to to do what we may what we do and you know if we need

00:55:57

Speaker

we need some some tools to do what we do awesome like you know like that okay my my my response whenever somebody rarely now because i think i've shot down most of the assholes over the years and the people people have seen me do it and maybe they they're not wanting to to get me riled up anymore but i tell people like the the stardust sign that i made this summer that i took to las vegas and i put it on the original spot of the stardust sign um that was that's like the pinnacle as a peakek of what i of what i do

00:56:32

Speaker

and yeah you know i i not that it has happened but i would challenge somebody make that sign make it the way i did it to the level of detail that i made it without the tools that i used it doesn't exist it yeah you know there are literally thousands of like point eight millimeter bulb that are accurate to what was on the real sign

00:57:03

Speaker

but they're they' like i said they're they're point six or point eight millimeters printed out there's no way i don't think i mean you know there's always exceptions but i don't know that somebody could actually sit and and make it and make it look as good as they as it does and i'm gonna brag about that fucking sign looks awesome sure um but but without thank you and without using tools like i did it doesn't exist you know so there's there's there's that side of it it's like if if people want to talk trash about digital fabrication it's like well think of all the things that that wouldn't exist without it you know so

00:57:38

Speaker

um yeah there are signs that i've made that that people there there are other people who are making signs who aren't three d printing they're they're bending wire they're doing um really good work there are people there's now several people who actually make miniature science um and i view that as a good thing i don't view it as like a ah competitive thing i want to learn from them and um i have learned from these people but um you know it's a you you do what you can with what you've got if you can make it make stuff and you don't need the digital fabrication fantastic but there are some of us

00:58:16

Speaker

who who one do need it and two who who are doing really amazing things that couldn' be done without it so what's a what's a um that when we were getting ready to start you were talking about your workflow what what is what does your workflow look like you talked about you know you're you're ah you full-time caregiver for your son right and like you're you're able to work on your kitchen table and stuff like that right like do you have do you have a monday i do this tuesday i do this

00:58:47

Speaker

wednesday ah not at all not app ah all not at all controlled controlled chaos is your is your it it is is whenever whenever i can i work when i can't um when i you know i have a i have a it's not entirely unique i know a lot of people who have have kids like mine but um i have to be able to just drop everything that i'm doing at a moment's notice and course intend to my son

00:59:18

Speaker

but also my work is the same way where it's like oh i've got twenty minutes let me sit down here and knock this out you know um it's taking me longer these days to to make my signs just because i'm i'm kind of trying to find more of a work life balance and my son's a little been a little meatier lately but um i i'm losing i'm losing my thoughts here um my workflow yeah my workflow so i really there isn't there is no

00:59:49

Speaker

workflow it's just it's like it's a bunch of disjointed little sessions sitting on the computer and little pieces here and there and print a piece and i'll throw it in it in a box and eventually i'm like oh i have enough stuff where i can start standing this up and start turning it into a structure it's it's funny because i share with the clients i share progress pictures like test pieces and this is what i'm doing this is how i'm going to approach this and and it's funny because it'll be two months of me sending them pictures of all these all these separate items and all these things and then

01:00:23

Speaker

over the course of one weekend they go from just a bunch of pieces in a box to like oh now we have a standing sign and in two or three days i'm going to be completely done you know so it's like it it um it's real slowgo at the beginning but once i once i solve all of my little mysteries i don't jeff you probably do this like small scale tests like like when you were doing your your test with your logo with the with the the printing you probably didn't just did you start a meet right there like your finished piece

01:00:54

Speaker

or did you do some test pieces first like to test your theory out that this that that way you have your layers set up and your your your threads and all did you test that small scale or did you go right to the finished piece um well i mean i did some prototypes with the ah threads to make sure that i knew how reds worked but right once i made sure that the threads were working i just went straight ahead and printed my logo and that's and that's how i work is i will do

01:01:26

Speaker

small scale test so a lot of my workflow is i'd say half of my time making a sign is just tinkering just experimenting like how can i make this right up to the edge of possible like like um a lot of times my workflow i start out trying to do too much like trying to make something too complicated or make a ah channel letter that's too thin and so most of my early time is just kind of

01:01:58

Speaker

experiments just trying to figure i look at a sign and i figure out sorry i'm drying out here i will look at a piece and i will figure out what is the most complicated piece that i need to make on this sign is it ah certain type of neon or a certain shape or letter and i will solve that problem and once i get that solved it's okay what's the next and hardest thing that i need to accomplish and i will so my workflow generally i will start out with just kind of not even trying to make a finished piece just testing a theory like can i do

01:02:32

Speaker

this certain this certain curve can i get this to look good can i get these pieces to fit together um so my my workflow is a lot of problem solving a lot of experimentation and then bam at the end all of a sudden i have a sign standing you know so it's there is a general elephanteater yes yes exactly yes one bitte at a time one one bitte at a time yeah and and and lots and lots of barbecue stuff um ah but does does that tie in with your okay go theory

01:03:06

Speaker

it does in and yes and for those unfamiliar ok go rock band always tell people they're the guys who did the video where they're dancing on the treadmills like in two thousand and seven if you ever saw the video um went viral one of the first like viral music videos but they have and and i don't use this for everything but when i have like a a complicated piece i'm going to work on you know you yeah there's a spectrum there's picture of spectrum from left to right on the left

01:03:37

Speaker

is impossible and on the right is possible okay so you and and all points in between go from somewhere somewhere along that point you move from impossible to possible and as your skills improve that line shifts the area that is impossible gets small okay so what they do a lot of times with their with our music videos is they will start out with whatever it is that they're doing

01:04:08

Speaker

they will start out on the impossible side they will make things and they won't work i will three d print things that fail they' too thin it's just two it's just not working but what i will do is i will tweak it a little bit and i will move it on that spectrum okay well that was too difficult let me move it over to the right let me move it more in the direction if possible on this spectrum and you get to a point where you cross over from impossible to possible at some point on that spectrum you jump that line and now

01:04:43

Speaker

the thing that you're working on it is possible to do it and if you live right on the edge of that line if you move from impossible you jump over just into the range of possible that's where really good stuff happens like jeff a lot of the stuff that you a lot of the stuff that you do jeff that i see is right there on that line it like how in the world is he doing that well he has worked it so much that he has crossed that line on that spectrum from the impossible side

01:05:14

Speaker

to a possible any stay right there and and that's why the stuff that you do is so neat and so um you don't see a lot of people doing it because you have pushed yourself you know what i mean it's so that is kind of like my okay go theory is i will try to o i will do a lot of things that don't work like hey well if i make this point two millimeters thicker will it work and i'll print it and it won't work whoa maybe if i make it point four millimeters wider suddenly i have a ah viable piece it's like okay well awesome it's gonna look good because it is so

01:05:49

Speaker

close to to failing but it's not it's it's saw it you know so i tried to hear that you're kind of guaranteeing you're guaranteeing the best possible outcome with the tool and ability as opposed to starting as opposed to starting at the easiest end and going well that worked it's good enough correct and that's that that and that's where and i you know i kind but i've talked to jeff a lot yeah i talked to jeff in the in the past about that about how

01:06:21

Speaker

he not not content with just being able to cut things out you know two-di dimensional things you're you know you're like okay well now what's next what let me move further on the spectrum towards the impossible and might even cross over into where okay well this isn't working so let me tweak it back ah you know a percentage at a time until now boom we crossed over into possible and that's where the good che is you gotta sit on the line yeah yeah the line is that's fine

01:06:53

Speaker

gentlemen that's some life lesson shit right there well you can you can think you can you can thank okay go for that one because i saw it on a youtube youtube on an interview they have a video of if people want to not ah kind of an example of what i'm talking about um there's a song that's called this too shall pass and there's a music video they took ah a studio building ah two-st story building in l la and turned the entire building into a giant rub goldberg machine it's just a chain reaction and it's all one take

01:07:25

Speaker

and it's all set to the song they tweaked it so much so like things are happening in this video along with the beats in music and that's because seen this you probably have and it's and it's because they sat and and it failed and it failed and you know they did like eighty takes but on that eightieth takes it all worked and it's incredible but they were they spent months on the wrong side of that line and it just tweak it a little bit little bit little bit and then they got it just over that line and they caught it on video

01:08:00

Speaker

and it's incredible and that's that's how those guys work and they they are a big um like creative inspiration to me so i've got two quick one one just for chris and then one for both ah if i if i might for chris what's what's the origin of root nine son ah you to live on group nine somewhere no no no um ah my when i first made my instagram account that was going to be my quid account i started it out as it was called small you later

01:08:33

Speaker

instead like mill youator it was yeah all you later because that's go to several things but i thought you know what that's not professional enough and so i just started um i started i started thinking well it's like well there's root six i'm gonna be i want to make signs and there's root sixty six but you know okay i love route sixty six and the idea of root sixty six in the road itself and everything but all the shit you find in the stores with route sixty six logos on it it everywhere you go i don't like any of that you know that's

01:09:04

Speaker

yeah but so i didn't want to do like i didn't want to associate myself anything with like the root sixty six nine is my lucky number i won't go into it but i've got there's a lot of nines in my past and nine is just my lucky number and so i thought well i want to put a nine in there and i thought well what about like root nine oh and that rhymes of signs root nine signs boom boom boom that' something the word root has five letters signs has five letters it's it can be symmetrical i can make it square i can make it round

01:09:35

Speaker

i can put it on a shield like ah like a road sign um i live right next to highway ninety nine that runs up the center of of of california i i can see it from my window it's about a quarter mile away i thought about root ninety nine signs but that was it was more of that's a little too specific and i didn't it doesn't flow as well um but root root so root nine signs is just kind of root nine is an actual in new jersey they call it highway nine or route nine it is an actual

01:10:06

Speaker

there's root nines everywhere but it's just um it's just a good name you know it's just it it's something easy it it think it's one of those things where like when you first try it out it's like like when you first name a pet and like oh are we really goingnna call this dog sterling you know cause i have a courtney named sterling and the first few weeks that kind it doesn't roll off the tongue but now like i can scream it at the top of my voice you know across the backyard with no problem because that's just what it is so it took a little while for me to get comfortable with it but um yeah that's just where it came from just just kind of made it up

01:10:40

Speaker

i live on county route ten right here it's a rural rural route but i am surrounded by root nine g root nine h root nine nine j okay so you know funny story my favorite the sign that i that really made me want to make signs was is called moon motel oh nice who's that that is charlie our corgi mix oh nice but yeah my am my my sterling hes he's a ah i got him from a breeder his his siblings are all showdogs in canada and meanwhile he's here at my house

01:11:13

Speaker

just rolling in the dirt and he's he looks like he's half court halfco half castc cow um yeah yeah i we seen every seen that meme i am domesticus whatever i am yeah my dog i am to i guess say no why um oh but the sign that made me want to make signs was moonel and it was in new jersey it's this incredible space age sixtyties motel sign

01:11:44

Speaker

just incredible sign and um years like two years down the road after i' had already named my my shop route nine signs and i was i was making that sign again and i was on street view and i was tuling around and i realized that this sign that made me want to make signs is actually on route nine in new jersey so i was like oh well there you go if i ever had any questions at all whether or not this was the right name it was because my favorite sign or least my favorite nonlaw vegas sign

01:12:15

Speaker

is is on route nine in in new jersey tell so and then the question for both of you and it's an opinion and then i'm i'm literally asking because i'm struggling with it um freedom units versus millimeters as all this technology starts to roll like i'm dealing with a sadly i lost a ah laser source in my bland new fiber laser they're in the um but they're like all the techs are talking in millimeters and i'm like i don't

01:12:48

Speaker

i don't do millimeters bro he's like you do the software just does it in the background and i'm like it's such a struggle for me is this something that i need to just embrace and start using millimeters jeff do you want to go first or do we want to go at the same time yeah yeah yeah um i i don't i don't even know but i just i'm making an assumption assumption that that jeff that jeff has evolved

01:13:21

Speaker

to the millimeters to the me yeah i mentioned it on the i was talking about this on the i'm on our last episode but that's only been out for a few hours right now so we probably haven't heard that yet but the i don't think in millimeters yeah that's a problem but i have printed a three d ruler that does like a hundred and twenty ah or something

01:13:52

Speaker

ah yeah no it's maybe two hundred something it's it's you know at six or seven inch ruler but it's all in millimeters and centimemetters and i keep that sitting right here next to my computer because when i'll it's like i'll download something and i'll want to scale it to be the size i want before i print it but when i download it and it says it's seventy three centimeters i can't just visualize seventy three centimeters i don't know i mean if you told me it was goingnna be about two inches i can

01:14:24

Speaker

picture that i know how big two inches is but the seventy three centimeters doesn't work for me in my head so i've got a ruler i pick up the rule i keep it right here at my desk i pick it up and then if i need if i if i want to know what seventy three centimeters is i put my fingernail right in the seventy three and i look at it and i say you know i want it a little bigger than that let's make it one hundred i can see that in front of me and then i can put that into the computer but

01:14:55

Speaker

i'm i you know i think if i keep doing this printing stuff for another year or so i might actually get to the point where i can actually think and where i can actually visualize millimeters and centimeters a little better okay i mean i can visualize an inch i know how big an inch is when i i can think about how big a big it's in my head but the millieers not so much it' just and but it's it's just repetition and use the more you use them the more yeah yeah

01:15:29

Speaker

um that's fair reasonable and you keep and analog source handy like a physical ruler that you can just pick up and you can hold it and you can say okay well this right here is thirty centimeters i can see it okay now i can just decide whether that's enough or whether it's too much and i can scale from there i don't mind working with it i just

01:16:00

Speaker

i'm not capable of thinking in it yet but right i will being there's no getting around it future is really in there if you're goingnna be doing stuff with lasers and three d printers it's almost inevitable you can run a dnc on ah you know fraction you know thousands you can run thousandsth of an inch on a cnc and i still run my shape oo and inches although it's ca full of doing metric as well

01:16:32

Speaker

but so i mean it's you it's it's worth it i think you should just you know start with the analog you know you you pick up the ruler and you look at it until you know what thirty centimeters is you can just pick something up and look at it and go well that's thirty centimeters

01:16:51

Speaker

right now i use ah my caliper i upgraded my calipers are still not like sterrets or anything but it's a decent set of calipers and i can let like

01:17:01

Speaker

it's point ah one and then i just hit go and it tells me that that's and know it's point ah one millieter so zero zero five inches so i did you burn it with money with my caliber right but but you if you're working in millimeters to begin with you don't have to do that conversion it's just i mean it's just it's it it's it's a step yeah what i mean yeah it is a step and for me i have fully embraced the metric system i everything that i do is in the context

Preference for Metric System

01:17:33

Speaker

of of millimeters um i don't even really work necessarily work in centimemetters i work i work in millimeters and and fractions you know like tenths of a millimeter but what um

01:17:47

Speaker

i have a good understanding now i've been doing it that way long enough that i know that okay ah when i when i talk to my clients i talk in terms of inches and feet but with me my workflow it's all it's all about um this all metrics i'll tell somebody oh this is going to be it's going to be about six inches wide but in my head i'm like well that's a hundred and fifty millimeters it's give me about you know i heed i say give me a about six so if they if there's someone who throws a ruler on it when they get it and like well it's it's a sixteenth of an inch

01:18:19

Speaker

bigger than he said it was going to be well i said it was going to be about that but i have um these machines that i work with are so precise that i can make changes that like a tenth of a millimeter to something and that changes the tolerance the fit and it's just i mean i could do the same thing with you know inches and and core you know like infractions and and all of that but i just the software every every time i i turn on my glo fors i have to click it over to to millimeters

01:18:54

Speaker

um yeah my design software that i use it has it has both but i um i use i use millimeters i can tell you know three hundred is a foot six hundred is roughly two feet and again when i'm when i'm estimating a size for somebody it doesn't matter if it's a little bit off but when i'm actually and one of the things that i have learned is a little cheat that i have i have ah started to do because i don't and't write anything down i don't i don't do it but if i draw if i draw out a piece

01:19:27

Speaker

if i'm making a ah sign and i i and i'm looking say i'm looking at a photo on my computer and i'm kind of drawing the shapes on top of the photo can say it's a really good photo and i can the perspective and everything is right and if i draw out a square to match a square that's on a sign and it's ah hundred and forty eight millimeters wide hundred and forty eight point two millimeters wide i'll cheat it and just round it up to the nearest five i'll make it a hundred and fifty millimeters or

01:19:57

Speaker

if it's a hundred and forty six and a half when i draw it i'll cheat it down to make it a hundred and forty five and then that way if later on i'm like oh what was this was like if i lose the file or whatever i can take the piece that i made and i can throw it on my calipers and be like oh the caliber says it's a hundred and forty five millimeters that's or it's a hundred and you know it just it helps me kind of keep track i can um i will kind of fudge things to make it a nice

01:20:28

Speaker

you know increment of five or whatever um which you know when you're talking about fudging it ah a couple of millimeters in either way you know three millimeters is like an eighth of an inch for example and on a sign that's eighteen inches tall ah an eighth of an inch isn't ah much you know nobody's going to notice that well that box on that sign is and eighth of an inch too short nobody's going to notice that but i do that to try and give myself um it's easier when i'm dealing with like if i offset a piece or i inset a piece by two millimeters while it's going to be

01:21:01

Speaker

it's going to be either it's either going to be ah a five it's going in in a five or a zero plus two in this direction so um i tend to kind of um standardize my my stuff a little bit i so i do work in millimeters but i try and be real um kind of consistent with it i try and work in and work in in like five s if if that makes any sense just just because i i will forget be like oh i can't i can't remember hundred and forty seven point eight three but i can remember one hundred and fifty right i've i've got a really good friend in australia and that's why i own this

01:21:36

Speaker

inches but tap measure so we can talk um and he seemed he apparently that's very and don't want to say americans only but we are so concerned with a thirty second and a sixty fourth and and all that kind of stuff and when he builds furniture in australia it's one forty eight you know he'll go measure for a desk and if it's ah say a desk is a hundred and forty seven but if he measures a hundred and forty seven he'll call it one fifty yeah like they they just simplify everything they just round everything and he's like

01:22:09

Speaker

what are you going to stress out why are you stressing out over an eighth of an inch you know who cares if it's an eighth of an inch bigger or smaller you know unless it's a you know a precision fit but if you're i guess what i i'm trying to convince myself to do this i tried to switch to metric years ago and i just i just started tripping over my own face but now i find myself overcomplicating the math because i have to go into millimeters in the machine but i'm designing in inches and it's just so i need to just

01:22:41

Speaker

yeah i am bilingual i can i can i can think in both i can do rough rough um translation i can do a rough ah you know i can be like oh well this this is if this is sixteen inches that's roughly four hundred millimeters um i don't go the next step and say well that's forty centimeters or whatever you know i don't i don't i don't even it's like i were just straight millimeters millimeters and tenth and tenths of millimeters i don't i don't be like well this is six six centimeters and you know six centimeters and five mill no i just say it's sixty five millimeters

01:23:20

Speaker